The old adage “time is money” has never been more pertinent to industry than it is today. As companies try to streamline processes, maximize throughputs and reduce budgets, selecting the right test equipment can be a difference maker on the path to success. To help manufacturers meet these objectives, Anritsu recently introduced the MA242x8A and MA243x0A USB power sensors, which utilize advanced processing circuitry and improved algorithms to provide measurement speeds hundreds of times faster than older generation sensors.

The MA24208A and MA24218A are designed with a patented three-path architecture that provides true RMS power measurements across the entire frequency range (10 MHz to 8 or 18 GHz) and dynamic range (-60 dBm to +20 dBm). True RMS measurements are modulation independent, so these sensors can be used to measure the average power of almost any signal. In addition, the MA242x8A sensors have advanced triggering capabilities that facilitate time-dependent power measurements in signals like WiMAX, GSM and LTE. The MA24330A, MA24340A and MA24350A provide fast, accurate CW measurements up to 33, 40 and 50 GHz, respectively. These sensors also have accelerated measurement speeds and triggering capabilities, which make them suited for automated test situations like manufacturing lines or calibration procedures. The MA243x0A sensors are a perfect solution for test engineers who currently use Anritsu’s popular MA247xD and MA244xD traditional sensors, yet would like the advantages of the USB form factor.

Impact of Measurement Speed

The faster measurement speed of the MA242x8A and MA243x0A allows companies to reduce — even eliminate — bottlenecks in regular test processes, increasing the throughput of the system. Increasing throughput in manual or automated test systems has several positive business impacts. In cases where the system cannot keep up with demand, companies may be late on orders or have to turn down new business. Solving those problems through increased throughput will improve customer satisfaction and open the door for more orders. Increased throughput may also allow companies to decrease the number of test systems required to meet demand. That leads to both capital and operational expense savings and frees valuable floor space that could be used for new products. Finally, an improved throughput can improve time-to-market, which not only increases customer satisfaction but can make the difference when bidding against other companies for new business. The improved measurement speeds of the Anritsu USB sensors can add to the top line, while simultaneously helping control costs.

USB vs. the Traditional Meter/Sensor

In one small package, Anritsu’s USB power sensors provide all the same quality measurement performance as a traditional power meter and sensor combination. They are portable and easy to share between test groups, which makes it possible to accomplish more testing with fewer sensors. By combining the meter and sensor into the same package, the need to perform reference calibration is eliminated, which removes a step from long test procedures, again increasing throughput. Rather than having a built-in user interface, USB sensors are controlled directly with a PC or by Anritsu’s PowerXpert® software, which can be downloaded to any PC for free from Anritsu’s website. License-free software means Anritsu sensors can be controlled by any PC in the lab, not just the one that happens to have the license installed. That saves engineers time and hassle and greatly simplifies the test process. The sensors are also fully remote programmable with standard power sensor commands, which makes them easy to integrate into any automated test system. Anritsu’s USB sensors are less expensive than their traditional meter/sensor counterparts, which means buying a USB sensor will provide the same measurement quality as a traditional setup, in a smaller package, with improved performance and for a lower price. In addition, Anritsu’s USB power sensors have the industry’s highest levels of protection from accidental over powering, helping defend the budget from unplanned repair or replacement costs.

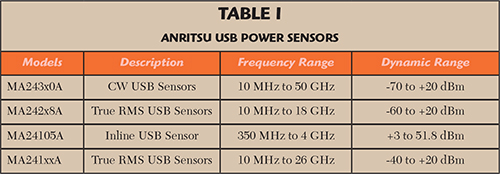

Beyond the MA242x8A and MA243x0A, Anritsu offers several other USB sensors for different needs (see Table 1). The MA24105A inline USB sensor can be placed directly in line with a transmission system to measure both forward and reverse power. It can be used for constant monitoring of active systems, like wireless base stations, without interrupting transmission. The built-in coupler reduces the number of external elements in the system, which decreases mismatch uncertainty and protects signal integrity. The forward power detector has high video bandwidth to capture both average and peak power. Anritsu also has a budget line of three-path, true RMS USB sensors. For those who don’t need the higher measurement speeds or wide dynamic range of the newer USB sensors, the MA241xxA sensors are a suitable alternative that provide quality measurements at a budget saving price.

Anritsu

Morgan Hill, Calif.

(408) 778-2000

www.anritsu.com