Types of Absorbers

There are two basic types of Absorbers. The first type is dielectric, in which the absorbing filler acts on the electric field. The most common of this type are carbon and silicon carbide, which can be impregnated into polyurethane foams or rubber materials. The second type is magnetic, in which absorbing fillers, such as carbonyl iron, act on the magnetic field. There are many varieties of RF absorbers; your application determines the one required. The most important characteristics of absorbers are insertion loss, reflectivity, and attenuation.

Absorber materials are altered so that they can absorb microwaves and possibly heat. The following lists the most common types of absorbers. In later blogs, we'll discuss some of these in more detail. For now, it's enough to know that there are a variety of absorber materials and applications available.

- rubber sheet microwave absorbers

- carbon-based foam microwave absorbers

- anechoic chamber materials

- honeycomb & high-power microwave absorbers

- low loss dielectric stock materials

- sprayable microwave absorbers

- radomes and radar-absorbing structures

- rigid and castable microwave absorbers

- adhesives

Attenuation

Any discussion about absorbers is incomplete without including attenuation. In everyday life, we don't usually include the word. We don't say that sunglasses attenuate the bright light of the sun. We don't say that a jacket attenuates the cold when we are outside. But both of those statements are true.

In the world of RF microwaves, attenuation is the reduction of the amplitude of signals, electric currents, or other waves. Microwave absorbers are filled with materials such that as a microwave strikes them, the waves become attenuated and loses energy. The energy loss is due to a conversion from EMI energy to heat energy via phase cancellation. The amount of attenuation of the microwave depends on the frequency, the electrical permittivity, and magnetic permeability of the material.

Application of Absorbers

Absorbers have long been used in military applications. Over time, commercial applications have made use of microwave absorbers as well. Computers, consumer electronics, network servers, and wireless antenna systems all use microwave absorbers. The demand for absorbers only seems to increase. And over time, the types of materials used as absorbers have expanded as well.

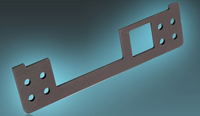

Laser-cutting vs. Die-cutting

There are several different ways to cut absorber materials. Among those methods are laser-cutting and die-cutting. Laser-cutting offers the following benefits:

- Laser-cutting does not require any tooling; this reduces your costs.

- Laser-cutting reduces material cost by prioritizing part orientation and therefore maximizes use of the available material.

- Laser-cutting is consistently reliable because each laser-cut during a run references the same electronic file.

- Laser-cutting has tighter, more repeatable tolerances than die-cutting can achieve.

Absorbers from prototype to production

Our process begins with calling upon our expertise to review and validate absorber materials for lasering manufacturability and performance. We routinely manage small, prototype qualification runs through to high-volume, high-quality production runs.

We pride ourselves on staying at the forefront of microwave absorber technology. We have acquired deep microwave absorber technology expertise over the years and rely upon this experience when laser machining a variety of different materials. We understand the way different materials react to the lasering process and we can share this information with our clients to help overcome the unique design challenges our customers face.

Accumet has 28 different automated laser systems operating on the manufacturing floor. We have the right equipment for the job and can accommodate flexible production run sizes and short lead times. We routinely laser ECCOSORB® material, silicone rubber, pressboard kits, or any other material used in common RF assemblies with or without adhesive.