RESULTS

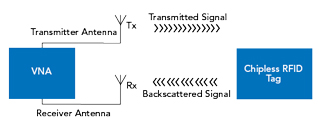

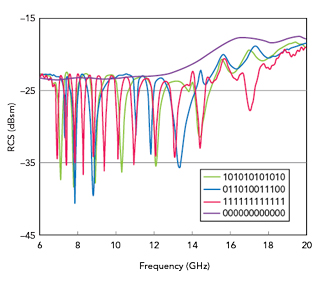

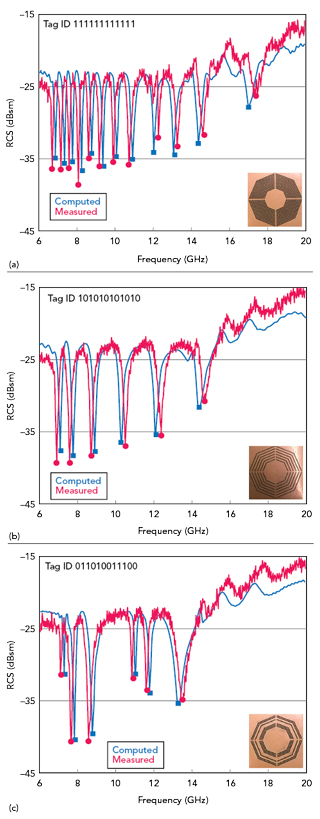

The tag measurement setup comprised a Rohde & Schwarz R&S®ZVB-20 vector network analyzer (VNA), a pair of linearly polarized transmit and receive horn antennas and fabricated prototypes of the tag (see Figure 6).16 A resonant peak at a particular frequency because of the presence of a resonating element is interpreted as a 1, signifying complete absorption; in the case of complete reflection, i.e., no resonating element, a 0 is encoded. Adding and removing resonating elements leads to the formulation of distinct bit combinations (see Figure 7). A graphical comparison of the numerically computed and experimentally measured results shows good agreement. Repeating, alternating and random bit sequences from tags on a 0.508 mm thick Rogers RT/duroid 5880 laminate are shown in Figure 8. Table 2 lists the properties of the laminate. Copper with a thickness of 0.035 mm was used as the radiator. The encoding capacity is determined by the number of resonating slot elements to obtain an equal number of resonances in the resulting frequency band. Figure 5a shows 12 octagonal resonating elements in a cobweb shape, corresponding to the RCS response in Figure 8a for a sequence of all 1s. Each cobweb shaped resonator represents a bit, resulting in a total capacity of 12 bits. Within the operating band from 6.5 to 18 GHz, there are 12 resonances with a 1:1 resonance-to-slot correspondence. The examples shown in Figure 8 illustrate the capability of the design to encode any 12-bit sequence. The RFID tag has a small 5.29 cm2 footprint, achieving a bit density of 2.26 bits/cm2. It is insensitive to a variety of polarization angles and is viable for use on non-rigid substrates.

Figure 6 RFID tag measurement setup.

Figure 7 RCS responses for various bit sequences created by adding or removing resonating elements.

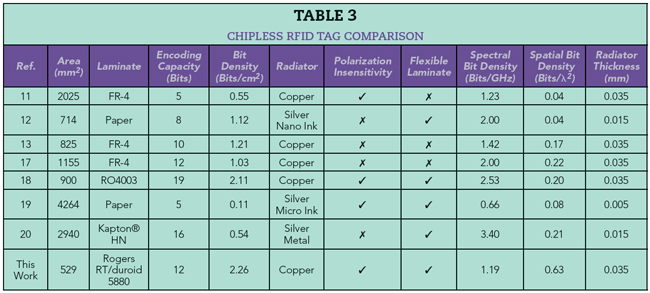

A comprehensive comparison of this work with other reported results is summarized in Table 3. The table includes encoding capacity, bit density, polarization insensitivity, the flexible nature of the laminate, spectral bit capacity and spatial bit density. Encoding capacity is the number of bits stored for encoding data, which is 12 in this design. Bit density is the number of bits per unit area, usually measured in bits/cm2. The readability of the tag at different orientations with reference to the XY plane is indicated by polarization insensitivity. Spectral bit density is the number of bits per GHz, and spatial bit density relates to the number of bits per λ2, where λ is the wavelength.

Figure 8 Computed vs. measured RCS responses for tags with repeating (a), alternating (b) and random (c) bit sequences.

CONCLUSION

A passive, polarization independent, chipless RFID tag with a compact size of 23 × 23 mm and 12-bit encoding capacity provides a bit density of 2.26 bit/cm2. The design mitigates high order harmonic components and possesses 1:1 slot-to-bit correspondence, enabling a total of 4096 items to be uniquely tagged.

Acknowledgments

This work was financially supported by Vinnova, the Swedish Governmental Agency for Innovation Systems, and the University of Engineering and Technology in Taxila, Pakistan, through the Vinn Excellence Centers program and ACTSENA research group funding, respectively.

