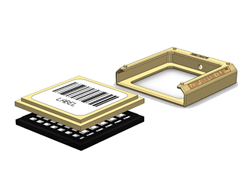

Compound semiconductor die are getting thinner, and standard waffle packs aren’t designed to contain them. The result is die migration, resulting in higher cost from yield loss, rework labor and returned material to suppliers. Gel-Pak® and BAE Systems® designed a new lid clip system that works with standard waffle pack chip trays and eliminates die migration. LCS2 is a patented lid clip system that ensures uniform compression across the lid of the waffle pack, which prevents components from escaping their pockets. Using static dissipative materials to enhance protection from electrostatic discharge, LCS2 ensures valuable devices arrive defect-free and are ready for assembly.

Gel-Pak and BAE Systems designed LCS2 with the goal to prevent die migration by sealing every pocket in a waffle pack. Choosing materials for the lid clip system, they began by selecting a low outgassing, static dissipative, low density polyurethane foam and industry approved interleaf material. These are assembled into a static dissipative, injection molded lid using a silicone-free pressure sensitive adhesive. The patented “gold” lid is combined with a patented, highly engineered “gold” clip design that uniformly compresses the lid onto the tray, ensuring complete contact of the entire interleaf against the surface of the waffle pack tray. The static dissipative material used for the lid and clip was tested per ANSI/ESD S11.11 to ensure ESD Class 000 protection for semiconductor devices with the lowest voltage susceptibility thresholds.

The resulting design keeps thin die in place in the waffle pack, eliminating past defects caused by die migration, either during transport or during assembly. The LCS2 lid clip system improves overall manufacturing yields and reduces the amount of troubleshooting, rework and overage, leading to improved manufacturing cycle time and reduced product cost.

Gel-Pak

Hayward, Calif.

www.gelpak.com/lcs2/