In addition to the vast array of consumer electronics, wireless infrastructure, military and space-based communication applications that are enabled by microwave technology, RF waves are also used to heat dissipative objects and power physicochemical processes. One example is, of course, the microwave ovens ubiquitous in our residential and commercial kitchens. Another would be microwave-based dryers used for industrial tasks like drying or curing fruit or meat.

The “heating” market is where some of the most exciting new uses for microwave energy are emerging. Here, RF energy generated by solid-state semiconductor chains – rather than the traditional, inefficient, short-lived magnetrons – is being contained, controlled and directed with more precision than before, yielding a host of new uses for RF energy:

- Efficiently jumpstarting automotive ignition and industrial lighting systems

- Enabling more precise medical imaging and analysis (MRI and NMR equipment)

- Empowering a new generation of “smart,” solid-state microwave ovens that are highly programmable, IoT-connected and able to distinguish among the components of your meal.

Figure 1 Measured insertion loss and isolation of the 600 and 300 W 3 dB couplers.

While several market-making suppliers, many of whom are founders of the RF Energy Alliance, have launched (or have in their near-term pipelines) many of the technologies needed to realize this potential, passive RF components have not kept pace with the power handling and performance requirements for these new applications. Until now.

A Better Fit All Around

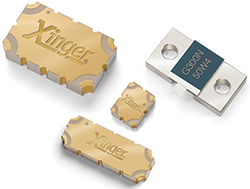

Operating in the 2.4 to 2.5 GHz ISM band, a new family of passive RF components specifically designed for these high energy applications is now available from Anaren. The family currently comprises two Xinger®-brand 3 dB hybrid couplers (XEC24E3-03G and XEC24A6-03G),one Xinger 30 dB directional coupler (XEC24P3-30G) and a flanged, AlN termination (G300N50W4) optimized to work with the couplers. The new products offer excellent electrical and dimensional characteristics when compared to competitive discrete and PCB-printed solutions.

Measuring 0.560" × 0.350" (14.22 × 8.89 mm), the XEC24A6-03G is a low profile, high performance 3 dB hybrid coupler in an industry exclusive (patent pending) ceramic/soft board SMT package suitable for applications up to 600 W. The coupler has a maximum insertion loss of 0.15 dB, minimum isolation of 20 dB and an amplitude balance of ±0.3 dB maximum (see Figure 1). It is available in a 6 of 6 ENIG RoHS-compliant finish. Handling up to 300 W, the XEC24E3-03G 3 dB hybrid is in a low profile SMT package measuring 0.560" × 0.200" (14.22 × 5.08 mm), also with a RoHS compliant ENIG finish. This hybrid has 0.15 dB maximum insertion loss, 23 dB minimum isolation and an amplitude balance of ±0.25 dB maximum (also shown in Figure 1).

Figure 2 Measured coupling, insertion loss and directivity of the 30 dB directional coupler.

The XEC24P3-30G directional coupler measures 0.250" × 0.200" (6.35 × 5.08 mm), operates up to 300 W, has a maximum insertion loss of 0.1 dB, tight coupling of 30 ±1.0 dB, high directivity of 20 dB minimum and frequency sensitivity of 0.25 dB maximum (see Figure 2).

Designed to match and complement the couplers, the G300N50W4 is a high performance AlN flange mount termination with performance specifically tuned for the 2.4 to 2.5 GHz ISM band and intended for use in RF heating applications. Handling 300 Waverage input power, the RoHS compliant termination has a nominal impedance of 50 Ohms with a minimum return loss of 25 dB (see Figure 3). It measures 0.975" × 0.500" (24.77 × 12.7 mm).

Of particular advantage to designers of high power and, thus, high heat-generating applications, the two high power 3 dB hybrids and the directional coupler in this family are manufactured using materials with coefficients of thermal expansion (CTE) that are compatible with common substrates such as FR-4, RF-35 and RO4350. In high power applications, where temperature variations can be extreme, the result of this material choice is a more durable and reliable physical connection between the component and the PCB during repeated, highly varied cooling and heating cycles. The operating temperature range for the 3 dB hybrids and directional coupler is -55° to +95°C, and the termination is designed to operate to +150°C.

Figure 3 Measured return loss of the termination.

Anaren’s unique combination of heat-dissipating materials and the stripline construction used with this product family also allows for considerable space savings compared to traditional, connectorized high power couplers. This size advantage is most evident with the 600 W XEC24A6-03G hybrid: the 0.560” × 0.350” package is a fraction of the size of other couplers on the market, where footprints of 3" × 1" or larger are not unusual. The patent-pending technology used in this hybrid makes it an option for other applications and markets where high power handling or just high power density is needed.

Anaren Inc.

Syracuse, N.Y.

www.anaren.com

sales@anaren.com