Times Microwave Systems developed the family of TCOM® cables to be the most versatile line of low loss coaxial cables on the market. They exhibit the qualities of the popular LMR®cable family - low loss, flexibility and ease of termination - and then take it up a couple of notches. The TCOM cables are extremely rugged, often making them the first choice for field applications in both military and commercial markets. TCOM is also a cable with low passive intermodulation (PIM), maintaining solid dynamic PIM performance of approximately –160 dBc (i.e., using two 20 W carriers) even after bending, coiling and continuous flexure. TCOM is an excellent cable choice for mobile communications platforms such as “cell on wheels” and “cell on light truck,” as well as ground-based satellite communications up to and including Ku-Band.

Figure 1 Cross section of two TCOM cables, showing the multiple dielectric and shielding layers.

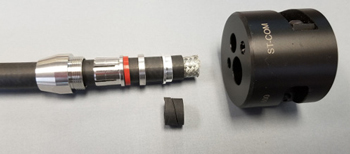

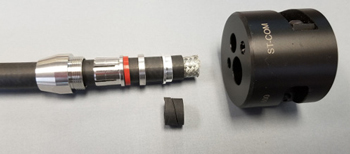

Figure 2 Prepping the TCOM cable for the connector.

The TCOM cables are built using the same dielectric cores as the LMR cables: a nitrogen-injected, closed cell polyethylene foam optimized for loss and ruggedness. The outer conductor construction is the greatest differentiator between the LMR and the TCOM cables. Where the LMR uses a single bonded metal-polyester shield under the round wire braid, the TCOM uses a multi-layer shield, which allows for direct, low resistance outer conductor contact, making this construction the most flexible, rugged, low loss, low PIM coaxial cable available (see Figure 1).

The first layer is composed of a silver-plated copper flat braid, which is designed to flex with the movement of the cable rather than hardening - which would occur with corrugated, tubular or bonded taped outer conductor constructions. The second shield layer is a helically-wrapped, aluminum-mylar-aluminum tape, which contains and maintains the flat braids during flexure. Last, the helically-wrapped tape is covered by a heavy tinned copper flat braid. This triple shield is optimized for flexure and provides greater than −100 dB shielding. Just prior to jacketing, the outer braids of these cables are flooded with a material that basically makes the cable self-healing. If the jacket were ever breached, however unlikely that is, moisture will not enter the cable itself. The jacket is a very strong, pliable, UV-resistant polyurethane compound.

It is not often that high shielding and the ability to perform with continuous flexure are found in the same cable - not to mention excellent dynamic PIM performance, abrasion and chemical resistance and core sizes large enough to satisfy feeder cable lengths in most field applications. Times Microwave offers these rugged TCOM constructions with both a solid center conductor (PUR-DB) and a seven-strand center conductor (Flexstrand-DB), both available in 1/4 , 3/8 and ½ in. The PUR-DB cable is flexible, and the Flexstrand-DB is very flexible. These cables have had rigorous flex testing in nearly every conceivable configuration: coiling and uncoiling, bend and reverse bending (Tic-Toc), Flex Trac and simulated continuous handling.

As rugged as these cables are, they would not realize their full potential without the TCP connector design. This unique construction, which uses materials, plating and tolerances optimized for low PIM, has a BeCu spring collet with rows of barbs on each finger, which grip the cable jacket roughly ¾ in. behind the electrical contact when the back nut is torqued (see Figure 2). This unique construction isolates the bulk of any sideloading force on the cable from the electrical transition between the cable and the connector. TCP connector options comprise male Type N, 4.3/10.0 and 7/17 DIN, which are available for all cable diameters.

Understanding that many applications are demanding of coaxial assemblies, Times Microwave has designed the connectors to be field replaceable and supplies a set of five, easy-to-use tools for cutting, prep and pin crimping, assuring reliable, low PIM terminations in the field (see Figure 3).

Figure 3 One of the tools used to replace a connector in the field.

Times TCOM coaxial cables were developed for a wide range of applications: low PIM, high shielding and harsh environments, including where a cable sees handling and movement after the initial installation or where flexure or coiling is expected through its life. With its rugged construction, the TCOM cable is also a good choice for flexing applications where PIM is not a requirement.

Times Microwave Systems Wallingford, Conn.

www.timesmicrowave.com