5G private networks are the talk of the town—for good reason. Revenue from 5G private networks will grow from $1.6 billion in 2021 to $65 billion in 2030.1 However, the road to 5G private networks is paved with challenges that manufacturers and their partners must overcome to ensure network coverage, connectivity and stability.

The manufacturing sector will gain the most by adopting 5G private networks, and tomorrow’s smart factories will need to implement the following applications to achieve this potential:

- Wireless, real-time, closed-loop control and process automation

- Production control using artificial intelligence (AI)

- Design and production using augmented and virtual reality (AR/VR)

- Wireless and collaborative robots, including automated guided vehicles and autonomous mobile robots

- Massive numbers of wireless sensors

- VR-based support and training of remote teams

- Advanced predictive maintenance, monitoring and tracking of time-sensitive assets in the factory and during transit

- Big data analytics making business decisions in real time.

For operational efficiency, manufacturing will use massive numbers of wireless connections on the factory floor, each requiring ultra-reliable, stable coverage and connectivity; ultra-low latency; and high downlink and uplink data rates. Applications that require high uplink data speeds and ultra-low latency are rare in the wireless consumer market, but these requirements are paramount in Industry 4.0 applications and are achievable with 5G wireless networks.

While we often hear about the implementation challenges of 5G private networks, successful deployment begins earlier in the life cycle and continues well beyond installation. All the components—devices, radio access networks (RAN), open RAN, the 5G core, multi-access edge computing (MEC)—must work together at peak performance and end-to-end network performance be optimal. Testing the RAN at site acceptance is not enough and may result in blind spots. This article explains the four steps needed to optimize the performance of a 5G private network, beginning with an overview of 5G private deployment models, standards and 5G-enabling features for context.

DEPLOYMENT MODELS

Deploying 5G in a factory can take different forms. A typical network contains three elements: 1) user equipment, including connected sensors, cameras and controllers; 2) the RAN, i.e., base stations and user equipment connected wirelessly; 3) the core network, which routes information among the mobile clients and edge network elements, handles billing and authentication and tracks the location of the mobile clients to maintain the wireless links.

A 5G private network can be deployed using a dedicated and isolated setup, i.e., standalone or by using a public wireless service provider. The core network can be at the site or in the cloud, and the network can be managed by a third party or a mobile network operator. Each option offers different levels of security and has specific service and network management needs. Choosing a deployment model requires careful consideration of the use case, the manufacturer’s technical knowledge and the business strategy. Research indicates two-thirds of manufacturers prefer to fully own and operate the private network because of security concerns, such as keeping production data in-house.2

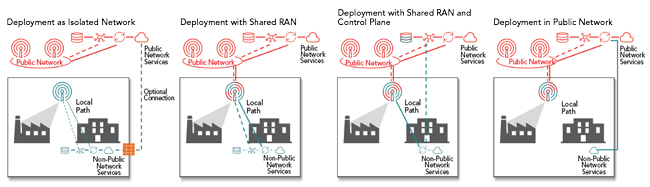

Figure 1 shows four deployment options for 5G private networks. The most isolated private network implementation has the radio, control plane and data plane implemented inside the factory. It does not share resources with the public network and is the most secure way to implement a private network. Another model shown in the figure comprises a private network created by reserving a “network slice” from a public wireless network provider. Network slicing enables operators to allocate a portion of its network resources for the application. These resources are dedicated to the manufacturer to guarantee specific service requirements for latency, reliability, mobility and throughput.

Figure 1 Deployment options for industrial 5G networks. Source: 5G-ACIA.

STANDARDS AND USE CASES

5G’s foray into the industrial world is based on the development of standards. 5G private networks also require involvement from governments, for allocating spectrum and regulating civilian and military applications, and from industry for trials, testbeds and ecosystem solutions.

