The evolution of electronics technology is driving communications data transfer rates, which means larger bandwidth. To get larger bandwidth, systems must move up in frequency, and moving up in frequency to get more bandwidth requires higher performance connectors.

W-Band applications, i.e., from 75 to 110 GHz, have grown significantly over the last few years, such as automotive radar and wireless communications backhaul. To support the development and production of these and future systems, broadband device characterization extending beyond 110 GHz, i.e., into D-Band, is required. To address this need, Anritsu has developed the first 0.8 mm connector.

For a new frequency band, connectors were historically created ahead of or in parallel with the test and measurement equipment supporting the applications. Connectors like K, V and W1 have enabled new test equipment capabilities. In some cases, the connector was developed first, with the equipment developed quite a few years later, like the 1 mm connector, which extended coaxial measurements to 110 GHz.

Typically, waveguide has been used for interconnections at the higher end of the frequency spectrum. Waveguide accomplishes the task of sending signals through devices with low loss; however, it is not the optimal solution. As a frequency-banded component, waveguide lacks the advantage of broadband frequency coverage and single-sweep measurements. Waveguide adds complexity for any measurement to characterize broadband performance from low frequency to mmWave frequencies past 110 GHz.

Coaxial connectors are preferred for interconnections, especially for test and measurement. They have advantages like single-sweep capability, ease of use for measuring and testing devices and frequency scalability. Coaxial connectors avoid impedance variations between interfaces, like coaxial to waveguide, which introduce uncertainty.

DESIGN CONSIDERATIONS

To understand the 0.8 mm connector design, consider the electrical and mechanical characteristics of a connector. IEEE P287 is the standard for precision coaxial connectors covering DC to 110 GHz, outlining the electrical and mechanical properties for connectors down to 1 mm. IEEE P287 does not currently define the 0.8 mm connector; however, because frequencies above 110 GHz will be important in the future, 0.8 mm will eventually be included in the spec. The electrical characteristics of a connector define the frequency coverage and impedance, while the mechanical characteristics address how the connector design supports repeatability and mating. Combined, these characteristics, which are generally listed in a technical datasheet, are important design considerations.

The upper frequency of a connector is determined by the equation

where fc is the air cutoff frequency, c is the speed of light (3 x 108 m/s), ϵr is the relative permittivity, μr is the relative permeability and λc is the line length.1 For the 0.8 mm connector, fc is approximately 166 GHz, assuming a perfect air dielectric. This maximum frequency is hard to achieve; the actual usable frequency is a percentage of the ideal because the internal components of a connector introduce transitions between air and the various materials, creating resonances that degrades the upper frequency. Although the 0.8 mm connector does not have a defined maximum frequency, which is still to be specified, connectors operating to 145 GHz are commercially available. A summary of RF connector types, including the 0.8 mm, is provided in Table 1.2

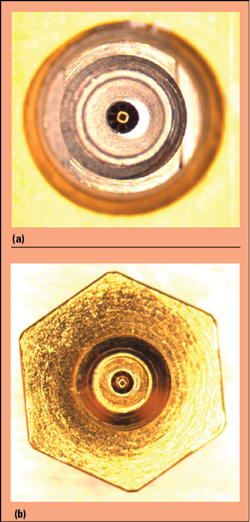

Figure 1 1 mm (a) and 0.8 mm (b) connectors.

Impedance is a primary electrical requirement, because system performance is based on the ability to prevent or design around impedance mismatch. For connectors in this frequency range, 50 Ω is the standard impedance; designs must ensure that the connector and all internal parts are as close to this impedance as possible. Impedance must be well controlled for a connector that spans from DC to above 110 GHz. The center conductor and dielectric support beads play crucial roles keeping the impedance within an acceptable tolerance.

Most mechanical characteristics are defined by a connector standard, such as IEEE P287, which outlines the mechanical properties, such as coupling nut tolerances, line size and dimensions. The standard assures mechanical compatibility between connector manufacturers. While the general mechanical assembly is outlined, additional connector details are required to ensure good performance: slot-less or slotted, pre-alignment before mating and environmental classification based on the end product.

THE 0.8 mm CONNECTOR

Moving up in frequency past W-Band starts with the requirement that the new connector must provide low insertion loss with metrology-grade and mode-free performance to the desired upper frequency. This is not easy, requiring many design decisions. The 1 and 0.8 mm connectors are similar - they are very close in mechanical size and share many external physical similarities - however, there are many internal differences (see Figure 1). While some 1 mm technology could be leveraged, the 0.8 mm connector needed several new design elements to optimize performance.

In the frequency domain, a good interface should minimize insertion loss to minimally degrade the loss budget of a system. Unknown impedances between interconnects can cause reflections, affecting insertion loss even before the signal reaches the device being tested. The signal should be preserved between interfaces. Impedance variation is also an issue in the time domain, so the eye diagram of an interface should have an optimal opening to ensure a clear and undistorted signal. The eye diagram is a figure of merit for designers creating digital circuits operating to mmWave frequencies. Whether for RF or high speed digital, the connector should be designed and built to provide performance that makes the connector transparent in the measurement environment.

What does it take to get the connector’s upper frequency past 110 GHz with good impedance matching, metrology-grade performance and a mechanical design that makes it durable and performing well? It requires identifying the mechanical issues influencing performance above 110 GHz, quantifying and correlating simulations with fabricated connectors and exploring materials for novel new assemblies. Because the scope of the design is so wide, this article focuses on the mechanical issues and new assemblies.