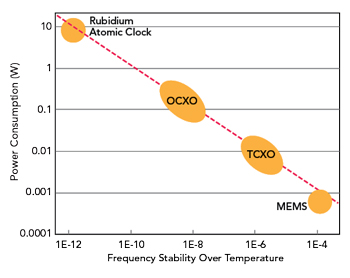

The choice of the local oscillator in an RF/microwave system is a significant decision affecting the performance of the system. In the case of an embedded application, where power is limited by battery operation, for example, optimizing the performance for the lowest dissipation is an important requirement. Figure 1 shows the frequency stability versus power consumption of several categories of quartz oscillators. The most basic use MEMS, while the most efficient are the oven controlled quartz oscillators (OCXO), where the quartz resonator is stabilized at a specific temperature.

The performance of an OCXO is primarily determined by two factors: the quality of the quartz resonator and the variation in quartz temperature with ambient temperature changes external to the OCXO. The frequency of any quartz oscillator will drift with temperature. For a 10 MHz oscillator, for example, the frequency drift between -40°C and +85°C can reach ±250 to ±500 Hz. Maintaining the quartz at a precise temperature will reduce the OCXO drift to between ±0.05 and ±0.5 Hz, depending on the OCXO.

Figure 1 Oscillator frequency stability vs. power consumption.

The quartz crystal in an OCXO is chosen to operate at an ultra-stable point, called the turnover point, where a small excursion in temperature does not significantly affect its frequency. The turnover point temperature must be higher than the maximum ambient temperature of the OCXO, so the internal heating mechanism and thermal regulation of the OCXO can be effective. To limit the power dissipation, the heated quartz must be well insulated from the outside, meaning the packaging must have the highest possible thermal resistance.

AT OR SC CUT?

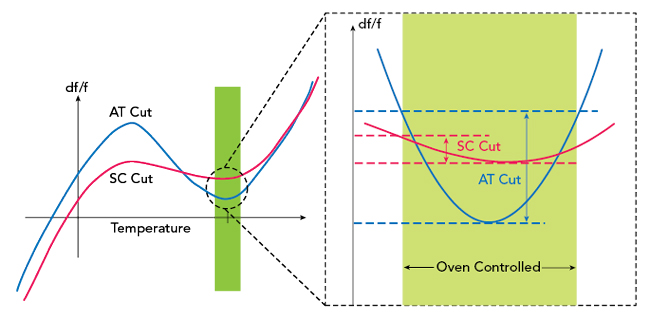

Using an OCXO requires choosing the type of quartz cut, AT or SC, and whether a simple or double oven is necessary to achieve the required stability. Figure 2 compares the frequency stability of AT and SC cut crystals. The difference can be significant, with SC cut crystals more stable than AT cut at a given turnover point. However, OCXOs using AT resonators are more common and, for low volume applications, provide an excellent trade-off between overall frequency performance and low power consumption. OCXOs using SC cut resonators represent the state-of-the-art and are used for the most demanding applications, those requiring very low long-term aging, precision ranging or satellite positioning. SC cut resonators are traditionally bulkier than AT cut.

Figure 2 Frequency stability of AT and SC cut crystals.

OCXOs guarantee high frequency accuracy, typically ±1 ppm. To achieve this, the OCXO manufacturer sorts the crystals and adds a trimming step during production. This adjustment, called frequency tuning, is important to guarantee the frequency precision when the OCXO is shipped. For example, if an OCXO is specified at 10 MHz, the frequency must be within a few Hertz - difficult to achieve without trimming. Yet, even with this accuracy, designers often want to adjust the frequency of the OCXO slightly; to enable this, a Vtune input is provided to tune the OCXO to the nearest milliHertz. For maximum precision, Syrlinks provides an internal, thermally-controlled reference voltage, Vref, which does not vary with the ambient temperature. This enables adjusting Vtune with a simple resistive divider, and the Vref ensures the maximum precision.

