The challenges of microwave verification and manufacturing testing have never been greater, as managers and engineers are continually asked to do more with less. The ever increasing demands of speed to market mean that by the time the test manager receives the test requirements, the program is usually behind schedule. At this point a suitable test solution needs to be selected, acquired and implemented.

This traditional approach to Automatic Test Equipment (ATE) development involves selecting appropriate instruments and then integrating these assets to form a complete test solution for the Device Under Test (DUT). The integration typically involves creation of software to control the test system, environment and possibly the DUT. This effort can take

months of system and software engineering time that the program cannot afford.

The Aeroflex 7700 Integrated Microwave Test Solution addresses this problem by turning the traditional ATE approach upside down. The 7700 is not a single instrument or even a group of instruments; it is a complete test system. Built around a full-featured test executive software called the Aeroflex Measurement Console (AMC), the 7700 contains measurement sequences that control all aspects of the test, including signal generation, measurement, switching, power handling, temperature and DUT control. By accelerating the time between requirements and testing, the 7700 helps put programs back on schedule.

A True Synthetic ATE in a Box

Over the past decade, Aeroflex has been a pioneer in the development of synthetic test systems targeted specifically at reducing the cost of test of complex ATE environments. The 7700 is the next stage of this measurement evolution. By combining modular PXI hardware, the Aeroflex common platform modules, and the AMC test executive, the 7700 provides a capable, flexible and scalable synthetic test instrumentation with the lowest cost of ownership in the industry.

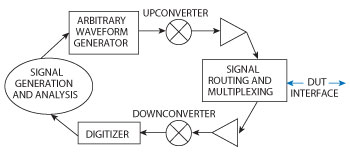

Figure 1 System architecture.

The system utilizes a common set of hardware for stimulus and response functions (see Figure 1). This common utilization reduces hardware costs, results in a smaller footprint than conventional systems and allows for a system-level calibration scheme that provides superior performance as compared to a traditional rack and stack approach. Using the production test sequences in AMC, the 7700 includes the capability to emulate the functionality of the following instrumentation:

- Vector signal generator

- Spectrum analyzer

- Vector network analyzer

- Oscilloscope

- Power meter

- Frequency counter

- Noise figure meter

- Phase noise analyzer

The system can also meet or exceed most standard instruments when it comes to RF performance.

- Frequency Range: 1 MHz to 6 GHz (expandable to 32 GHz)

- RF Modulation BW: 90 MHz

- Frequency Switching Times: < 1 msec

- Output Power Range: > 100 dB

- Phase Noise (2 GHz, 20 kHz offset): −115 dBc/Hz

- Residual Noise Floor: < −120 dBm

- Total Dynamic Range: > 100 dB

- DANL (1 Hz res bandwidth)

- 1 MHz to 1 GHz: −164 dBm/Hz

- 1 to 3 GHz: −159 dBm/Hz

- 3 to 6 GHz: −154 dBm/Hz

Figure 2 The 7700 includes a complete measurement suite that would normally require a full rack of instrumentation.

Figure 2 shows some common measurements controlled by the test executive software AMC. This mature software package provides a complete measurement and development environment, including test execution, sequencing of multiple tests, and reporting of test data as well as test development and debug.

Future Proof Design

The 7700’s true synthetic flexible architecture ensures that today’s system can meet tomorrow’s requirements. With traditional instrumentation, new measurements or increased performance requires the system engineer to replace individual instruments used in the test system. Measurement software developed using these instruments will need to be modified or completely rewritten. It is often more economical to simply replace the entire system rather than upgrade to new capability. With the 7700’s modular synthetic approach, most new measurements require only a new software sequence. When new hardware is needed to meet new requirements, such as higher instantaneous bandwidth, possibly only a single PXI card will need to be replaced. Since the 7700 measurement sequences utilize a synthetic hardware driver layer, none of the existing measurement sequences will be affected with the addition of the new hardware. It is even possible to add hardware to configure the 7700 to cover RF frequencies up to 32 GHz.

Figure 3 The 7700 removes the need to make independent calls to several instruments and the DUT.

World Class Measurement Speed

With traditional instrumentation, system engineers are often forced to develop independent instrument, power, environmental and DUT control schemes. This usually requires additional hardware and software to be added to the system architecture, compromising efficiency and reducing throughput. By providing tight coupling of all test aspects, the 7700 removes the additional software overhead and measurement processing necessary to make independent calls to several instruments and the DUT when executing a test (see Figure 3).

In the 10+ years of delivering similar synthetic solutions, Aeroflex has received customer feedback that this approach has consistently yielded a better than 43improvement in measurement throughput over traditional methods.

Configurations and Measurements for Many Applications

The 7700 is delivered with measurement sequences that provide basic measurement capability including the emulation of signal generators, spectrum analyzers and vector network analyzers. In addition to the basic sequences, comprehensive libraries are available that provide many measurements typically performed during the characterization and test of RF devices. These measurement sequences

provide the ability to generate complex stimulus signals, receive the response signals from the DUT, and process the data to derive the required data product, all while providing tightly synchronized control of the DUT.

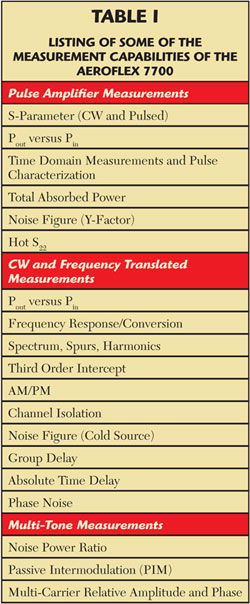

Table 1 shows some of the measurement personalities that are available for the 7700.

The next generation of synthetic-based instrumentation has been developed and released. To date, the 7700 provides the most complete “ATE in a Box” solution.

Aeroflex,

Wichita, KS

(316) 522-4981

www.aeroflex.com

info-test@aeroflex.com