Company Profile

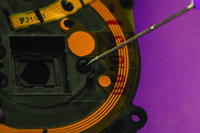

Master Bond formulates innovative, high quality epoxy adhesives, sealants, coatings and potting/encapsulation compounds for the RF and microwave industries. Each system is designed to meet specific application needs and requirements where electrical performance is critical. Compounds are formulated to be electrically conductive, thermally conductive and electrically insulative as needed. We also have formulations for effective shielding for EMI/RFI applications.

As the miniaturization of electronic devices expands, heat transfer capabilities become increasingly important. Master Bond adhesives offer superior heat transfer properties and low coefficient of thermal expansion for use in applications related to the microwave and RF industries.

Certain products include fillers (such as graphite, nickel and silver) which are used to enhance a variety of performance properties including non-magnetic properties, electrical conductivity, EMI/RFI shielding, electro static discharge (ESD), resistance to thermal cycling, low stress, low volume resistivity and more.

Established in 1976, today Master Bond formulates over 3,000 grades of epoxies, silicones, UV cures and other specialty adhesive systems. We offer a variety of standard and specialty packaging solutions to best meet your specific application. Our technical staff, with years of experience, will provide individual service to determine the best adhesive for your application.

Contact Information:

Location:

Downloads

Adhesives, Sealants & Coatings for the Electronic Industry

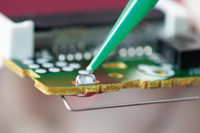

Master Bond Inc. is a leading manufacturer of adhesives, sealants, coatings, potting and encapsulation compounds. We off er an extensive product line consisting of epoxies, silicones, light curing compounds, polysulfi des and other polymer systems for the electronic industry.

DownloadThermally Conductive Adhesives Keep Things Cool

Thermally conductive adhesives and potting compounds are an important weapon in the war against heat raging within today’s powerful electronic devices. Master Bond’s line-up of thermal interface materials includes one- and two-component epoxies as well as silicones and solvent-based compounds.

Download

Supreme 12AOHT-LO is a toughened system with superior resistance to aggressive thermal cycling and shock. Cryogenically serviceable, it combines superior thermal conductivity with reliable electrical insulation properties. This dimensionally stable epoxy has formidable bond strength, particularly in the shear mode, ranging from 3,400-3,600 psi. Its service temperature range extends from 4K to +260°C.

Supreme 12AOHT-LO is a toughened system with superior resistance to aggressive thermal cycling and shock. Cryogenically serviceable, it combines superior thermal conductivity with reliable electrical insulation properties. This dimensionally stable epoxy has formidable bond strength, particularly in the shear mode, ranging from 3,400-3,600 psi. Its service temperature range extends from 4K to +260°C.  Featuring a low viscosity, EP38CL is an optically clear two component epoxy that is used for bonding, sealing, coating and encapsulation in optical, aerospace, opto-electronic and specialty OEM applications. It possesses superior impact resistance, thermal cycling capabilities as well as the ability to withstand mechanical shock better than typical epoxies that are higher on the Shore D scale.

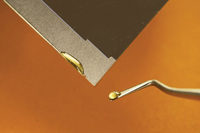

Featuring a low viscosity, EP38CL is an optically clear two component epoxy that is used for bonding, sealing, coating and encapsulation in optical, aerospace, opto-electronic and specialty OEM applications. It possesses superior impact resistance, thermal cycling capabilities as well as the ability to withstand mechanical shock better than typical epoxies that are higher on the Shore D scale.  Specially formulated, two part epoxy EP48TC has ultra low thermal resistance of 5 to 7 x 10 to 6 K•m2/W. This system uses high thermal conductive fillers and is capable of being applied in bond lines as thin as 10-15 microns. It also features unmatched thermal conductivity of 20-25 BTU•in/ft2•hr•°F [2.88-3.60 W/(m•K)]. EP48TC has first rate electrical insulation properties over the wide service temperature range from -100°F to +300°F.

Specially formulated, two part epoxy EP48TC has ultra low thermal resistance of 5 to 7 x 10 to 6 K•m2/W. This system uses high thermal conductive fillers and is capable of being applied in bond lines as thin as 10-15 microns. It also features unmatched thermal conductivity of 20-25 BTU•in/ft2•hr•°F [2.88-3.60 W/(m•K)]. EP48TC has first rate electrical insulation properties over the wide service temperature range from -100°F to +300°F.  With exceptional thermal conductivity and electrical insulation properties, EP46HT-1AO is a two component epoxy for high performance bonding and sealing applications. This high temperature resistant system cures readily with heat and offers a long open time at room temperatures. It provides noteworthy dimensional stability, chemical resistance and physical strength properties.