References

- G. Roussos, S.S. Duri and C.W. Thompson, “RFID Meets the Internet,” IEEE Internet Computing, Vol. 13, No. 1, March 2009, pp. 11–13.

- M.M. Khan, F.A. Tahir, M.F. Farooqui, A. Shamim and H.M. Cheema, “3.56-bits/cm2 Compact Inkjet Printed and Application Specific Chipless RFID Tag,” IEEE Antennas and Wireless Propagation Letters, Vol. 15, No. 1, January 2015, pp. 1109–1112.

- R.A.A. Rodrigues, E.C. Gurjão, F.M. de Assis, V. Palazzi, F. Alimenti, L. Roselli, P. Mezzanotte and S. Tedjini “Design of Planar Resonators on Flexible Substrate for Chipless Tags Intended for Crack Sensing,” IEEE 15th Mediterranean Microwave Symposium, November-December 2015.

- S. Preradovic and N.C. Karmakar, “Chipless RFID: Barcode of the Future,” IEEE Microwave Magazine, Vol. 61, No. 7, December 2010, pp. 87–97.

- S. Dey and N.C. Karmakar, “Towards an Inexpensive Paper Based Flexible Chipless RFID Tag with Increased Data Capacity,” International Conference on Sensing Technology, December 2017.

- U.H. Khan, B. Aslam, M.A. Azam, Y. Amin and H. Tenhunen, “Compact RFID Enabled Moisture Sensor,” Radioengineering, Vol. 25, No. 3, September 2016, pp. 449–456.

- C. He, Z.J. Wang and V.C. Leung, “Unitary Query for the M × L × N MIMO Backscatter RFID Channel,” IEEE Transactions on Wireless Communications, Vol. 14, No. 5, April 2014, pp. 2613–2625.

- A. Toccafondi, C. Della Giovampaola, F. Mariottini and A. Cucini, “UHF-HF RFID Integrated Tag for Moving Vehicle Identification,” IEEE Antennas and Propagation Society International Symposium, June 2009.

- M.W. Gallagher and D.C. Malocha, “Mixed Orthogonal Frequency Coded SAW RFID Tags,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, Vol. 60, No. 3, March 2013, pp. 596–602.

- B. Aslam, U.H. Khan, A. Habib, Y. Amin and H. Tenhunen, “Frequency Signature Chipless RFID Tag with Enhanced Data Capacity,” IEICE Electronics Express, Vol. 12, No. 17, September 2015.

- F. Costa, S. Genovesi and A. Monorchio, “A Chipless RFID Based on Multiresonant High-Impedance Surfaces,” IEEE Transactions on Microwave Theory and Techniques, Vol. 61, No. 1, January 2013, pp.146–153.

- A. Habib, R. Asif, M. Fawwad, Y. Amin, J. Loo and H. Tenhunen, “Directly Printable Compact Chipless RFID Tag for Humidity Sensing,” IEICE Electronics Express, Vol. 12, 2017, pp. 236–242.

- S. Rauf, M.A. Riaz, H, Shahid, S. Iqbal, Y. Amin and H. Tenhunen, “Triangular Loop Resonator Based Compact Chipless RFID tag,” IEICE Electronics Express, Vol. 14, No. 10, April 2017.

- C.M. Nijas, U. Deepak, P.V. Vinesh, R. Sujith, S. Mridula, K. Vasudevan and P. Mohanan, “Low-Cost Multiple-Bit Encoded Chipless RFID Tag Using Stepped Impedance Resonator,” IEEE Transactions on Antennas and Propagation, Vol. 62, No. 9, September 2014, pp. 4762–4770.

- A. Lazaro, A. Ramos, X. Girbau and R. Villarino, “A Novel UWB RFID Tag Using Active Frequency Selective Surface,” IEEE Transactions on Antennas and Propagation, Vol. 61, No. 3, March 2013, pp. 1155–1165.

- A. Vena, E. Perret and S. Tedjini, “Chipless RFID Tag Using Hybrid Coding Technique,” IEEE Transactions on Microwave Theory and Techniques, Vol. 59, No. 12, December 2011, pp. 1155–1165.

- L. Xu and K. Huang, “Design of Compact Trapezoidal Bow-Tie Chipless RFID Tag,” International Journal of Antennas and Propagation, 2015.

- A. Vena, E. Perret and S. Tedjini, “High-Capacity Chipless RFID Tag Insensitive to the Polarization,” IEEE Transactions on Antennas and Propagation, Vol. 60, No. 10, October 2012, pp. 4509–4515.

- D. Betancourt, K. Haase, A. Hübler and F. Ellinger, “Bending and Folding Effect Study of Flexible Fully Printed and Late-Stage Codified Octagonal Chipless RFID Tags,” IEEE Transactions on Antennas and Propagation, Vol. 64, No. 7, July 2016, pp. 2815–2823.

- A. Habib, S. Ansar, M.A. Azam, Y. Amin and H. Tenhunen, “Directly Printable Organic ASK Based Chipless RFID Tag for IoT Applications,” Radioengineering, Vol. 26, No. 1, April 2017.