The rapid development and mass production of integrated circuits (IC) have been key factors driving the evolution of miniature handsets. Now other fields such as UMTS, WiMAX, WiBro, base stations, repeaters and Customer Premises Equipment (CPE) are reaping the benefit of the integration of such modules. To satisfy this requirement, RFHIC has developed a new family—the 2WB series and 2GB series—of GaN two-stage 10 W hybrid transmitter power amplifier modules.

The utilization of a multi-chip hybrid module means that all the associated bias circuits and in/out matching circuits can be integrated within the highly conductive substrate. Also, GaN HEMT devices offer significant improvements that result in wide bandwidths, high voltage, high efficiency and high reliability, together with the provision of over 10 W of power.

Standard wideband plastic packages are not able to handle such output power. However, the multi-chip hybrid module can do so. By utilizing the multi-chip hybrid module, the company was able to make a cut-ration short circuit on the substrate.

Characteristic

For this family of two-stage GaN HEMT devices, 15.4 x 20 x 0.635 mm beryllium oxide (BeO) substrates are used. Specifically for WCDMA, WiMAX and military applications, input/output matching circuits and bias circuits were integrated into hybrids with 20 to 40 dB gain at frequencies below 6 GHz, producing over 10 W (CW) of output power. Figure 1 shows the 2 GB ceramic board.

The bias circuit supplies –1.3 V and 24 to 30 V to drain, and depending on the efficiency and output level, current can be controlled between 250 and 600 mA and used for Class AB or Class A adjustment.

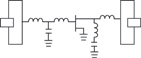

The input/output matching can be varied to fit the specific application. The use of high-Q capacitors, feedback circuits and internal matching are some of the ways that the characteristics of the GaN device can be adjusted and matched to the application. Figure 2 illustrates the internal matching wire map on the ceramic board, while Figure 3 shows the internal matching circuit.

The Substrate

The substrate uses 99.5 percent BeO, has a thermal conductivity of 285 W/mK, a coefficient of thermal expansion of 9.0, dielectric constant of 6.67 at 10 GHz (room temperature) and a dissipation factor of 0.0004 at 10 GHz (room temperature). 0.025-inch thick BeO substrates are used in order to reduce the thermal impedance and 30 units of the 10 W hybrid are arrayed in a 4.5 by 4.0 inch sheet. Figure 4 shows the side section of the ceramic board.

The substrate, shown in Figure 5, is thick film, which is plated with 15 µm copper, while high power and high frequency devices are achieved by plating with nickel and gold. For the GaN HEMT, the specification of the drive is a 3 W die with 10 fingers (gate length 0.5 µm and gate width 200 µm), while the second stage is a 10 W die with 40 fingers, as illustrated in Figure 6. To reduce the price, GaN is used on silicon as the substrate. Also, the bandwidth, gain, P

This new family of GaN two-stage 10 W hybrid transmitter power amplifier modules has been specifically designed for a wide variety of applications such as wireless base stations, repeaters, CPE and broadband access power modules: DTV (50 to 860 MHz), TRS TETRA (130 to 960 MHz), cellular (815 to 894 MHz), GSM (880 to 1,880 MHz), PCS (1750 to 1990 MHz), UMTS (1880 to 2170 MHz), WiBro MMDS (2,300 to 2700 MHz), WiMAX WiFi (3300 to 3800 MHz), military radio (500 to 3,000 MHz, 2500 to 6000 MHz) and phased-array radar (2700 to 3300 MHz, 5800 to 6000 MHz).

The GaN HEMT chip on a BeO ceramic board has the advantages of being small in size, having a good heat-sink and no need for an external matching circuit. Also, its modularity brings simplification, enabling mass production and resulting in low manufacturing costs.

Conclusion

RFHIC has invested a great deal of time and effort into developing and researching the next generation of power transistors that utilize GaN HEMT devices. The 10 W miniature hybrid module offers an easily adjustable matching process to suit the specific application and is mass produced at low cost. The usage of a multi-chip hybrid module on top of a BeO ceramic board minimizes the external circuits, resulting in high power and high gain, and a digital pre-distortion technique improves the linearity and efficiency.

Acknowledgment

RFHIC would like to acknowledge the role and cooperation of Nitronex in the development of these new products.

RFHIC

Suwon, Korea

+8231 2505011

www.rfhic.com

RS No. 302