Recently, many types of wireless communication systems have rapidly developed and the demand for bandwidth has increased. The spread spectrum communication systems, such as the code division multiple access (CDMA) systems have attracted increasing attention because of their unique features that make it possible to transmit signals through noisy communication channels with a high degree of security. Therefore, high-performance microwave devices having low insertion loss and wide bandwidth are required.

The filter is an important component for radio frequency integrated circuits (RFIC) in wireless communication systems and used in both receivers and transmitters. The reduction of filter size has been the focus of several studies. The problems caused by the larger, heavier and discrete conventional filters can be solved by using a planar filter. Many forms of the planar filter exist; therefore, surface acoustic wave (SAW) filters1,2 and microwave microstrip filters3-12 are small, light and simply fabricated. No convenient and low cost resonators for high-frequency applications are better than planar resonators such as microstrip resonators. The microstrip version is the most popular structure of a planar transmission line. Moreover, cross-coupled microstrip filters have attracted much attention in recent years due to their quasi-elliptical function or flat group delay responses. This type of microstrip resonator with appropriately designed circuits, effectively reduces the volume of circuits by using ULSI techniques.

In addition, SAW filters are currently available for mobile and wireless applications in frequency ranges from 800 to 1500 MHz for personal communications services (PCS) and wide area networks (WAN) in a small form factor and can be mass produced by high volume fabrication processes. Generally, some factors can easily increase the insertion loss for conventional SAW filters such as bi-directional loss, electrical mismatch loss, propagation loss in the substrate, bulk wave problems, parasitic resistance of an interdigital transducer (IDT), and scatter capacitance of the delay line.13 The insertion loss usually exceeds 6 dB (3 dB per transducer).14 The central frequency of a conventional SAW filter is determined by the width of the IDT finger and the phase velocity that excites the SAW on the piezoelectric materials (Vs = λoƒo, where Vs is the phase velocity of the acoustic wave, λo is the wavelength of the acoustic wave and ƒo is the central frequency of the SAW filter).15 For gigahertz range applications, it is necessary to develop new high velocity SAW materials or use a process with submicron design-rules. The width of the designed IDT finger must be less than 1 micron to yield a working high frequency device in the gigahertz range. Such a finger is hard to fabricate on a standard piezoelectric material such as the 64°-rotated Y-cut lithium niobate (LiNbO3). Besides, conventional SAW filters generally have a narrow bandwidth, but greater bandwidth is required to meet the demand of communication systems. Generally, bandwidth can be increased by redesigning the IDT circuits,16 but the fabrication becomes more complex and difficult. The high insertion loss and the narrow bandwidth will limit the usage of SAW devices so performance improvement is an important issue.

Fundamental ideas on the usefulness of combining of a SAW and bulk piezoelectric phenomena were already proposed in the last decade, but nobody has tried to design the novel combination circuit of microwave microstrip and SAW interdigital transducers. Moreover, nobody has analyzed the interrelationship between electromagnetic (EM) waves and SAWs. In this article, a novel microwave device including both the four cross-coupled microstrip square open-loop resonators and the SAW filters with 16 micron input/output IDTs of 42 pairs is designed and fabricated using the semiconductor process including photolithography and evaporation on the piezoelectric substrates. The working frequency of this novel filter can be easily increased up to 2.5 GHz without reducing the width of the IDT finger below 1 micron. It is found that this proposed filter has a lower insertion loss and a wider bandwidth due to the interaction between electromagnetic waves and the piezoelectric SAWs, substantially improving the characteristics of the conventional SAW filters. To confirm the SAW is still excited in this proposed device, four cross-coupled microstrip square open-loop resonators without SAW IDTs are designed and fabricated on the same LiNbO3. Moreover, the proposed filter is also fabricated on the non-piezoelectric substrate in order to identify how the piezoelectric effect is affecting the performance. This article will also use the principle of SAW and equivalent circuit of IDT to prove the experimental results. The difference will be obtained by these comparisons to distinguish the contribution of SAW effect.

