The MA24507A Power Master™ frequency selectable millimeter wave (mmWave) power analyzer from Anritsu is the world’s first frequency selectable RF power sensor. By utilizing Anritsu’s patented Shockline nonlinear transmission line (NLTL) technology, Power Master combines the industry’s widest power measurement range, fast measurement speeds and the ability for the user to define the frequency of the signal to measure—all with the convenience of a USB-powered instrument. With measurement capability to 70 GHz, the MA24507A opens up new test capabilities for growing mmWave applications, like 802.11ad, WirelessHD™ and 5G wireless backhaul.

THE SHOCKLINE ADVANTAGE

Anritsu’s state-of-the-art Shockline-based receiver uses a patented NLTL technique to sample RF signals. This gives Anritsu instruments the ability to sample high frequency signals that would normally require expensive fundamental mixers or leaky step recovery diode samplers. NLTL technology has made Anritsu the leader in high frequency VNAs, with products like VectorStar® and ShockLine™ VNAs. With Power Master, NLTL enables accurate measurement of mmWave power in an instrument just slightly bigger than a smartphone.

Anritsu’s Shockline receiver has a dynamic range greater than 100 dB at all frequencies. Most power sensors use a diode or thermal-based element to detect changes in RF power. While these methods provide highly accurate power readings, they have limited power measurement range. Diode sensors typically do not measure signals below -60 dBm; even at that level, they require high measurement averaging to provide stable readings. Thermal sensors are even worse, generally tapping out around -30 dBm. Using the Shockline receiver to detect power, Power Master accurately reads many signals as low as -100 dBm. This is especially advantageous for over-the-air (OTA) testing of mmWave signals, which suffer high propagation losses through the air. Many mmWave receivers, like 802.11ad access points and automotive radar, may see signals below -90 dBm. With Power Master, users can read signals at those levels necessary for important tests like calibrating mmWave systems at both the transmitter and receiver, or measuring signal strength across various distances and through objects. This measurement flexibility creates a more robust test system by expanding the number of verification tests, which results in better designs and more reliable products.

COMPELLING FEATURES

PowerMaster allows the user to define the frequency band for measuring power. Thermal and diode-based sensors are inherently broadband, meaning they aggregate the power of all signals—regardless of the frequency—while making a measurement. That is not a concern for many controlled applications; however, in the field or when troubleshooting in the lab, it can hinder characterizing system behavior correctly. For example, when field testing signal strength for wireless backhaul networks, a diode or thermal power sensor will not differentiate between the intended RF signal from the other signals within the sensor’s frequency range, which may make the measurement useless. With Power Master, a field technician can define the frequency channel in which to measure power, focusing on the signals of interest or identifying specific interference in nearby channels. In the lab, an engineer verifying RF circuit designs can use Power Master for troubleshooting unexpected signal behavior caused by a dirty LO, bad components or outside signal interference.

Perhaps the most amazing benefit of the Shockline technology is its ability to fit all these features into a portable, USB-powered instrument that is convenient to use in the lab or field. Power Master is only slightly bigger than a smartphone, at approximately 6"× 3"× 1"and weighs less than 15 oz. For field testing, it is equipped with a standard ¼"mounting port that is compatible with a variety of extenders, perfect for raising the sensor close to access points or above crowds. In the lab or EMI chamber, it can connect the sensor to a tripod to position it for OTA testing. The sensor is also equipped with mounting holes for on-wafer testing. Instead of purchasing expensive low loss cables to connect to the power meter, Power Master connects directly to a probe, improving measurement accuracy and reliability.

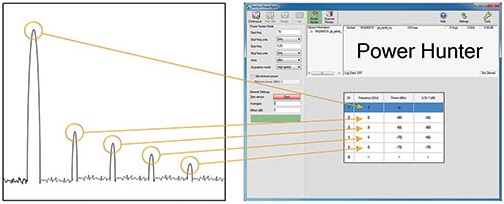

Figure 1 The PowerXpert PC application enables users to search for CW peaks within any defined frequency channel up to 70 GHz.

Power Master comes with the standard benefits of a USB power meter. Because no reference calibration is required, the sensor can stay connected to a test system at all times, eliminating the need to disconnect and reconnect the sensor between test procedures. The sensor can be controlled by remote commands via the USB interface or through PowerXpert™, Anritsu’s free PC application for USB power measurement tools.

PowerXpert has been updated with new features to search for up to six power peaks across user-defined frequency bands or simultaneously monitor the RF power of up to six separate frequency channels (see Figure 1).

Whether in the lab or the field, Power Master provides revolutionary power measurement capabilities. With the industry’s best low power performance, frequency selectability and the convenience of a USB-powered instrument, Power Master is a “must have” for anyone testing WiGig, WirelessHD, auto radar or other mmWave applications.