When did Guzik Technical Enterprises become a company, and what problem did the firm aim to solve?

Guzik was founded in the early 1980s by Dr. Nahum Guzik. The company was founded to address the challenge of reducing disk drive validation tests from days or weeks to minutes.

Guzik Technical Enterprises continues to develop innovative test solutions aimed at verifying signal and overall magnetic recording integrity for disk drive heads and media. Our new products provide data acquisition, digital signal processing and data streaming solutions for demanding electronic test and measurement, automatic test equipment and original equipment manufacturers.

What prompted the company’s expansion beyond disk drives?

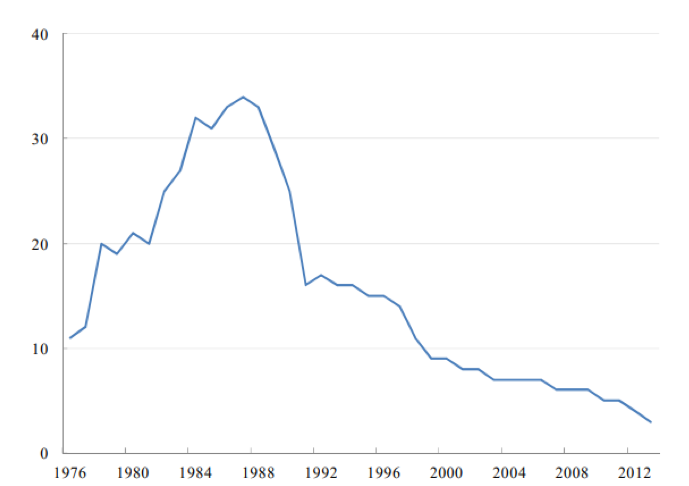

In the 80s there were 30+ hard disk drive (HDD) manufacturers and all claimed they would have 50 percent of the market. However, after the past three decades, only three remain: Toshiba, Western Digital and Seagate. There is general demand to use digitizers with high speed processing in other applications, and that is what prompted the expansion.

What products does Guzik offer today, and what makes them stand out?

While we mainly create innovative products for the HDD industry, like for emerging heat-assisted magnetic recording (HAMR), we are also looking at validation and test challenges in other disciplines. Our focus is GPU- and FPGA-accelerated wideband measurements, and we have successfully demonstrated the ability to more than double the 5G NR and next-gen 60 GHz wideband Wi-Fi signal analysis throughput.

And this is not all: the same precision required for 5G is also in high demand in medical imaging, aerospace and defense and satellite applications, to name a few.

Tell us what market trends are providing your biggest opportunities.

Our core competency is real-time digital signal processing. We apply it to high speed digital-to-analog and interleaved analog-to-digital converters to improve the conversion quality and reduce noise. The focus is to do the analysis in the GPUs and/or FPGAs.

You have an impressive collection of patents. Are they the backbone of your strategy?

If you look at the patent portfolio, you will notice that more than half of them are specific and related to HDD component testers and testing in electronics, mechanics and signal processing algorithms. They are the backbone of our products.

Discuss your approach to the supply chain and how you establish relationships to obtain high performance components not commercially available.

There was a demand in HDD testing for an all-digital receiver that would read back a track from the HDD once and apply many different parametric measurements and algorithms to it in real-time. The only way to do this was with high performance converters, and the only way to get access to such converter technology was to partner with LeCroy, Tektronix and HP/Agilent/Keysight, which we did. We have had exclusive access to HP/Agilent/Keysight components for more than a decade now but have built digitizers with proprietary high speed converters and FPGAs since 1997.

What additional capabilities would you like from your suppliers to really enhance the performance of your products?

We now see an industry-wide push for direct RF, both for capturing and playing back signals. Massively parallel computation is the only means to crunch the data flow from the converters and keep up with the processing.

In addition to the processing, we are also focusing on optics as the means to move data between instruments, and we have started the effort to standardize 850 nm VCSEL interfaces as an AXIe ODI-1 standard.

We are also looking at future memory technologies like HBM2 and next-generation DDR5 to fulfill the real-time write/read requirement and to do real-time FIFO buffering for streaming.

What is your long-term ambition for Guzik, and what are the main challenges facing you?

Our main focus is the HDD industry. At the same time, we are aggressively offering the hardware processing platform developed for HDD component test in other applications where high-speed processing is essential to provide measurement speed.

Tell us about your background and how you ended up at Guzik in this role.

I am from a resort town Pärnu in southwest Estonia, from a family of medical doctors. Early in my life, I chose electronics as my path, instead of medicine. My friends used to call me “born in the midst of wires.”

For my sixth birthday, I asked my mom for a soldering iron with a fine tip, because the surface-mount electronic components were getting smaller, and it was becoming quite tough to solder them with a large Soviet-era iron.

When I graduated high school and, shortly after, moved to the United States, I attended Lincoln University. Before graduating from the university, on the dean’s list and object-oriented programming degree in my hand, I was seeking a hardware engineering internship opportunity. I failed the first interview at Guzik and was sent home to read the thousand page book “The Art of Electronics.”

I returned in a month and was taken in. I gained access to everything they had at the company and would soon begin questioning the company’s design and production practices, while exposing flaws in the processes. It took years to redesign and streamline all of the PCBs and processes, focusing on design for manufacturing.

In general, I picked up electronics professionally and did whatever was needed at the company, from packing finished products in shipping to sweeping the floors — it didn’t matter to me. When I lacked the knowledge, I learned. It took me six years to rise from an intern to the director of production for the whole company.

Now, I manage new ventures at Guzik Technical Enterprises, sponsored by Guzik’s founder Nahum Guzik, to develop solutions for the general purpose test and measurement market.

In addition to your profession, what do you enjoy doing to relax?

New ventures require constant attention, as is the case with start-up founders and internal start-ups like this one. I chose my hobby as my career path, so I am busy thinking of “what next” when not busy in engineering, where I spend 90 percent of my time at work. Technology moves fast, so one really can’t take extended breaks. A company without R&D has no future.

To relax for me means to fly somewhere with my wife and four-year-old son. We love Kauai, so we try to go there when time permits or visit family in Estonia.