The fourth industrial revolution (Industry 4.0) triggered by industrial IoT (IIoT) will offer significant revenue expansion through new digital service provider markets. The main technology enablers for the IIoT revolution will comprise of 1.) 5G wireless converged automation protocols which will eliminate wires and support time synchronous operations, 2.) private edge cloud for secure and scalable local computing, 3.) deep slicing for IIoT networks so that multiple stakeholders can be supported using one infrastructure and 4.) machine learning (ML) enabled automated operations for monitoring, prediction and optimization of IIoT networks. Further, the IIoT network will be scalable in connectivity and number of devices and will be designed to deliver optimal performance for all industrial applications using key LTE and 5G New Radio (NR) features like ultra-reliable low-latency communication (URLLC), massive machine type communication (mMTC), 5G positioning, time sensitive communications (TSC) and, to a lesser degree, enhanced mobile broadband (eMBB).

In this article, we will begin with overview, use cases and requirements for IIoT. Next, we will discuss the foundation for URLLC in NR which was laid out in 3GPP Rel-15, mainly in support of IIoT. We then will address several IIoT related features in Rel-16 like URLLC enhancements, NR positioning and TSC and a version of NR known as NR-Light, which is planned to be introduced in Rel-17. NR-Light aims to address use cases that cannot be met by NR eMBB, URLLC or mMTC. Finally, we will present system performance for an indoor ray traced factory using key 5G NR features like URLLC and TSC.

IIoT powered by 5G networks will enable new value creation and offer significant revenue expansion for original equipment manufacturers (OEM) and network operators. IIoT will offer increased efficiency with industrial automation on a shared highly flexible virtualized and scalable infrastructure. It will be driven by key 5G NR features like URLLC, 5G positioning, TSC and, to a lesser degree, eMBB. IIoT will also be complemented by MTC technologies developed for LTE and known as enhanced MTC (eMTC) and narrowband IoT (NB-IoT). The foundation for URLLC was laid out in Rel-15 3GPP specifications. IIoT networks will be further enhanced by subsequent releases of 3GPP specifications (Rel-16 and Rel-17) with new features as outlined here.1-2

IIoT Use Cases and Requirements

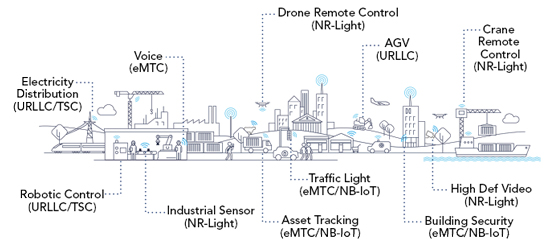

A pictorial representation of Industry 4.0 use cases with the corresponding 5G technology features is shown in Figure 1. The two major Industry 4.0 verticals are manufacturing and transport/logistics industry. For the factory of the future, productivity must be improved while also improving safety and cost efficiency. Processes must be automated, and production uptime maximized to minimize business interruption to gain more efficiency and competitiveness and value for investments. At the same time, carbon emissions need to be reduced and energy be saved. To satisfy the above goals, one will see mass personalization of products, artificial intelligence (AI) backed automated testing, monitoring and analytics for production resiliency and digital value platforms for fast re-configuration of supply chains. The goal of the future transport/logistics industry is to increase throughput using existing infrastructure, eliminate consignment losses and transit time delays and ensure resiliency of IT infrastructure and control systems. To that end, transportation/logistics industry will see massive use of AI managed automated guided vehicles (AGV) for maximum throughput, resilient and secure control systems and massive instrumentation to ensure minimal carbon footprint.

Figure 1 Industry 4.0 use cases and corresponding 5G NR features.

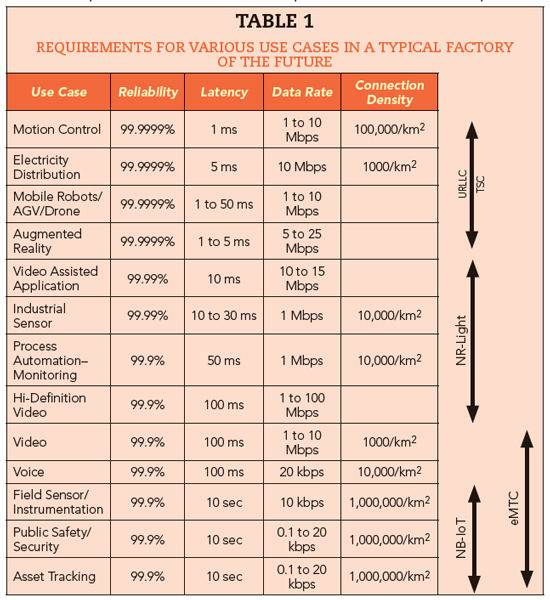

5G NR enables new value creation for Industry 4.0 based on three major use case domains, namely eMBB, URLLC and mMTC. Table 1 shows the requirements in terms of reliability, latency, data rate and connection density for a typical factory complex. Additionally, it shows the various 5G component technologies needed to meet the requirements for the use cases.

