Testing COTS Parts Using Traditional Reliability Standards

In the NESC study, NASA made it clear that manufacturers of COTS parts can perform testing using established standards as they see fit, and the part will still be considered a COTS part if that testing and screening is the choice of the manufacturer. For example, the manufacturer may choose to test parts to demonstrate reliability using the well-known AEC-Q200 Stress Test Qualification for Passive Components standard, or a manufacturer may choose to include MIL-SPEC tests as part of the part number. From NASA’s perspective, if the manufacturer chooses to perform these tests and provide the data, it counts as a COTS part.

WHEN AND HOW TO USE COTS PARTS

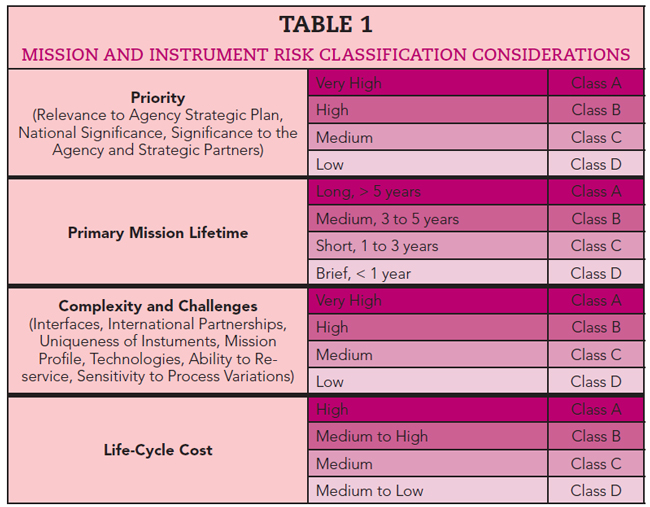

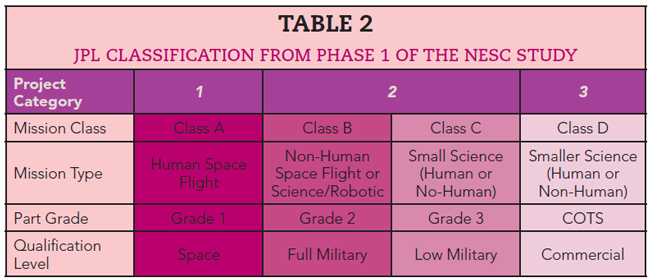

Phase 1 of the NESC report also provides guidance on deciding when and how to use COTS parts. First, the report shows how NASA has traditionally defined how to make this decision based on mission and instrumentation risk (see Table 1). The NESC study then maps this traditional risk class chart to mission types and part grades that one would find in the EEE-INST-002 standard (see Table 2). Defined this way, Class D missions, which include systems such as CubeSats (a type of SmallSat) or the experimental payloads on the International Space Station, are good candidates for including COTS parts.

In addition to understanding the risk classification of a system, the NESC study recommends selecting parts based on the project’s mission, environment, application and lifetime (MEAL) requirements. More specifically, this means considering the following for each aspect:

- Mission – Risk classification, risk posture, schedule, cost and parts requirements

- Environment – Radiation, thermal, vacuum, etc.

- Application – Fault tolerance, architecture, size, weight and power, performance, etc.

- Lifetime – Mission lifespan and system operating conditions during the mission.

NASA’S RECOMMENDATIONS FOR USING COTS PARTS

Overall, in Phase 1 of the NESC study report, NASA conveys there are many suitable applications, such as LEO satcom devices, that could benefit from the reduced costs of using COTS parts.

To successfully determine the COTS parts that will meet a system’s MEAL requirements, NASA recommends establishing a good relationship with an industry-leading parts manufacturer (ILPM). An ILPM is defined by NASA as a COTS parts manufacturer that produces high-quality and reliable parts that do not require additional screening and lot conformance testing. It is important to note there is no official list of ILPMs, and each organization using COTS parts needs to define acceptable ILPMs.

When possible, NASA recommends establishing a relationship with a company that has flight heritage. Additionally, talk with potential suppliers to ensure they respect the part’s datasheet and do not screen parts outside datasheet levels, as this can actually reduce reliability.

USE COTS PARTS ALREADY TESTED FOR RELIABILITY

COTS parts can include consumer, industrial, commercial hi-rel, manufacturer hi-rel and industry hi-rel parts. As noted, when testing, manufacturers have the option to define hi-rel parts using established methods, such as those defined in AEC-Q200 or MIL-SPECS. However, as an end user of COTS parts, it is important to be aware that, depending on the MEAL requirements of an application, an AEC-Q200-qualified part may not cover all the reliability requirements for the mission. Instead of solely looking for parts that are AEC-Q200-qualified or tested to certain MIL-SPECs, it is best to work with an ILPM to understand where potential gaps may exist between the MEAL requirements and the AEC-Q200 qualifications or MIL-SPEC testing.

For example, in 2018, The Aerospace Corporation presented a discussion on the differences between AEC-Q200 parts and MIL-SPEC parts in its “Guide to Using Automotive-Grade EEE Parts in Space Applications.”4 The report shows a comparison between MIL-PRF-123 and AEC-Q200 for capacitors and highlights the following tests that should be discussed with the manufacturer: radiographic inspection, thermal shock, voltage conditioning, terminal strength and life test. In general, this is a good example of the types of test topics that should be discussed with an ILPM during parts selection.

WHAT IS NEXT FOR COTS PARTS IN SPACE?

Even with the recommendations provided in Part 1 of the NESC study, there is not a one-size-fits-all approach to selecting COTS parts for space applications. A good start to determining what could work best for an application is to understand some of the more traditional qualification and screening requirements, such as those defined in the white paper “Ready for Launch: Understanding the Nuances of Space-Level Qualification and Screening of Filters.”5 Then, develop relationships with ILPMs to work together, discuss the project’s MEAL requirements and determine how to effectively select proven and reliable COTS parts for the space application.

NASA will release Phase 2 of the NESC study later this year, providing information to dispell myths about using COTS parts and NASA’s recommendations for new approaches for reliably using COTS parts from ILPMs.

References

- R. F. Hodson et al., “Recommendations on Use of Commercial-Off-The-Shelf (COTS) Electrical, Electronic, and Electromechanical (EEE) Parts for NASA Missions,” December 2020, Web: ntrs.nasa.gov/api/citations/20205011579/downloads/20205011579.pdf.

- J. Leitner, “Phasing in COTS Electrical, Electronic, and Electromechanical (EEE) parts in NASA,” May 2022, Web: www.nasa.gov/smallsat-institute/phasing-in-cots-eee-parts-in-nasa.

- K. Sahu, “EEE-INST-002: Instructions for EEE Parts Selection, Screening, Qualification, and Derating,” April 2008, Web: nepp.nasa.gov/docuploads/FFB52B88-36AE-4378-A05B2C084B5EE2CC/EEE-INST-002_add1.pdf.

- S. Hong and A. Yarbrough, “Guide to Using Automotive Grade EEEE Parts in Space Applications,” June 2018, Web: //nepp.nasa.gov/workshops/etw2018/talks/20JUNE18/1345%20-%20Sung%20Hong%20-%20AEC%20vs%20MIL%20PRF%20NEPP%20Talk%202018.pdf.

- Knowles Precision Devices, “Ready for Launch: Understanding the Nuances of Space-Level Qualification and Screening of Filters,” Web: info.knowlescapacitors.com/white-paper/space-level-qualification-and-screening-of-filters.