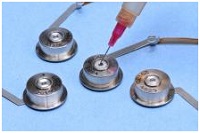

Featuring a low viscosity, EP38CL is an optically clear two component epoxy that is used for bonding, sealing, coating and encapsulation in optical, aerospace, opto-electronic and specialty OEM applications. It possesses superior impact resistance, thermal cycling capabilities as well as the ability to withstand mechanical shock better than typical epoxies that are higher on the Shore D scale.

Featuring a low viscosity, EP38CL is an optically clear two component epoxy that is used for bonding, sealing, coating and encapsulation in optical, aerospace, opto-electronic and specialty OEM applications. It possesses superior impact resistance, thermal cycling capabilities as well as the ability to withstand mechanical shock better than typical epoxies that are higher on the Shore D scale.