The beginning of Industry 4.0 is being showcased in Nokia’s 5G “factory of the future” in Oulu, Finland.3 This pre-production facility uses Nokia’s private wireless networks and edge cloud to securely connect all assets within and outside the factory.

Foundation for URLLC

Two key requirements were defined by 3GPP for URLLC use cases:4 1.) target user plane latency of 0.5 ms in the downlink and 0.5 ms in the uplink and 2.) packet reliability of 99.999 percent for a 32-byte packet with a user plane latency of 1 ms. The coupling of very high-reliability together with very low-latency makes URLLC requirements very challenging to satisfy. However, as noted in Table 1, many IIoT use cases do not require both ultra-reliability and low latency. To this end, 3GPP Rel-15 has separately specified two physical layer (PHY) feature groups to support URLLC.

The first group of PHY features are used to reduce latency. They include:

Flexible slot structure:

- Support of multiple subcarrier spacing values - NR supports subcarrier spacing of 15, 30, 60, 120 and 240 kHz. This translates into transmission slot length of 1, 0.5, 0.25, 0.125 and 0.0625 ms, respectively. Having a shorter slot length helps reduce latency as the data transmission process can be completed sooner. The disadvantage is that a less amount of data can be transmitted per slot. However, this is not crucial as URLLC data packets are typically small compared to e.g., eMBB.

- Sub-slot data transmission - NR allows data transmission that occupies less than a slot (i.e., 2, 4, 7 symbols in downlink, and any number of symbols in uplink). This allows data transmission to be completed in less time. For instance, with a subcarrier spacing of 60 kHz and 2 symbols, a packet can be transmitted in 0.036 ms.

- Self-contained slot structure in TDD - NR allows a slot in TDD to contain symbols for both data and hybrid automatic repeat request (HARQ) acknowledgment feedback. This reduces the wait time in TDD for uplink and downlink slots.

Flexible scheduling:

- Preemption - The base station can pre-empt on-going downlink data transmission to insert URLLC data into the data packet being transmitted. This is done by puncturing the on-going data transmission with URLLC traffic. The pre-empted UE is then notified of the pre-emption so it can appropriately manage the missing data.

- Configured grant or grant-free uplink transmission - User equipment (UE) are configured with periodic resources for uplink transmission. As a result, the UE does not have to transmit a scheduling request to the gNB (i.e., 5G NR base station) and wait for a scheduling grant whenever it has pending data.

Fast feedback:

- Shorter UE processing time - The NR slot structure design allows for UE pipelining to shorten the UE processing time.

- Short HARQ feedback format - A UE can transmit HARQ feedback in one or two symbols.

- Short periodicity for scheduling request - A UE can be configured with a scheduling request slot to request uplink data transmission as often as every 2 symbols.

The second group of PHY features are used to increase reliability. They include:

Data enhancements:

- Transmission of the same data packet from different transmission points to increase reliability. This is supported by duplicating the data packet at the packet data convergence protocol layer. It can be used, for example, to transmit the same packets from two different gNBs to the UE to increase reliability.

- Multi-slot repetition for data channels - Data packet can be transmitted using 2, 4 and 8 repetitions to improve reliability.

- URLLC-specific modulation and coding values that are designed to support very high-reliability.

Control enhancements:

- Support lower coding rate for the associated control channel and smaller control packet size.

- Enhanced channel state information reporting targeting 99.999 percent reliability.

In addition to the physical layer enhancements, URLLC also requires optimized system architecture design. Two important features are:

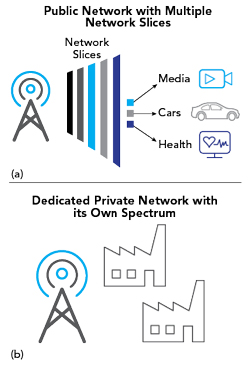

Figure 2 Two options for industrial networks.

- Edge cloud and multi-access edge computing (MEC) - Instead of a centralized architecture, an edge cloud places computing resources at the edge of the network. This allows for reduced end-to-end latency and ultra-fast response time. In addition, MEC is crucial to many IIoT verticals as it allows real-time data analytics and reduces the amount of data that must be sent upstream.

- Network slicing allows for a dedicated set of end-to-end resources to be allocated for multiple applications. For industrial networks, one option is to have public networks with slicing where each slice has guaranteed QoS and security level. The other option is to have a dedicated private network with its own “local spectrum” and customized security and QoS levels. These two options are illustrated in Figure 2.