The advantages of modern RF/microwave power sensors are highlighted, and applications for sensors with USB and local area network (LAN) interfaces are described.

RF/microwave power sensors are now fully integrated measurement devices, giving today’s engineers many more convenient and direct methods for collecting information, making measurements, sending data and controlling power. USB and LAN interfaces enable power sensors to integrate into many different environments and provide entirely new, flexible ways to measure power, with usage models such as monitoring power at remote locations, fast and simple control with a laptop and creating more compact, automated test racks.

CHOOSING THE TYPE OF POWER SENSOR

Before selecting the best method for control, the correct type of power sensor must be chosen. The most common types are multipath diode, wideband, thermal and average. Each offers unique capabilities, so choosing the “right” one depends on the kind of signals being measured and the desired results.

Multipath Diode Power Sensor

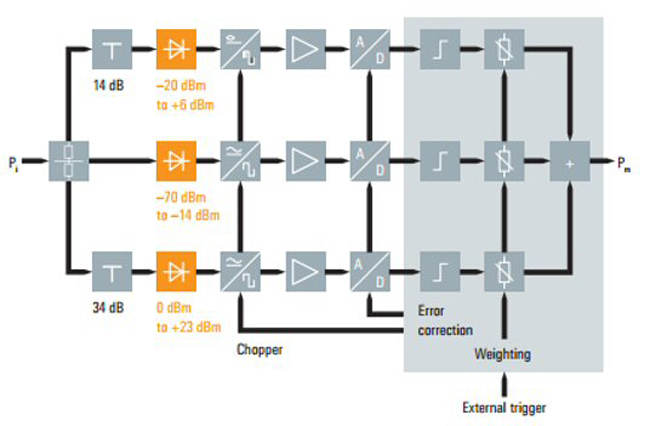

The multipath diode power sensor is the most common and offers the best all-around performance: excellent accuracy, lowest noise floor, largest dynamic range and fastest measurement speed. To achieve the dynamic range, the sensor has multiple paths optimized to measure different ranges of input power (see Figure 1). All paths are continuously and simultaneously measured and, unlike conventional multipath technology, power sensors with adjacent diode paths can overlap by 6 dB. The final measurement result is determined by appropriately weighting the measurements of all paths. These sensors can make several types of measurements, including average power (CW and modulated signals), burst/time slot average and trace.

Figure 1 Multipath diode power sensor.

Wideband Power Sensor

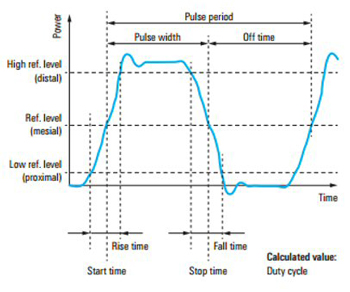

Figure 2 A wideband sensor can measure power levels (a) or power vs. time (b).

The wideband power sensor is predominately used for measuring pulsed signals. Wideband sensors can sample a signal fast enough to analyze pulse profiles, though they are generally not as fast or as accurate as multipath diode sensors. Because of their speed, wideband sensors can measure power level or the power at specific times (see Figure 2).

Thermal and Average Power Sensors

The thermal power sensor uses a thermocouple design and is the most accurate, ideal for applications where accuracy is critical, such as in a calibration lab.

The average power sensor is a multipath diode sensor with reduced measurement capabilities; it only measures average power. A strength of many average power sensors is their wide frequency range, operating down to 8 kHz. Average power sensors are ideal for electromagnetic compatibility (EMC) applications where measuring power to low frequencies is required.

Once the measurement requirements are understood, choosing the correct type of power senor is an easier task. Then, the question is how to operate and control the sensor.

MODERN POWER SENSORS

Classically, the power sensor connected to a device under test and plugged into a power meter, sitting on a bench, with a front panel for push-button control. The power sensor detected the RF/microwave signal, converted or rectified it, then provided the signal to the power meter. The power meter calculated and displayed the measurement results.

By around 15 years ago, the measurement engine was moved from the power meter to the power sensor, making the sensor a complete measurement device. Advancements in microwave technology, as well as more powerful embedded controllers, make the new sensors more accurate, while opening a world of options for control and operation. The power meter box is now used as a host, controlling and displaying the measurement results.