Holzworth Instrumentation has an excellent reputation for its versatile product offering of phase coherent, ultra low phase noise RF synthesizers. What many engineers do not realize is that the RF synthesizer products have been a fundamental building block to Holzworth’s premier line of products. Customers are pleasantly surprised to learn that Holzworth Instrumentation was originally founded to create the industry’s most innovative phase noise analysis products.

Holzworth engineering designs every product from the ground up, right down to each subsystem allowing for full control of the most necessary performance variables. Review of a Holzworth product specification reveals that the design did not originate from a textbook architecture. The key to Holzworth’s success in a market saturated with mature competition is to provide highly reliable, innovative products that offer unique performance advantages.

PRODUCT INCEPTION

For decades, phase noise has been a performance parameter that is often avoided (even ignored), being written off as something that “only radar companies need to worry about.” The primary concerns with making phase noise measurements include: test complexity, capital costs and support costs. When considering incorporation of phase noise test into a manufacturing test line, “throughput” is added to the top of the list of concerns.

From initial inception to date, Holzworth has been working with phase noise test engineers throughout many industry sectors. Beyond accuracy, reliability, etc., market research consistently revealed three things: First, can you make it extremely easy to operate? Second, can you improve the measurement speed while hitting ultra low noise floors? Third, can you price it so that one can justify a purchase for multiple test lines? The HA7400 series specifically addresses these three needs with some additional benefits. Product highlights include:

- 0.1 Hz to 1 MHz, adjustable offset

- -180 dBc/Hz½ in 20 sec (1 Hz to 1 MHz)

- Auto-calibration, self-test

- Integrated frequency counter

- Integrated power meter

- Low noise DUT power supplies

CORE DESIGN

At the core is a fast, spur-free, cross correlation engine. There are many phase noise analysis solutions available today that provide single channel analysis. Some are better than others. Someone who understands the intricacies of the measurement could even use a high end audio card to setup a valid measurement system, but with a limited floor and frequency offsets.

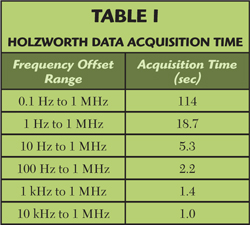

The need for lower measurement floors is driven by DUTs that exhibit very low phase noise characteristics. It is not good enough to have a measurement system with a noise floor that is close to that of the DUT as there are tolerances and variables that contribute to the measurement, resulting in incorrect data. Spur-free cross correlation provides a measurement floor that is lower than that of the DUT, resulting in accurate measurements without questionable artifacts. As outlined in Table 1, the HA7400 series are speedy cross correlators. More details on the advantages of cross correlation analysis can be referenced in the Holzworth authored article: “Cross Correlation in Phase Noise Analysis,” Microwave Journal, February 2011.

INTUITIVE INTERFACE

Figure 1 The HA7400 series are speedy cross correlators.

One of the most fundamental elements of Holzworth analyzers is a software interface (see Figure 1) that is so intuitive that a user with zero knowledge of phase noise test can be taking valid data after 15 minutes of instruction. There is no need to have a phase noise expert on staff to constantly support the test process.

The interface for the HA7400 series is a quantum leap in the industry in terms of ease of use. Embedded diagnostic hardware provides the information the software needs to auto-detect, lock, calibrate, acquire data and even warn if the data is “out of character” or if more correlations are required. Interface highlights include drag and drop markers, user defined test limit, overlay ASCII data from other instruments and a touch screen compatible GUI.

Often, a proprietary PC and/or integrated front panel is the failure mechanism to a test system. Holzworth analyzers are virtual instruments that can be controlled by any standard PC (driver free) to further eliminate potential technical issues.

APPLICATION DRIVEN DESIGNS

Many phase noise analyzers available today are loaded with internal hardware settings that are well beyond phase noise (and jitter) test. Added functionality makes for a higher level of system complexity, slower acquisition times, potential system instabilities and a greater price tag. Holzworth currently offers three phase noise analyzer products within the HA7400 series that are individually priced at under $25,000 US. Each model targets dedicated phase noise measurements.

Figure 2 HA7401A/HA7402A absolute measurements.

FIXED CRYSTAL MEASUREMENTS (Model HA7401A): Crystal references are the thread that tie all instruments together and often set the frequency accuracy and the phase noise of an entire system. It is also one of the more difficult measurements because of the extreme low noise that many oscillator designs exhibit. Figure 2 contains a block diagram of the HA7401A fixed frequency analyzer for making absolute phase noise measurements at fixed frequencies. 10 MHz, 100 MHz and other common frequencies are available.

ABSOLUTE MEASUREMENTS (Model HA7402A): For those applications (crystals, DROs, synthesizers, etc.) where variable test frequencies are necessary, the HA7402A is a more versatile solution. The HA7402A allows for two LO input ports instead of having a factory set fixed frequency (refer to the “CORE” outlined in Figure 2). The user sets the test frequency by supplying two identical, non-coherent source signals for making DUT measurements between 10 MHz to 1.2 GHz. Measurements to 18 GHz will be available by June 2011.

Figure 3 HA7403A residual (additive) measurements.

RESIDUAL (ADDITIVE) MEASUREMENTS (Model HA7403A): Residual phase noise measurements are of a completely separate classification. Low noise amplifiers, frequency dividers, frequency multipliers, etc., can all be measured with the self calibrating, HA7403A residual phase noise analyzer. Figure 3 contains a basic block diagram of the residual analyzer.

RELIABLE

Cooling fans and ground loops are typical culprits of performance issues amongst traditional test systems. Holzworth analyzers utilize a fan-less chassis that offers significant advantages in terms of noise floor and spurs. A centralized heat sink is used to efficiently dissipate internal heat, while doubling as a common ground to completely eliminate ground loops. The 20 lb (9 kg) chassis is fully sealed, rugged and uniquely portable for field applications, providing consistent results from location to location without the worry of recalibration support or repair.

Time is money. If the need for support were to arise, the HA7400 series GUI maintains a detailed system log file that can be used for remote diagnostics. The user simply exports the file and e-mails it to the factory. Real time trouble shooting eliminates questions relative to the analyzer so that the user can be up and running as quickly as possible.

Engineers are becoming more and more aware of how the effects of poor phase noise performance can ripple through an entire system. The result is an increasing trend for mandatory phase noise test being specified at the subsystem and component levels. Holzworth’s expanding line of fast, cost-effective phase noise analyzers provides an excellent fit for dedicated manufacturing phase noise test with the added benefit of having the accuracy necessary for product development.

Holzworth Instrumentation,

Boulder, CO

(303) 325-3473

www.holzworth.com