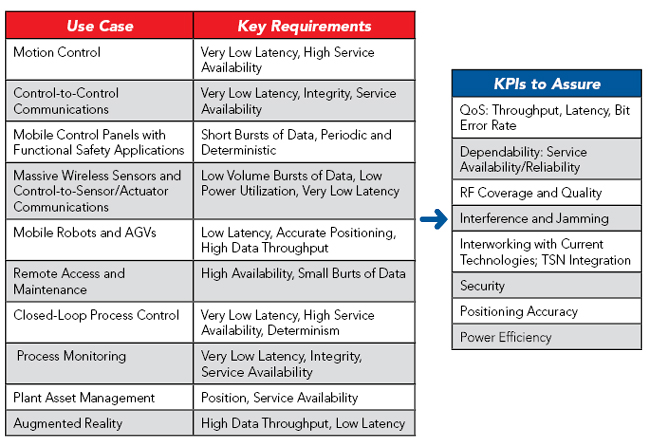

Many industry organizations participate in the development of standards for 5G private networks. The most notable are the 3rd Generation Partnership Project (3GPP) and the 5G Alliance for Connected Industries and Automation (5G-ACIA). The first 5G standard release (3GPP Release 15) focused on consumer services. The most recent release (Release 16) and the upcoming Release 17 offer capabilities for the industrial space. Release 16 introduces significant enhancements to achieve low latency and Release 17 will increase the integration of 5G with time-sensitive networks (TSNs). 5G-ACIA has played a significant role in the development of the 5G performance targets by defining the use cases for 5G in industrial applications. Figure 2 lists the use cases, their key requirements and the key performance indicators (KPIs) for these requirements.

Figure 2 Industry 4.0 use cases, requirements and KPIs.

5G ENABLING FEATURES

MEC — MEC is essential for many industrial use cases, as it brings computation physically closer to the user and helps achieve lower latency. MEC enables offloading computing demands from devices that need a lot of compute resources, like AR glasses and wireless robots. A 5G data link can offload the computing requirements from these devices to an edge computer, making glasses and robots lighter and more energy efficient.

Figure 3 illustrates an AR device using a 5G private network. A camera integrated into AR glasses takes images and sends them to a processing server that determines the current field of view of the camera and the optimal placement for the augmentations previously registered in the current image. The server renders the augmented image, sending it back to the AR glasses to display. Augmentation in the view needs to closely follow the movement of the AR glasses without introducing distortion. This use case requires significant computational capability, high uplink and downlink data rates and low latency.

Figure 3 AR use case using a 5G private network with edge computing. Source: Korea Electronics Technology Institute.

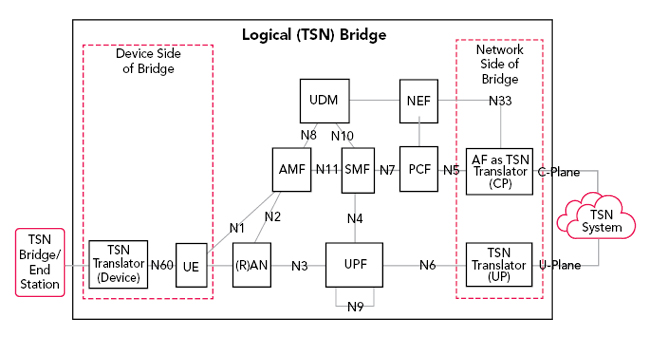

TSN — TSN support is another important 5G feature for private networks, a key enabler for factory automation. The low latency capabilities of 5G can create a time-sensitive communication channel spanning the end-to-end infrastructure. Many private 5G networks will be deployed in existing factories using a wired communication infrastructure that is adopting wired TSN. Translating wired TSN capabilities into 5G, and vice versa, is important and complex, as shown in Figure 4.

Figure 4 5G network with TSN integration.

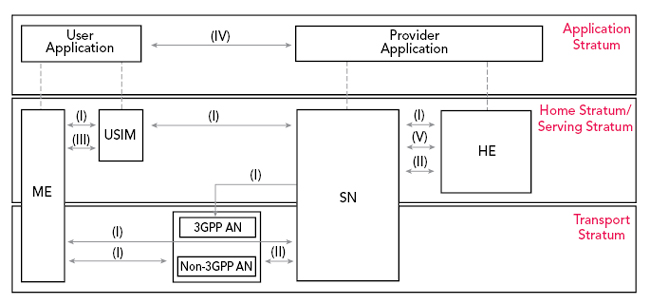

Security — Security is an important aspect of private 5G networks. Compared to previous generations of cellular technology, 5G includes significant security enhancements, including more capable and secure encryption and authentication (see Figure 5). The 5G network architecture is designed to implement the security measures necessary for the different services a network provides, whether a voice call, control of a robot or collecting data from hundreds of sensors.

Figure 5 3GPP 5G security architecture.