Experiment

Based on the device specifications and design principles determined by the requirements of the circuit, four cross-coupled microstrip square open-loop resonators and the input/output IDTs of the SAW were designed and fabricated. A detailed fabricating process is shown in a previous report.17 The techniques for fabricating planar microwave devices and SAW devices are similar to ULSI techniques. ULSI technology used in conventional photolithography and the evaporation techniques for metal patterns were used to fabricate novel microstrip SAW devices on the 64°-rotated Y-cut lithium niobate (LiNbO3) piezoelectric material and the non-piezoelectric SiO2/Si material with a thickness of 9000 Å. After the normal cleaning process for these wafers, the conventional photolithography and lift-off techniques were applied for metal pattern fabrication on the two substrates. An aluminum electrode with thickness of 1000 Å was deposited on the substrates by using vacuum evaporation. Due to the addition of the microstrip lines in the microwave SAW filter, the backside of the substrate was covered with the aluminum electrode. The four cross-coupled microstrip square open-loop resonators based on the same specifications were fabricated by the same methods. It requires only one mask step to fabricate this device during the experimental procedure. It is suitable for mass-produce because of its simple processing. The performance of the designed SAW filter was characterized on a HP 8722ET network analyzer.

Results and Discussion

Figure 1 Configuration of a novel microstrip SAW filter.

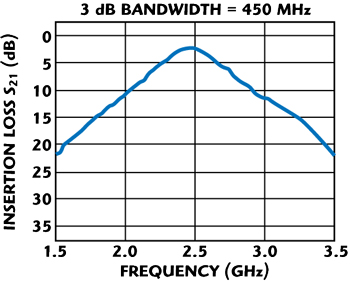

Figure 2 Frequency response of the novel microstrip SAW filter fabricated on LiNbO3 substrate.

Figure 3 A 16 micron IDT conventional SAW filter without a metal ground on the back of the substrate.

Figure 4 Frequency responses of the 16 micron IDT conventional SAW filter fabricated on the LiNbO3 substrate.

Figure 5 Configuration of the four cross-coupled microstrip square open-loop resonators without IDTs.

Figure 6 Frequency response of the four cross-coupled microstrip square open-loop resonators without IDTs on the LiNbO3 substrate.

According to the device design, the microstrip structure with four cross-coupled microstrip square open-loop resonators was combined with a conventional SAW filter using 16 micron input/output IDTs of 42 pairs fabricated on the 64°-rotated Y-cut lithium niobate (LiNbO3) with a higher electromechanical coupling coefficient (K2=11.3 percent). An aluminum layer was also deposited for the ground plane on the back of the substrate. The configuration of the novel microstrip SAW filter is shown in Figure 1 (sample A). Figure 2 shows the frequency response of this device that is a wide-bandwidth and low-loss filter with a central frequency of 2.5 GHz, a 3 dB bandwidth of 450 MHz (BW = 18 percent) and an insertion loss S21 of 2.41 dB. When this novel filter is fabricated on the 64°-rotated Y-cut LiNbO3, the absence of an aluminum metal layer to ground the back of the piezoelectric substrate yields a conventional SAW bandpass filter with the structure shown in Figure 3 (sample B). A central frequency ƒo of 69 MHz, a 3 dB bandwidth of 1 MHz (BW = 1.4 percent), a reflection loss S11 of 20.191 dB and an insertion loss S21 of 3.987 dB are obtained for sample B, as shown in Figure 4. Comparison of the novel microstrip SAW filter and the conventional SAW filter, as shown in Figures 2 and 4, reveals that a central frequency of 69 MHz is increased to 2.50 GHz; an insertion loss of 3.987 dB is reduced to 2.41 dB without adding reflection gratings; and a bandwidth of 1 MHz (BW = 1.4 percent) is increased to 450 MHz (BW = 18 percent). In addition, the configuration of the four cross-coupled microstrip square open-loop resonators is fabricated on the same LiNbO3 without IDTs, as shown in Figure 5 (sample C). Figure 6 shows the performance of sample C that has a central frequency of 2.51 GHz, a 3 dB bandwidth of 320 MHz (BW = 12.7 percent) and an insertion loss S21 of 3.59 dB. From the results of Figures 2 and 6, the variation of the bandwidth and the insertion loss between the novel microstrip SAW filter and the four cross-coupled microstrip square open-loop resonators is observed. The bandwidth of Sample A and Sample C is 450 MHz (18 percent) and 320 MHz (12.7 percent), respectively, and the insertion loss of Sample A and Sample C is 2.41 and 3.59 dB, respectively.

