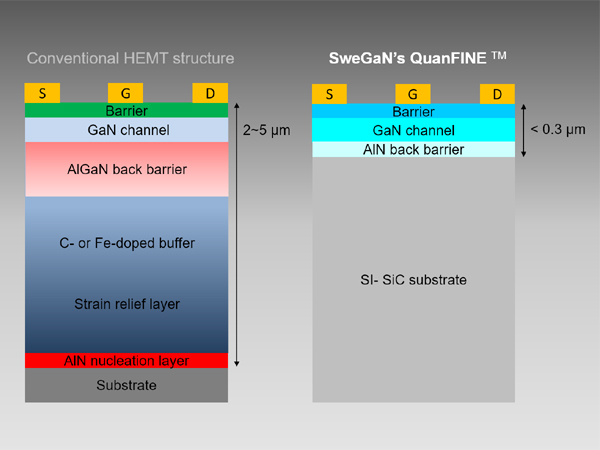

SweGaN is a spin-off from Linköping University that recently announced a new GaN-on-SiC HEMT heterostructure, QuanFINE ™, built on the concept of a GaN−SiC hybrid material that combines the high-electron-velocity thin GaN with the high-breakdown bulk SiC. According to their web site, the structure is realized by the company’s unique hot-wall MOCVD process and shown good result in both high-frequency and power transistors. For high-frequency applications, QuanFINE™ features a buffer-free HEMT heterostructure, where the AlN nucleation layer serves effectively as a back-side barrier. Therefore, the electrons in the thin GaN channel (<250 nm) are well confined in the quantum-well–like structure by the front-side and back-side barriers.

For power applications, QuanFINE™ utilizes the semi-insulating SiC substrate as the voltage blocking layer, the quality and resistivity of which is significantly higher than the conventional thick carbon-doped GaN buffer layer. It also offers the best thermal management by using a thin layer directly on the SiC so there is a shorter thermal path to the high thermal conductivity SiC. They recently published the details in Applied Physics Letters together with scientists at Chalmers University of Technology and Linköping University - https://doi.org/10.1063/1.5042049.

The company also says that using their proprietary high-mobility growth process, the channel electron mobility >2000 cm2/V-s and >1800 cm2/V-s can be achieved in the epi wafers with AlGaN/GaN and InAlN/AlN/GaN heterostructures, respectively, which is 20 to 30% higher than the conventional channel electron mobility. Typically, the channel heterojunction is atomically abrupt. The surface morphology of the HEMT heterostructures exhibit a low roughness of 0.2 nm and contains limited pits/defects. The record-high mobility enables higher efficiency and higher operation frequency of the transistors. GaN and AlN epitaxial layers grown by SweGaN’s high-temperature process exhibit excellent structural quality. The threading dislocation density in the GaN layer is typically in low 108 cm-2 range and the AlN nucleation layer is free of grain boundaries. This is the best structural quality in its class, which not only guarantees the GaN robustness but also dramatically reduces the risk of device failure due to the structural defects.

Also noted in their materials, the conventional Thermal Boundary Resistance (TBR) in the GaN/SiC interface causes up to 40% of additional channel temperature rise in transistors. Using their ultra-low-TBR AlN nucleation layer, they have been able to reduce to a very low level. The structural quality of the thin AlN nucleation layer significantly improves the heat transport from the channel down to the high-thermal-conductivity SiC substrate. This allows them to improve reliability - they note that by reducing the operational temperature by 25 °C, the device lifetime is increased by a factor of 10.

The company currently offers up to 4” wafers, characterization services, R&D assistance and device processing in conjunction with their partners. It will be interesting to follow them over the next couple of years to see if the market accepts this new GaN structure for wide use in the RF industry.