The challenge of phase stability in coaxial cable assemblies is a recurring topic, which an increasing number of equipment manufacturers are encountering when designing or verifying their systems. Any application where temperature plays a role is subject to phase changes.

For example, temperature fluctuations influence the signal transmission in differential pairs, which are used to eliminate noise and increase a system’s digital data rate. If every channel uses at least a pair of cables to transmit or receive information, the effect of temperature will multiply and will tangibly affect phase stability, meaning different electrical lengths for the same application. Phased array antennas are another example of the relevance of phase sensitive components, since the accuracy of the system relies on the phase of each individual component in the signal chain. Satellites, such as used for synthetic aperture radar, are even more sensitive to the environment. Typically, a cable bus surrounds the satellite and is exposed unpredictably and simultaneously to sun and shadow. Unless phase invariant cables are installed, the effects of these temperature differences will need to be corrected, often using complex algorithms or additional subsystems. In test and measurement applications, a high degree of measurement accuracy is very important, such as network analyzers requiring phase invariant components.

As seen, phase stable interconnects are an essential part of the system and must be comprehended from the beginning of the design. Failure to do so can unnecessarily increase the cost - multiplying by several hundreds the cost of an individual cable assembly. It may also have severe consequences in the final application, whether radio systems, radar, direction finding or transport signaling.

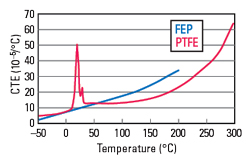

Figure 1 Expansion of PTFE and FEP vs. temperature.

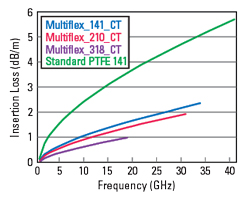

Figure 2 Insertion loss vs. frequency of standard PTFE and Multiflex CT cables.

The challenge to achieve phase stability over temperature in coaxial cables begins with one of the most common dielectric materials, PTFE. Since PTFE offers excellent dielectric properties at high frequencies, it should be no surprise that most microwave cables use this material. Unfortunately, its phase change characteristic with temperature is nonlinear, especially noticeable in the 15°C to 25°C range, an effect known as the “PTFE knee” (see Figure 1). The figure compares the coefficient of temperature expansion (CTE) of PTFE with the fluoropolymer FEP, which has a smooth change over temperature.

To end the compromise between the optimal dielectric properties and excellent phase stability, HUBER+SUHNER has released a Constant over Temperature (CT) cable family. The family was developed for phase-critical applications requiring precision electrical length, and it offers three platforms providing stable and reliable interconnect solutions for a range of applications.

For static applications requiring a stationary connection with excellent VSWR, HUBER+SUHNER offers its semi-rigid CT product, with the added capability to fit in small, high density areas and save connection time. Lightweight, these semi-rigid cable assemblies reach 40 GHz and are available in 0.086 in. and 0.141 in. sizes. They are widely used in test and measurement and aerospace and defense subsystems.

For static applications needing a hand-formable cable without tooling, HUBER+SUHNER offers the Sucoform CT. Sucoform CT enables space saving routing and is especially suitable for delay lines in communication systems, where low passive intermodulation (PIM) is required. Sucoform CT is also available in 0.086 in. and 0.141 in. sizes, with frequency coverage to 40 GHz.

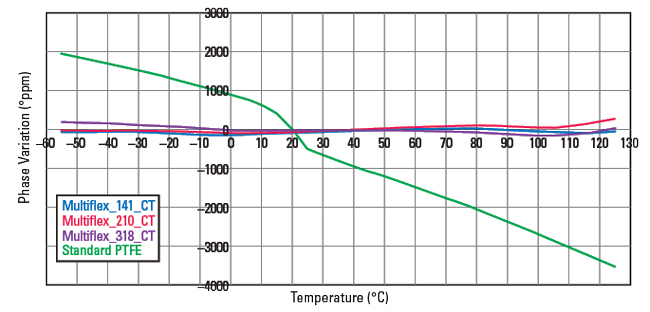

HUBER+SUHNER also provides a solution for “dynamic” applications needing a combination of high flexibility and high shielding effectiveness at high frequencies. Multiflex CT products are quick and easy to assemble, and they comply with the MIL-DTL-17 standard. In addition to excellent phase stability over temperature, Multiflex CT cable assemblies have low weight and insertion loss and are available in three sizes: 0.141 in., 0.210 in. and 0.318 in. Figure 2 compares the insertion loss of the standard PTFE cables with the Multiflex CT family, and Figure 3 similarly compares the phase stability over temperature. With the proper connectors, which are also available from HUBER+SUHNER, Multiflex CT cables can be used for thermal vacuum applications.

The full CT cable family provides excellent phase and insertion loss stability with temperature change, as well as outstanding return loss and shielding effectiveness. This cable assembly family ensures system performance is stable beyond a single temperature. More information about the CT cable family of products is available using the QR code.

Figure 3 Phase variation vs. temperature of standard PTFE and Multiflex CT cables.

HUBER+SUHNER

Herisau, Switzerland

www.hubersuhner.com