In the evolution of multiport connectors, Spectrum Elektrotechnik GmbH has played an important and key role in developing products that offer practical solutions. Years ago all interconnections were made by using standard connectors, such as N, TNC, BMA, SMA, etc. However, as packaging density became a requirement, smaller connectors (such as SSMA) were developed. Although connectors became smaller, space was still needed for connecting and disconnecting, using a wrench for tightening and loosening.

The development of snap-on connectors was a breakthrough that addressed the need for connections in compact situations but one problem still existed – manually connecting every single line. The more assemblies to be connected, the greater the possibility of making a wrong connection as well as the issue of connections becoming loose during vibration or shock – although connectors like the full detent SMP already provide a safe connection.

FOOLPROOF CONNECTIONS

The use of the MIL-DTL-38999 shells and the development of size 8 and 12 connectors for microwave connections was a first step in the right direction towards making proper connections in seconds for a number of microwave lines. The availability of five different keyed shells (0 and A to D) reduced the risk of connecting the wrong shells and made connections foolproof. Patterns from several manufacturers became available, usually mixing a number of microwave inserts of size 8 or 12, with a number of signal lines included.

Figure 1 The traditional SQ-8, connecting 8 low loss cable assemblies in seconds.

The system is useable for low frequency applications, but there is a disadvantage at higher frequencies. The soft rubber does not guarantee exact alignment of size 8 or 12 contacts or the perfect mating of the male/female interfaces, which is a prerequisite for high frequency applications.

Advanced installations require a high number of connections in as small a shell as possible and often require only microwave connections and not signal lines. The microwave cable assemblies must be low loss and must utilize high density dielectrics, since long cable lengths are often required. Applications for such cable assemblies are in surveillance aircraft and other vehicles that use microwave equipment. Similarly, there can be a large number of cable assemblies in medical applications and test centers, which must be connected safely and quickly.

Spectrum Elektrotechnik GmbH was the first company to develop the circular SQ-Series, using the MIL-DTL-38999 shell, series 3, size 21, packing eight microwave cable assemblies of 4.3 mm diameter as compactly as possible (see Figure 1). In addition, the series features the quick replacement of defective assemblies, using bayonet catch inserts and operating to 24 GHz with low VSWR.

The TQ-Series was developed to address the requirement for more connections and low loss microwave lines to be connected within seconds. It adheres to MIL-DTL-38999 with a size 25 shell, connecting up to 12 low loss microwave cable assemblies of 3.2 or 4.3 mm diameter in seconds, using the proven front end design of the SQ-Inserts for the frequency range up to 24 GHz and newly designed inserts for applications to 40 GHz.

Figure 2 The TQ-Series, connecting up to 12 assemblies in size 25 shell per MIL-DTL-38999.

CABLE ISOLATION

The TQ-Series (shown in Figure 2) is available for 12, 10, 8, 7 and 4 microwave cable assemblies using 7.6 mm diameter cable assemblies with a low loss of 0.65 dB/m (0.2 dB/feet) at 18 GHz. Since the TQ-Series uses a common ground among the cable assemblies within one shell, the IQ-Series has been designed to isolate the assemblies from each other.

Although it takes only seconds to connect series 3 MIL-DTL-38999 shells, the shells of MIL-DLT-38999, Series I, incorporating a bayonet catch system, has been developed to provide even faster connection and disconnection. While the BQ-Series employs common ground cables, the CQ-Series isolates the cable assemblies from each other within the circular shell.

Certain applications demand specific solutions. An aircraft, for example, has one multiport outside and one mating port inside. Therefore pressurized units are offered that satisfy tests in accordance with EIA-364-02C.

Since size 21 and 25 circular shells are too big for certain requirements, Spectrum has used the MIL-DTL-38999, size 13, circular housing that packs nine 2.4 mm diameter microwave cable assemblies into the housing and operates to 40 GHz. The design goal is a VSWR of 1.2:1 max at 40 GHz with the current VSWR of 1.35:1.

Figure 3 TQ-9 Multiport: 9 × 40 GHz coaxial cable assemblies in the MIL-DTL-38999, size 13.

Spectrum Elektrotechnik GmbH is currently engineering a size 25 circular unit, carrying 19 microwave cable assemblies and operating to 40 GHz. An additional development is a multiport design to 67 GHz (see Figure 3), incorporating a minimum nine assemblies in a size 13 circular shell adhering to MIL-DTL-38999, guaranteeing a maximum VSWR of 1.35:1 for each pair of the assemblies at 67 GHz.

RECTANGULAR CONNECTORS

Rectangular multiport connectors often fit the system requirements better. For a special project, the

RQ23-DC26 (shown in Figure 4) incorporates 23 microwave cables and 26 signal connections in a rectangular housing has become a reality. Spectrum’s Push-On SMAs were used as inserts to meet the customer’s specific requirement for individual testing of the cable assemblies while already aligned in the shell and using standard SMA assemblies. The push-on connectors offer a float mount capability at low cost.

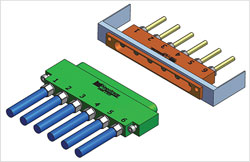

Looking forward, Spectrum Elektrotechnik GmbH is developing a number of small rectangular multiport connectors using different shapes in order to fit the system’s dimensional requirements – see Figure 5. The shells will carry 4, 8, 10, or 12 cable assemblies and utilize a specially developed locking mechanism.

Figure 4 The standard RQ23-DC26 using 23 coaxial microwave assemblies and 26 signal lines.

Figure 5 The new rectangular multiport designs featuring 4, 8, 10 and 12 coax connections.

There are proposals for carrying up to 80 connections in a rectangular multiport. Due to the high number of connections and disconnections to be made at once, focus needs to be directed to the float mount capability of the units, their safe connection and electrical performance, with special attention to the insertion and withdrawal forces and safe locking. Using its experience Spectrum Elektrotechnik GmbH is constantly developing multiport units to meet customer requirements.

Spectrum Elektrotechnik GmbH

Munich, Germany

+49 89 3548040

www.spectrum-et.com