Today, the 3D waveguide antenna metallized plastic technology, first introduced by HUBER+SUHNER more than a decade ago, plays an integral role in several industries, particularly in automotive radar for advanced driving systems. This article provides insight into the technology and products and how the products meet the technical demands of the automotive industry. The article recounts on the technology journey from antennas for mmWave backhaul through fixed wireless communications to automotive radar, establishing HUBER+SUHNER as a 3D metallized plastic antenna supplier.

In the search for highly efficient and compact radiators that can be produced at an attractive manufacturing cost, engineers at HUBER+SUHNER have worked on metallized plastic technology since the early 2000s. Through multiple innovation steps, lightweight 3D waveguide antennas with compact form factors have been successfully designed, manufactured and validated.

Thanks to improved efficiency, pattern stability and large bandwidth, these products are becoming increasingly sought after in the automotive world. This work reviews the journey HUBER+SUHNER has taken to become the supplier of 3D radar waveguide antennas.1,2

THE ORIGIN: mmWAVE BACKHAUL

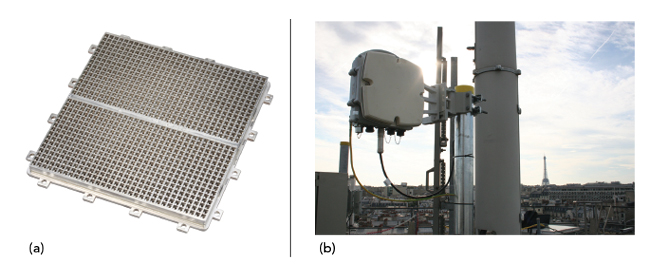

The first 3D waveguide metallized plastic antennas (see Figure 1) were designed by HUBER+SUHNER and have been manufactured there since 2006.3,4 These products provide high gain and small form factor for mmWave backhaul at V- and E-Bands (57 to 66 GHz and 71 to 86 GHz, respectively) while remaining compliant with international regulations.5

Figure 1 HUBER+SUHNER mmWave backhaul antennas: 38 dBi (a) and 43 dBi (b).

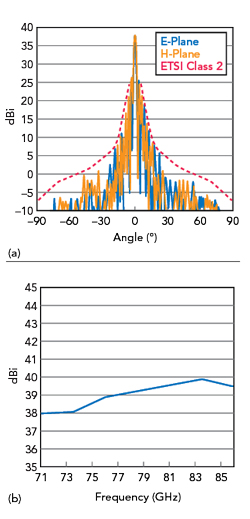

For this purpose, several designs incorporating 1024 to 4096 radiators are fed with the same amplitude and phase and are combined into a single input. This approach results in a radiation pattern with a very focused pencil beam (directivity ranging from 38 to 43 dBi, respectively), controlled sidelobe levels and stable gain over frequency (see Figure 2).

Figure 2 HUBER+SUHNER mmWave backhaul antennas measured radiation pattern at 73.5 GHz (a) and boresight gain over frequency (b).

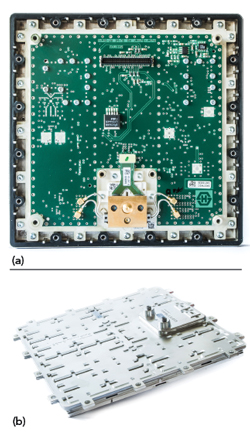

Figure 3 SL60 RF front-end (a) and integrated V-Band antenna-diplexer (b).

Figure 4 Terragraph RF front-end board. Two antennas were used for transmitting (Tx) and receiving (Rx), respectively.

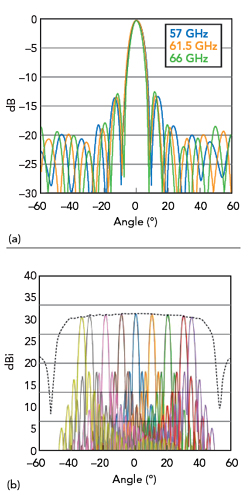

Figure 5 36-channel antenna module normalized elevation pattern vs. frequency (a) and azimuth beam steering at 61.5 GHz (b).

Filters and diplexers with high Q factors were also built with the same technology. This led to further advantages, including compact mechanical housing and fixation concepts which enabled the realization of a fully integrated point-to-point mmWave radio backhaul system, the ‘SL60’ (see Figure 3a).3 A more recent version of the V-Band antenna and the diplexer combination is shown in Figure 3b.

SOLVING THE URBAN BANDWIDTH CHALLENGE

The next phase of the metallized plastic antenna evolution occurred with the shift from point-to-point links to multipoint-to-multipoint wireless distribution network applications within the Terragraph6 program. This project seeks to provide more people with access to fast internet, deploying gigabit connectivity quicker and more efficiently in markets where fiber trenching is expensive. The solution developed by HUBER+SUHNER, given its broadband characteristic covering the frequency spectrum from 57 to 66 GHz, formed the backbone of the first technology demonstrators for sustained, reliable connectivity (see Figure 4).

THE MULTI-CHANNEL EVOLUTION

The multipoint-to-multipoint wireless distribution network called for HUBER+SUHNER metallized plastic antennas to evolve from single to multi-channel; a 36-input antenna with vertical polarization was designed and manufactured.

The combined use of all channels makes it possible to steer the main radiation beam to point the communication link to where it is most needed. Figure 5 shows how full coverage over ±35 degrees in the horizontal plane is achieved while maintaining a realized gain above 29 dBi.