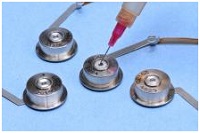

With exceptional thermal conductivity and electrical insulation properties, EP46HT-1AO is a two component epoxy for high performance bonding and sealing applications. This high temperature resistant system cures readily with heat and offers a long open time at room temperatures. It provides noteworthy dimensional stability, chemical resistance and physical strength properties.  Master Bond’s epoxy EP79FL is a silver coated nickel filled polymer system that forms high strength bonds even at extreme cryogenic temperatures. It is electrically conductive and has minimal sagging while maintaining thermal cycling resistance. EP79FL is a strong and flexible system with exceptional chemical resistance properties. The electronic, electric, computer, semiconductor, microwave, appliance and automotive industries use it extensively.

Master Bond’s epoxy EP79FL is a silver coated nickel filled polymer system that forms high strength bonds even at extreme cryogenic temperatures. It is electrically conductive and has minimal sagging while maintaining thermal cycling resistance. EP79FL is a strong and flexible system with exceptional chemical resistance properties. The electronic, electric, computer, semiconductor, microwave, appliance and automotive industries use it extensively.  One component Master Bond MasterSil 711 is a room temperature curing silicone compound for bonding, sealing, coatings and formed-in-place gaskets. It offers superior shock and impact resistance making it ideal for delicate electronic components. Flexible bonds are formed when exposed to atmospheric moisture. MasterSil 711 requires no mixing or heat, and sets within 2-3 minutes.

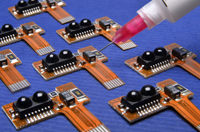

One component Master Bond MasterSil 711 is a room temperature curing silicone compound for bonding, sealing, coatings and formed-in-place gaskets. It offers superior shock and impact resistance making it ideal for delicate electronic components. Flexible bonds are formed when exposed to atmospheric moisture. MasterSil 711 requires no mixing or heat, and sets within 2-3 minutes.  Well suited for die attach applications, Supreme 3HTND-2DA is a single component fast setting epoxy that doesn’t require mixing or freezing. This toughened system has high die shear strength, superior electrical insulation properties, low ionics, an ideal dispensing profile (no tailing or bleed out) and performs well in 85/85 testing. It also passes NASA low outgassing tests.

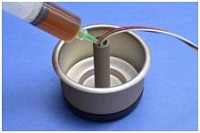

Well suited for die attach applications, Supreme 3HTND-2DA is a single component fast setting epoxy that doesn’t require mixing or freezing. This toughened system has high die shear strength, superior electrical insulation properties, low ionics, an ideal dispensing profile (no tailing or bleed out) and performs well in 85/85 testing. It also passes NASA low outgassing tests.  Suitable for large castings, EP21LVSP6 is a room temperature curing system with a long open time and a low viscosity. This epoxy features a convenient one to one mix ratio and can also be used in bonding, sealing and coating applications. It has very good physical strength properties as well as being an excellent electrical insulator.

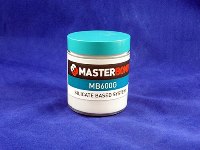

Suitable for large castings, EP21LVSP6 is a room temperature curing system with a long open time and a low viscosity. This epoxy features a convenient one to one mix ratio and can also be used in bonding, sealing and coating applications. It has very good physical strength properties as well as being an excellent electrical insulator.  Master Bond MB600S is an aqueous based sodium silicate coating formulated for applications where electromagnetic interference/radio frequency interference (EMI/RFI) shielding is required.Tested according to IEEE 299, 2006 methods, MB600S was as effective as the aluminum reference with a shielding effectiveness of 95 to105 dB, from 1 to 2 GHz.

Master Bond MB600S is an aqueous based sodium silicate coating formulated for applications where electromagnetic interference/radio frequency interference (EMI/RFI) shielding is required.Tested according to IEEE 299, 2006 methods, MB600S was as effective as the aluminum reference with a shielding effectiveness of 95 to105 dB, from 1 to 2 GHz. Ideal for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding applications, MB600G is an aqueous based, sodium silicate system with a graphite filler. Electrically conductive, graphite filled materials are widely used for shielding and static dissipation applications because of their balance of shielding effectiveness and cost effectiveness.

Ideal for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding applications, MB600G is an aqueous based, sodium silicate system with a graphite filler. Electrically conductive, graphite filled materials are widely used for shielding and static dissipation applications because of their balance of shielding effectiveness and cost effectiveness.