Test and measurement is a crucial application where cable assembly innovations like those introduced by Junkosha over the years are constantly required. As we move toward a 5G-enabled and in the coming years a 6G-enabled world, the cables and interconnects used in test and measurement processes must be of the highest standard and reliability.

5G represents the next major evolution of mobile communication technology and it is enabling next-generation applications such as the IoT, autonomous vehicles and virtual reality. The evolution to 5G brings significant hurdles that must be overcome. For example, frequency spectrum availability is limited and 5G operators are looking at even higher frequencies to deliver faster data speeds.

Advances in 5G have created interest in higher mmWave frequencies where cabling and interconnect solutions must be robust to withstand the rigor they are subjected to in many applications. These applications may be in the system development or device performance characterization phases where precision and repeatability are required, or in the stages of commissioning the overall system and monitoring performance in the production test environment.

Cabling assemblies deployed in a test environment are often utilized with vector network analyzers (VNAs). These analyzers are used to test and characterize individual components or a network composed of many components to ensure systems function properly together. At mmWave wavelengths, instances of flexure and mechanical stress have a significant impact on the accuracy of the results, which is accentuated as frequencies increase.

Accuracy is crucial in any test setting, but particularly so for metrology-grade cabling. These applications demand the ultimate precision and the highest reliability for testing and calibration purposes. In response, Junkosha has been showcasing its 8 Series VNA Test Assembly over the last 12 months. The 8 Series is designed as a high-quality metrology-grade VNA test cable for users requiring optimum precision.

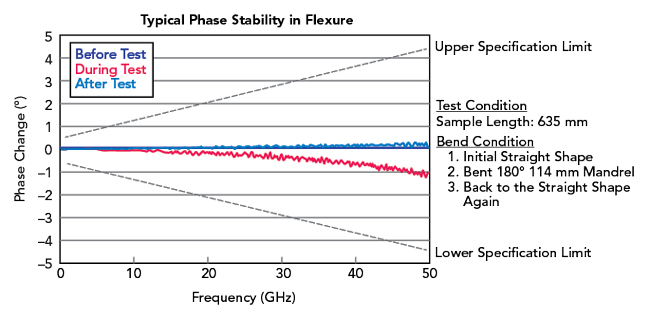

Utilizing Junkosha’s precision-engineered expanded-PTFE tape-wrapping technology, a 25-in. long metrology-grade cable exhibits phase stability within ± 1.5 degrees at 50 GHz and amplitude stability within ± 0.08 dB at 50 GHz in flexure. Figure 1 shows a graph of phase stability in flexure for this metrology-grade cable. The cable is flexible and can maintain this level of performance when bent 180 degrees on a 2.25-in. radius mandrel, with no spring back. Able to reach 50 GHz and available in a 2.4 mm connector, the assembly typically achieves 50,000 tick-tock cycles. The ruggedized port side NMD connector is also available to ensure reliable connections to the VNA.

Figure 1 Phase stability versus frequency for flexure.

A key application area for this metrology-grade microwave/mmWave VNA test cable assembly is in measuring the device under test when designing a high frequency component. This metrology-grade cable can also be used for coaxial cable, components and device development. Offering a calibration level standard bench test, target customers for this solution include national institutes, calibration laboratories and service providers who value repeatability.

Both 26.5 and 50 GHz versions of the 8 Series VNA Test Assembly are available with NMD-style ruggedized connectors for direct attachment to VNA test ports. Other iterations are available on demand. It can be shipped along with the VNA or as part of an aftersales package to replace an existing cable.

As 5G evolves, humans and devices will require more wireless connectivity to enable a connected world that will rely on innovation to create more efficient use of the available frequency spectrum. The demand for mmWave frequencies has gone from the domain of the few to the requirement of the many, thanks to varied new space and defense applications to emerging high volume commercial applications. To enable the required system performance at higher mmWave frequencies, “phase performance that endures” is a statement that the cable and interconnect ecosystem must live up to, especially in the test and measurement environment. Junkosha’s latest solutions provide VNA manufacturers with the capability to test the high frequency networks that are at the heart of tomorrow’s highly sophisticated systems.

In addition to the 8 Series, Junkosha has launched the MWX7 Series of cables within the past 12 months. This is another in the range of high-end mmWave cabling solutions. The ePTFE tape-wrapped, phase-stable MWX7 Series of cables deliver excellent phase and amplitude stability against temperature fluctuations for multiple applications. The cables offer reduced phase and amplitude drift due to mechanical fluctuations to support repeatable results. Junkosha’s in-house manufactured dielectric ePTFE tape-wrapping technology promises consistent performance in both inter- and intra-batch quality to maintain peak performance.

Junkosha

Irvine, Calif.

www.junkosha.com/en/products/cable