Nearfield Systems Inc. (NSI) has developed a new spherical near-field scanner, NSI-700S-300, that is capable of testing stationary antennas over wide angles with accuracies and speeds that historically were only available from planar near-field systems. It is ideal for wide angle satellite and radar antenna testing.

Nearfield Systems Inc. (NSI) has developed a new spherical near-field scanner, NSI-700S-300, that is capable of testing stationary antennas over wide angles with accuracies and speeds that historically were only available from planar near-field systems. It is ideal for wide angle satellite and radar antenna testing.

The planar near-field technique is often used for testing antennas of higher directivity (typically >15 dBi), and allow the antenna to remain in a fixed orientation. However, planar near-field scanning cannot provide good sidelobe coverage out to beyond about ±70 or ±80 degrees. Spherical near-field measurement systems can avoid that limitation, but until now have required that the antenna be moved about one or both axes to accomplish the measurement. NSI, in introducing the NSI-700S-300 Arch Roll Spherical Near-field Scanner, has overcome this limitation, allowing high precision spherical near-field measurements beyond ±90 degrees, without the need to move the antenna (see Figure 1).

Figure 1 Typical hemispherical near-field data plot measured on NSI-700S-300.

The challenge was to design a spherical antenna measurement system that would allow fast and accurate electromagnetic field measurements for a stationary antenna by using only probe motion. The advantages of testing a stationary antenna include:

• The antenna can be measured in the orientation in which it will be used. This way antenna flexure due to a changing gravity vector does not corrupt the measured patterns.

• Manufacturing support hardware costs for the antenna can be greatly reduced. For instance, expensive slip ring assemblies and flexing power control cabling used for active thermal control are no longer necessary.

• The antenna alignment support equipment is much simpler and can be set up in the manufacturing assembly area, and simply rolled in to the test range without elaborate fixtures, mounting procedures, or alignment steps.

Figure 2 Pictorial of NSI-700S-300 arch roll spherical scanner with inset image.

The stationary antenna approach requires an electromagnetic field sensing probe that moves over a hyper-hemispheric surface enveloping the antenna (see Figure 2). The probe is precisely positioned in space by a high precision structure augmented by dynamic motion compensation. The scanner can complete a hyper-hemispherical multi-beam, multi-frequency antenna measurement set of up to eight feet in diameter in less than one hour. The arch rotates continuously at 30 degrees per second during the measurement process.

The new Arch Roll scanner product line opens the door for accurate wide angle hyper-hemispherical measurements of stationary antennas. Its design not only eliminates the need for slip ring assemblies to the antenna, but simplifies the meticulous alignment procedure required for accurate measurements on traditional spherical scanners.

The NSI-700S-300 Arch Roll Scanner’s proven design allows for frequency expansion to millimeter-wave measurements. The design is also adaptable for symmetrical 1g loading measurement requirements. It is ideally suited for satellite and radar antennas that require precision testing of a fixed antenna that cannot be moved or rotated during a test cycle.

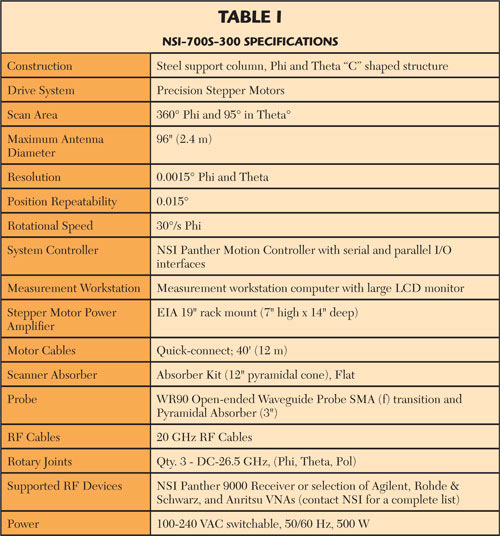

Other unique features of the Arch Roll Scanner include (see Table 1 for a full list):

- Sub arc second encoders combined with structural deformation correction.

- A 4" travel radial stage for accommodating a variety of probes.

- Specially designed algorithms for dynamic probe position correction of the arch roll configuration that allow ‘on-the-fly’ probe position correction to maintain a probe position accuracy on the order of 0.0025 inches rms.

- An RF subsystem that is capable of measuring thousands of frequencies and beam configurations.

The NSI-700S-300 Arch Roll Spherical Near-field Scanner together with NSI’s Panther 9000 RF subsystem and NSI 2000 antenna measurement software deliver spherical measurement with unprecedented accuracies and speeds.

Nearfield Systems Inc. (NSI)

Torrance, CA

e-mail: sales@nearfield.com

www.nearfield.com

RS No. 302