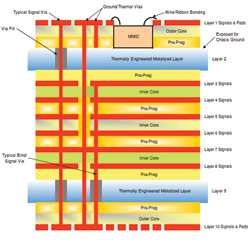

Cirexx has developed the ECLIPS™ PCB systems based on a Lockheed Martin patented and licensed technology. ECLIPS (Embedded Cooling Layer Interactive Power System) is an advanced PCB system employing a specially developed, thermally engineered, metalized copper graphite composite with a ceramic-matched CTE. The engineered material has superior thermal conductivity properties and CTE values matched with Si, SiC, GaAs and GaN. This provides a reduced overall PCB weight, higher power density and heat dissipation capabilities while maintaining the PCB structure in a stable form for direct die-attach of advanced components, such as GaA and GaN. Due to the stability and construction of the ECLIP PCB, all supporting components are standard SMT plastic packages. This can significantly reduce the cost of advanced designs by allowing for standard SMT assembly and eliminating ceramic die component sourcing, procurement and assembly of non-essential parts.

Cirexx has developed the ECLIPS manufacturing technique and process to incorporate this material into a standard PCB structure.

Common PTFE laminates can be selected to support advanced signal integrity along with variable thickness dielectrics. Heavy copper core layers for additional power and ground use are also available. The thermally engineered composite is currently stocked in 10, 20 and 40 mil thickness for use in PCB structures as a heat sink and stabilizer. Cirexx will help customers design an ECLIPS PCB to solve their high power packaging challenges.

CIREXX International

Santa Clara, Calif.

(800) 444-6817

www.cirexx.com