BATTERY-POWERED APPLICATIONS

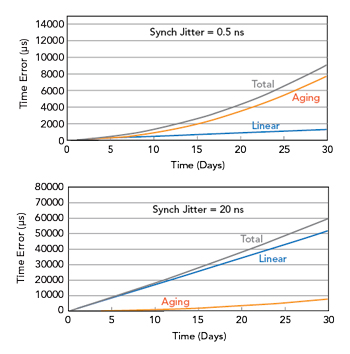

Figure 3 Accumulated time error of the low jitter SGTM (top) with an oscillator with initial synchronization of 20 ns (bottom).

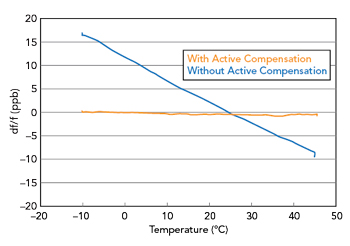

Figure 4 Improved OCXO thermal stability with active compensation.

To counter the generally higher power consumption of an OCXO compared with a temperature compensated crystal oscillator (TCXO), Syrlinks has developed a range of OCXOs combining low power consumption with small size and weight. The EWOS™range covers frequencies between 10 and 40 MHz, with thermal sensitivities between ±5 and ±250 ppb and power consumption between 50 and 400 mW at 25°C, about 10x lower power consumption than comparable OCXOs. Small size is achieved by adding an ASIC at the core of the OCXO to control all oscillator functions and manage the thermal behavior.

Syrlinks has developed a new timing module built using its OCXO and very low power digital electronics. The Syrlinks GNSS Timing Module (SGTM) precisely aligns the frequency and phase of the EWOS OCXO with the GPS signal. If the GPS reference is not available, the SGTM maintains accurate time, relying on the stability of the embedded OCXO. Without modifying the system, the SGTM can be used in some applications as an alternative to a chip-scale atomic clock (CSAC): its footprint enables quick pre-testing and deployment in production, making it an alternate second source if the CSAC is not available. The digital electronics of the SGTM provide advantages over the OCXO alone. The alignment of the OCXO’s phase and frequency with the GNSS signal is fully automated and achieves 0.5 to 1.0 ns jitter compared to the pulse-per-second (PPS) signal. This performance is linked to Syrlinks’ proprietary algorithm and hyper-fine tuning of the OCXO frequency using the Vref output.

The reduction of the residual initial synchronization error with the GNSS signal makes it easier to reveal secondary parabolic drifts related to long-term aging or thermal drift. Figure 3 compares the accumulated time error for a case where the initial synchronization is not close - the jitter is 20 ns - vs. the SGTM with 0.5 ns jitter. In the first case, the linear accumulated error masks the other types of drift, which must be post-processed to obtain better resolution of oceanic subsoils, for example.

In addition to generating a PPS signal from the OCXO frequency, the SGTM enhances key OCXO parameters such as thermal sensitivity. Understanding the thermal behavior of the EWOS10HP, Syrlinks developed a predictive algorithm for its OCXOs. Using the type of cut, AT or SC, each SGTM module is individually calibrated to compensate its intrinsic and natural thermal drift. For an EWOS10 AT cut resonator in a DIL14 enclosure, the algorithm reduces the thermal sensitivity from an initial value of around ±100 ppb to ±2 ppb. For Syrlinks’ most efficient OCXO with an SC cut resonator, the frequency stability over temperature can be improved to ±1 ppb. The thermal drift compensation technique has also been implemented on inherently more stable OCXOs, which are dedicated to underwater applications. For example, from -10°C to +45°C, the thermal sensitivity of the SGTM16HP-UW is reduced by 20x, from ±15 ppb without compensation to ±0.5 ppb, the thermal noise of the OCXO (see Figure 4).

OCXOs are essential for many RF/microwave applications. Syrlinks has combined its long-term understanding of crystal oscillator technology with digital electronics and algorithms to push OCXO performance to new frontiers.

Syrlinks

Cesson-Sévigné, France

www.syrlinks.com/en/time-frequency