Radar and communications designers are continuously challenged to strike the optimal balance of size, weight and power profiles for their unique radar system designs, from military applications spanning ground/air surveillance and target tracking, to civilian radar systems including air traffic control and weather observation. The ever exacting performance, reliability and ruggedization requirements associated with this new generation of mobile radar systems are straining the limits of conventional Si- and GaAs-based power transistor components. The challenge facing radar system designers – accommodating higher power with smaller components – is accelerating the pace of innovation in power transistor packaging technology. But with each incremental gain in component power density, the resulting thermal management issues grow increasingly problematic.

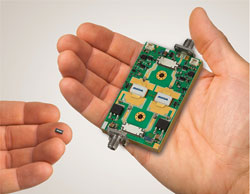

Figure 1 Size comparison of plastic vs. ceramic packaging.

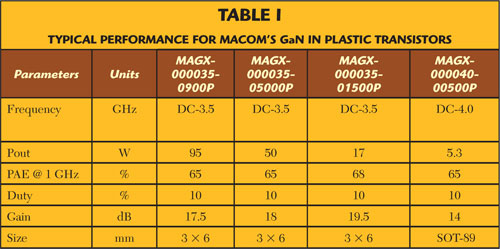

Indentifying these system requirements early, M/A-COM Technology Solutions Inc. (MACOM), introduced its GaN in plastic packaged power transistors for high-performance civilian and military radar and communications systems. The first entries in MACOM’s GaN in plastic power transistor product portfolio include 90 W (MAGX-000035-0900P), 50 W (MAGX-000035-05000P) and 15 W (MAGX-000035-01500P) transistors, all of which are available in standard 3 × 6 mm dual-flat no leads (DFN) packaging. The devices can be mounted on PCBs via ground/thermal arrays. Internal stress buffers allow the devices to be reliably operated at up to 200°C channel temperature. The GaN in plastic series also includes a 5 W device in an even smaller SOT-89 package, measuring 2.5 × 4.5 mm. All of these transistors are capable of operating at frequencies up to at least 3.5 GHz. Table 1 shows a summary of the GaN in plastic devices and key performance data.

Scaling to peak pulse power levels of 100 W, MACOM’s GaN in plastic transistors exceed the power, size and weight limitations of competing ceramic-packaged offerings to enable a new generation of high performance, ultra compact military and civilian radar systems (see Figure 1). As a result, customers can use these products to provide new capabilities and take advantage of the total system cost reductions associated with size, weight and cooling requirements. MACOM’s GaN in plastic builds on the company’s 60+ years of packaging innovation, and rich heritage of expert engineer-to-engineer customer support, ensuring that radar system designers are best equipped to harness the highest power in the smallest possible size.

Packaged in miniature 3 × 6 mm DFN and standard small outline transistor (SOT-89) packages, MACOM’s GaN in plastic transistors operate at 50 V drain bias resulting in outstanding power density and performance, higher efficiency, and smaller impedance matching circuits due to improved device parasitics. The high voltage operation also benefits overall system design with smaller energy storage capacitors and lower current draw.

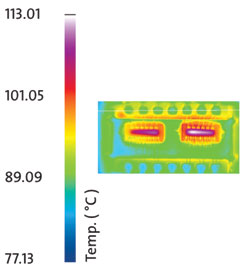

To achieve this new standard, MACOM leverages over six decades of radar design experience to pioneer sophisticated, proprietary thermal dissipation techniques to ensure that its GaN in plastic power amplifiers offer comparable reliability to conventional ceramic-packaged GaN-based offerings. MACOM’s approach optimizes the transistor die layout and uses advanced heat sinking and die attachment methods. Utilizing some of the most stringent thermal imaging testing methodologies in the industry, the 90 W transistor demonstrates less than 115°C junction temperature (80°C baseplate) for a pulsed power output of 93 W, using a 100 µS pulse, 10 percent duty cycle on standard Rogers board material (see Figure 2).

Figure 2 93 W output power shows 113°C junction temperature.

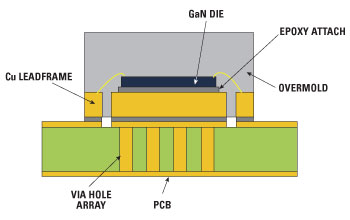

Figure 3 MACOM's plastic packaging construction.

MACOM’s GaN in plastic-based power transistors are also lightweight compared to the existing ceramic-packaged GaN-based offerings. Measured in aggregate across the hundreds of power amplifiers within a typical modern radar system, this can reduce overall system weight considerably. The resulting weight reduction ensures greater ease of movement for mobile radar systems.

MACOM’s high performing GaN in space saving plastic enables radar system designers to take full advantage of GaN technology and achieve new levels of power density while reducing system size and weight significantly. Utilizing sophisticated packaging (see Figure 3) and thermal management techniques to maximize design efficiency and component reliability, MACOM is working hand-in-hand with designers to overcome challenging development hurdles and pioneer a new generation of high-performance, rugged radar systems that transcend the capabilities of systems based on conventional GaN in ceramic packages. GaN in plastic test fixtures are available and datasheet are available online.

MACOM,

Chelmsford, MA,

www.macomtech.com/gan