Laser systems specialist LPKF Laser & Electronics, based in Hannover, Germany, has added a foundry service for thin glass substrates to its product portfolio.

The Laser-Induced Deep Etching (LIDE) technology is a process for the precise and highly efficient manufacturing of through-glass vias (TGV) and other deep micro features in thin glass substrates. The LIDE process overcomes limitations in glass drilling and micro machining by combining very high productivity and low manufacturing cost with the superior quality of a direct data process, forgoing masks and photo processing.

The service is aimed at the manufacturing of glass substrates for advanced IC and MEMS packaging, as well as micro-machining spacer wafers, microfluidics and other specialty glass applications.

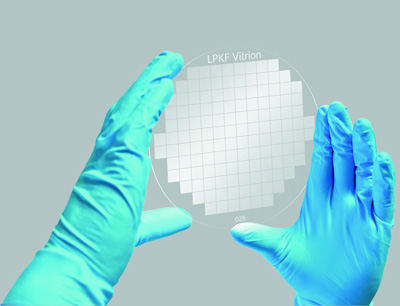

With the introduction of its independent foundry service, LPKF plans to make the LIDE technology available on a much wider scale, covering prototyping and experimental applications as well as offering scalable mass production capacity. LPKF’s new foundry service is located at its corporate headquarters and will operate under the company’s Vitrion brand.