MAGTREX™ copper clad laminate with matched permittivity and permeability is another industry first from Rogers Corp. MAGTREX materials have a refractive index dramatically higher than can be achieved in a composite printed circuit board (PCB) material, with an impedance matched to free space. This enables antenna designers to create antennas with a combination of size, efficiency and bandwidth significantly greater than for antennas produced on traditional high dielectric constant substrates.

Antenna miniaturization has been an important topic since the advent of wireless communications. The physical size of an antenna is generally a function of its free space wavelength: λ = c/f. Antenna miniaturization is particularly important when the operating frequency is low, which normally requires large antennas. Of course, like most engineering problems, antenna miniaturization is a balancing act among trade-offs within fundamental limitations. Generally, when an antenna is miniaturized, its bandwidth, efficiency or both will decrease, limiting the practical use of electrically small antennas.

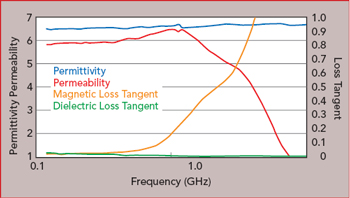

Figure 1 Typical MAGTREX 555 properties at 23°C.

One common method for miniaturizing antennas and other wavelength-based RF structures is using materials with a high refractive index:  , where μr is the relative permeability and εr the relative permittivity. With these materials, the effective propagation velocity is slowed below the speed of light, reducing the physical distance of a wavelength in the structure. With most available materials used at frequencies above a few MHz, µr is assumed to be 1, and any increase in refractive index is obtained by increasing the relative permittivity (εr). While this is effective for antenna miniaturization with some performance requirements, it introduces trade-offs. If the dielectric constant of a substrate is increased, while the permeability remains constant, the substrate’s intrinsic impedance (μ/ε) will decrease, adding design complexity. For a given impedance and thickness, the width of the transmission line will decrease, resulting in higher loss per unit length. When the intrinsic impedance drops, the structure is no longer matched to free space, reducing the radiation efficiency of the antenna. MAGTREX materials increase μ and ε simultaneously, mitigating those challenges.

, where μr is the relative permeability and εr the relative permittivity. With these materials, the effective propagation velocity is slowed below the speed of light, reducing the physical distance of a wavelength in the structure. With most available materials used at frequencies above a few MHz, µr is assumed to be 1, and any increase in refractive index is obtained by increasing the relative permittivity (εr). While this is effective for antenna miniaturization with some performance requirements, it introduces trade-offs. If the dielectric constant of a substrate is increased, while the permeability remains constant, the substrate’s intrinsic impedance (μ/ε) will decrease, adding design complexity. For a given impedance and thickness, the width of the transmission line will decrease, resulting in higher loss per unit length. When the intrinsic impedance drops, the structure is no longer matched to free space, reducing the radiation efficiency of the antenna. MAGTREX materials increase μ and ε simultaneously, mitigating those challenges.

For many years, magnetically permeable materials have been used to produce antennas with extremely small electrical sizes: ferrite core loop antennas for AM radio and other medium frequency (300 kHz to 3 MHz) and high frequency (3 to 30 MHz) applications. These produce receiver antennas which have dimensions in the tens of centimeters at frequencies which have wavelengths from 10 to 1000 m. However, the efficiency of these antennas has limited their practical use to receivers, and the availability of materials restricts frequencies to the low MHz.

Interest in using magnetically permeable materials from the hundreds of MHz to GHz has persisted, increasing after a foundational paper by R. C. Hansen and Mary Burke, who derived a fundamental relationship between microstrip patch antenna bandwidth and magnetic permeability. This publication reached an important conclusion: the reduction in patch antenna size attributable to magnetic permeability does not reduce antenna bandwidth. For a given miniaturization value (the με product), the bandwidth of the antenna improves by a factor of μ.

However, producing a suitable magnetically permeable composite material for use at frequencies above 100 MHz is a monumental challenge, requiring a combination of materials science, chemical engineering and electrical engineering. After years of research, Rogers Corp. introduced MAGTREX 555 materials in 2018. These laminates offer a permeability of six with a matched dielectric constant, with or without copper cladding. The combination of a high refractive index and intrinsic impedance enables designers to use the material and realize advantages over conventional PCB laminates. MAGTREX laminates have well-behaved magnetic properties to roughly 500 MHz, the region where antenna size is the greatest challenge. The photo shows a 300 MHz patch antenna measuring 15 cm x 15 cm.

MAGTREX materials can be used to partially load the area between the radiating structure of an antenna and the ground plane. By optimizing the material shape and thickness, the designer can control the degree of miniaturization and manage the impact on bandwidth and the material’s effect on efficiency. Rogers has presented one case study in the webinar “An Introduction to Magneto-Dielectric Materials for Antenna Miniaturization,” available for viewing at microwavejournal.com/events/1810.

Rogers Corp.

Chandler, Ariz.

www.rogerscorp.com/techub