Groundbreaking technology is needed to solve big problems: microelectromechanical system (MEMS) switches can deliver the innovation needed to overtake relays and let the industry achieve the next level of performance. Relays date to the earliest days of the electric telegraph, and, until now, no alternative switching technology has been developed that can meet all the evolving market needs in test and measurement (T&M), communications, defense, healthcare and consumer. As one example, T&M users are demanding multi-standard test solutions in the smallest form factor, with maximum parallelism and DC to 10s of GHz coverage. Mapped against this requirement, electromechanical relays have narrow bandwidths, a limited number of channels and large package sizes — plus limited actuation lifetimes.

With an internal state-of-the-art MEMS fabrication facility, Analog Devices (ADI) is now mass producing MEMS switches that are high performance, small, fast, low power, mechanically durable and electrostatic discharge (ESD) protected. Initially, two catalog products are available: the ADGM1004 is a SP4T switch covering 0 Hz (DC) to 13 GHz with enhanced ESD protection: 5 kV human body model (HBM) on the RF ports — a MEMS switch industry first. The ADGM1004 integrates solid-state ESD protection technology to increase the ESD rating. The second switch, the ADGM1304, offers similar RF performance; however, it does not include the added solid-state ESD protection technology and is rated at 100 V HBM.

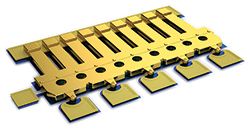

Figure 1 Single MEMS cantilever switch beam.

MEMS SWITCH TECHNOLOGY

Central to the ADI MEMS switch technology is an electrostatically-actuated micro-machined gold cantilever beam switching element. The switch can be thought of as a micrometer-scale mechanical relay, with metal-to-metal contacts that are actuated through high DC voltage electrostatics. Figure 1 is a graphic of a single MEMS switch cantilever, showing the five parallel contacts in the front and the hinge structure with air gaps in the rear.

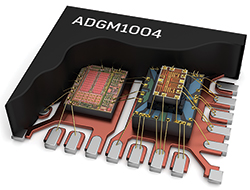

A companion driver IC, designed by ADI, makes the MEMS switch easy to use. It generates the high DC voltage required to actuate the switch, ensuring fast and reliable actuation and long switching lifetime. The driver typically consumes only 10 mW, which is 10× lower than typical drivers used for RF relays. The MEMS die and driver IC are assembled in an ultra-small SMD QFN package.

Figure 2 MEMS switch with ESD protection (right) and driver IC (left) assembled in QFN package.

Figure 3 Solid-state ESD protection die mounted on the MEMS switch.

The ADGM1004 version of the MEMS switch also integrates solid-state ESD protection technology (see Figure 2), which increases the RF port ESD rating to 5 kV (HBM). The non-RF ports are rated at 2.5 kV (HBM). The integrated solid-state ESD protection circuitry is a proprietary ADI technology that provides protection with minimal effect on RF performance. Figure 3 shows the ESD protection die, which is mounted on the MEMS die in the package. The wire bonds to the RF pins of the package are optimized for both RF and ESD performance. To develop the ADGM1004, ADI combined three proprietary lithographic technologies with assembly and a MEMS capping technology to achieve this breakthrough HBM ESD rating.

Figure 4 Insertion loss and isolation of the MEMS switch.

0 Hz TO 13 GHz PERFORMANCE

The strength of the MEMS switch is that it combines DC precision and wideband RF performance in a 5 mm × 4 mm × 1.45 mm, surface-mountable form factor. Figure 4 shows the measured insertion loss and off isolation for the ADGM1004 SP4T switch. Insertion loss is only 0.45 dB at 2.5 GHz, and the 3 dB bandwidth reaches 13 GHz. RF power handling is rated at 32 dBm without compression, and the third-order intercept point (IP3) is typically a constant 67 dBm vs. frequency, with no degradation at very low frequencies. Switching speed is 30 μs. On resistance is typically 1.8 Ω, off leakage current is a maximum of 0.5 nA, and the switch will pass ±6 V and 220 mA. The switch requires a supply voltage between 3.1 and 3.3 V and consumes 10 mW typical.

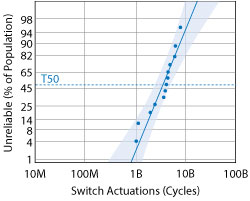

The actuation lifetime of the ADGM1004 switch has also been characterized by toggling the switch with RF power passing through it (i.e., hot switching). Figure 5 shows the projected lifetime probability distribution when hot switching a 2 GHz, 10 dBm RF signal. From this test, the mean number of cycles before failure (designated T50) is approximately 3.4 billion cycles. The ADGM1004 data sheet provides data for higher power levels. ADI specifies a cold switch lifetime of 1 billion cycles minimum.

Figure 5 10 dBm hot switch mean lifetime is approximately 3.4 billion cycles.

CONCLUSION

ADI’s groundbreaking MEMS switches are easy to use and provide excellent switch performance in RF and 0 Hz applications. With footprint an increasingly critical requirement across all markets, a MEMS switch occupies up to 95 percent less volume than a typical DPDT electromechanical relay. ADI’s MEMS technology consumes 10× less power, is 10× more reliable and 30× faster than relays. The ADGM1004 provides enhanced ESD protection, with a rating of 5 kV HBM on all RF ports.

Analog Devices Inc.

Norwood, Mass.

www.analog.com