Recognizing the growing need for higher frequency, smaller packaging and improved efficiency, MECA Electronics (Microwave Equipment & Components of America) has extended its family of high-quality components to serve mmWave applications. MECA’s portfolio comprises power dividers, couplers, attenuators, terminations, bias tees, DC blocks, isolators and circulators and is available in a variety of connector styles and interfaces, including SMA, N, BNC, TNC, 7/16, 4.1/9.5, 4.3/10.0, 2.92 and 2.4 mm, offering up to 50 GHz coverage with the 2.92 and 2.4 mm connectors.

mmWAVE EXAMPLES

Three examples of 6 to 40 GHz products for VSAT, SATCOM and 5G applications are:

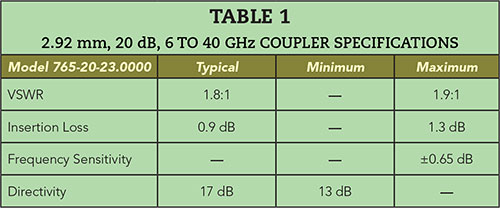

- Model 765-20-23.0000 coupler, with 2.92 mm connectors, has a maximum insertion loss of 1.3 dB, frequency sensitivity of ±0.65 dB and minimum directivity of 13 dB (see Table 1).

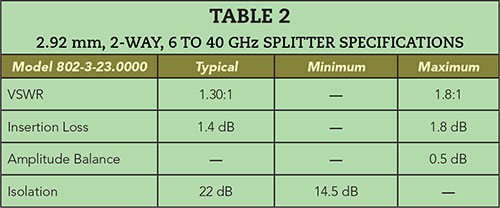

- Model 802-3-23.0000 2-way power divider, with 2.92 mm connectors, has a maximum insertion loss of 1.8 dB, amplitude balance of 0.5 dB and minimum isolation of 14.5 dB (see Table 2).

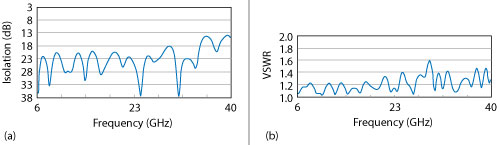

- Model 804-3-23.000 4-way power divider, with 2.4 mm connectors, has a maximum insertion loss of 2.8 dB, amplitude balance of 1 dB and minimum isolation of 13 dB (see Figure 1).

Figure 1 Isolation (a) and VSWR (b) of MECA 804-3-23.000 4-way power divider.

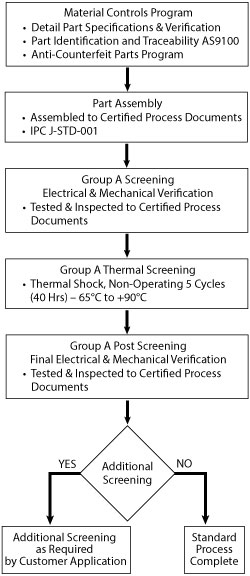

Figure 2 ML screening flow.

These products are supplemented with complementary components such as attenuators, terminations, bias tees, DC blocks and adapters.

AFFORDABLE HI-REL

MECA’s ML series of components are designed for the aerospace and defense industry. The cost-effective series, which includes power dividers, combiners, couplers and terminations, consists of commercial off-the-shelf standard products screened to predefined tests, in accordance with MIL-DTL-23971, MIL-DTL-39030E, MIL-DTL-15370 and MIL-STD-202. The models are designed for precision electrical performance, high-reliability and intended for use in harsh environments, from high altitude defense to low orbit space and satellite applications.

These models undergo MECA’s ML screening process, which incorporates a level of thermal screening combined with verification of electrical and mechanical performance (see Figure 2). Octave and multi-octave products with SMA connectors are built by assemblers and technicians certified to IPC J-STD-001. The ML process provides an economical level of screening for MECA’s standard products, combining best practices for reliability and screening at a reasonable cost, to address the needs of the aerospace industry. To request ML screening, add the ML prefix to any 80X series power divider/combiner, 750, 765, 780 or 785 series coupler or any eligible 40X series termination. If required, enhanced screening for qualification or verification is available.

For high-reliability in harsh environments, MECA’s stripline products include the option of increasing reliability by incorporating a proprietary bonding film process that renders the products impervious to (hazardous) fluids. The process also protects against high humidity and salt fog environments. The bonding film process minimizes the space needed to accomplish this level of reliability, which provides the added benefit of weight reduction. Available screened to custom requirements, these products are also subjected to MECA’s standard screening process for added reliability.

While designed for the space and defense applications, the capability for extended use in harsh environments makes the ML series well-suited for outdoor public safety, commercial wireless, rail, other transportation and field VSAT installations.

A leader in RF components and manufacturing for over 56 years, MECA Electronics has served the RF/microwave industry with equipment and passive components operating to 50 GHz, featuring products manufactured in the U.S. and backed with a 36 month warranty. With expertise in both the commercial and military arenas, MECA is uniquely positioned to offer customers a cost-effective, “in between” solution to meet today’s challenging and changing requirements.

MECA Electronics

Denville, N.J.

www.e-meca.com