M/A-COM is now offering new lightweight cable assemblies utilizing the FN34RXLW cable, a lightweight version of its proven FN34RX cable assemblies. This new product offering is intended for use in high performance military airborne applications. All popular assembly configurations are readily available with reduced mass at competitive prices. Weight reductions of over 30 percent are available compared to traditional cable designs.

M/A-COM is now offering new lightweight cable assemblies utilizing the FN34RXLW cable, a lightweight version of its proven FN34RX cable assemblies. This new product offering is intended for use in high performance military airborne applications. All popular assembly configurations are readily available with reduced mass at competitive prices. Weight reductions of over 30 percent are available compared to traditional cable designs.

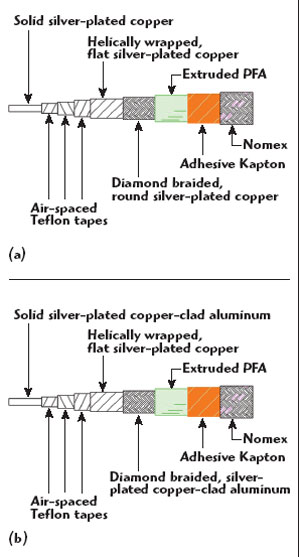

The FN34RX assembly is a DC to 18 GHz, 0.34" diameter cable, operational at temperatures up to +200°C and used for electronic warfare and other special purpose applications. The new, reduced weight version FN34RXLW, using a silver-plated copper-clad aluminum center conductor and a silver-plated aluminum shielding, exhibits a greater than 32 percent weight reduction with no impact on performance. Figure 1 compares the construction of these two cables showing the difference in materials; other FN-RX assemblies can also be provided in lightweight versions.

Fig. 1 Cable contruction details; (a) standard cable FN-RX and (b) reduced weight FN-RXLW cable.

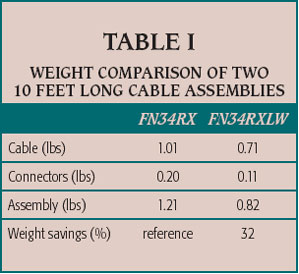

Complementing the lighter FN34RXLW cable, all assemblies now feature new, reduced weight and volume connectors. The connectors retain the conventional ETNC, SMA and N interfaces while incorporating new materials. Excess bulk has been excluded to decrease both weight and space. Figure 2 compares the traditional and reduced weight ETNC male, non-replaceable connectors showing the reduction in material used in their fabrication. Cables are available with ETNC, SMA, N, or other connector interfaces, and all incorporate new materials and have excess material removed to save weight. Table 1 compares the weights of a 10 ft. cable assembly with traditional ETNC plug NR connectors and FN34RX cable to that of the lightweight FN34RXLW cable and redesigned ETNC plug NR connectors.

Fig. 2 ETNC plug NR connector; (a) standard FN34RX and (b) lightweight FN34RXLW.

The electrical specifications for assemblies based on the new lightweight cable and connectors remain unchanged. In particular, there is no change in VSWR or insertion loss. Figure 3 shows that the insertion loss specification is valid for both cable types. Similarly, the environmental characteristics remain unchanged. The lightweight assemblies can withstand the same harsh environment as the traditional assemblies. This includes altitudes from ground level to over 70,000 feet and temperatures from –55° to +200°C.

Fig. 3 Insertion loss at 25°C for the two cables, FN34RXLW and FN34RX.

The mechanical characteristics of the lightweight cable assemblies are similar to those of the existing assemblies. The minimum bend radius remains the same. There is approximately a 10 percent reduction in the number of flexure cycles the cable can withstand; however, this is not significant for most applications, including fixed airborne applications.

The lightweight cables are highly recommended for all airborne applications including UAVs. In commercial applications, the weight savings translates into improved fuel efficiency or increased cargo capacity. In military applications, the reduced weight enables improved flight characteristics or provides margin for the inclusion of additional systems or armament.

In summary, M/A-COM has developed a line of lightweight cable assemblies that are over 30 percent less in weight compared to traditional designs. This is accomplished by using different construction materials in the cable assembly and reduced weight connector designs. The lightweight cables are ideal for use in airborne applications without sacrificing performance.

M/A-COM Inc.,

Lowell, MA

(800) 366-2266,

www.macom.com.