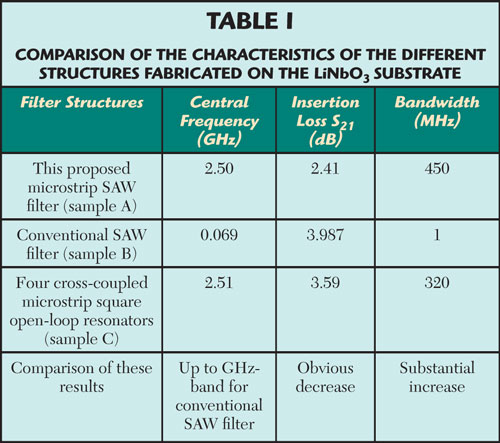

Comparisons of the characteristics of these devices are summarized in Table 1. However, the SAW propagates on the piezoelectric substrate not only due the elastic wave movement in the medium, but also due to the time-dependent electric field and magnetic field effects that are produced on the piezoelectric substrate.18 In the microwave frequency domain, the IDTs of the SAW devices are also regarded as electromagnetic microwave lumped-element devices as well as piezoelectric transducers that operate by two different mechanisms. Therefore, the relationships and interactions between the SAW and EM waves are produced on the piezoelectric substrates for the novel SAW microstrip filters. It is concluded that this microstrip device fabricated on the LiNbO3 substrate is capable of interacting with piezoelectric SAW and acts as a high-performance, low-loss, wide-bandwidth microwave filter.

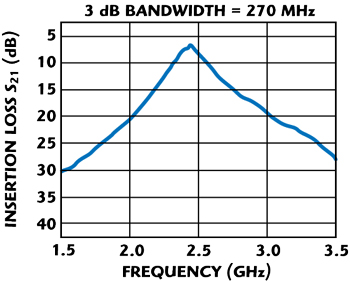

Figure 7 Frequency response of the four cross-coupled microstrip square open-loop resonators with IDTs on SiO2 deposited on Si substrate.

Figure 8 Frequency response of the four cross-coupled microstrip square open-loop resonators without IDTs on SiO2 deposited on Si substrate.

To confirm the existence of the interaction between the EM and SAW waves, devices with the same design have been fabricated on a non-piezoelectric (9000 Å SiO2/Si) substrate. Figure 7 shows the frequency response of the four cross-coupled microstrip square open-loop resonators with IDTs on 9000 Å SiO2 deposited on a (100) Si substrate (sample D). It has a central frequency (ƒo) of 2.43 GHz, a 3 dB bandwidth of 270 MHz (BW = 11.1 percent) and an insertion loss S21 of 7.01 dB. Figure 8 shows the frequency response of the four cross-coupled microstrip square open-loop resonator without IDTs on 9000 Å SiO2 deposited on the (100) Si substrate (sample E). It has a central frequency (ƒo) of 2.46 GHz, a 3 dB bandwidth of 230 MHz (BW = 9.3 percent) and an insertion loss S21 of 8.09 dB. From the above results, the bandwidth of sample D and sample E is 270 MHz (11.1 percent) and 230 MHz (9.3 percent), respectively. Because these two devices were fabricated on the 9000 Å SiO2/Si substrate without the piezoelectric property, the interdigital electrodes just function as coupling capacitors. No matter if the device has interdigital transducers or not, the SAW will not be excited by the devices fabricated on the 9000 Å SiO2/Si substrate. Consequently, the bandwidths of the sample D and sample E are almost the same.

In addition, the relative permittivity εr is related to the electric susceptibility χe, as follows:

and the piezoelectric equation is

However, the SAW propagates on the piezoelectric substrate not only does the elastic wave movement in the medium, but also due to the time-dependent electric field and magnetic field effects that are produced on the piezoelectric substrate.18

where:

P = polarization

Z = stress

d = piezoelectric strain constant

E = electric field

In the presented devices, the piezoelectric wave propagating in piezoelectric substrate influences the polarization, and the dielectric polarization is changed under the influence of the surface acoustic mechanical wave. Consequently, the dielectric constant changes, and the wavelength of the EM wave varies with the dielectric constants. The perturbation of the dielectric constant of the quasi-TEM wave that propagates in the microstrip lines on the piezoelectric substrate strains the frequency response of this device due to the interaction between the EM wave and the piezoelectric surface acoustic mechanical wave.

The coupling coefficient of piezoelectric electromechanical K2 can be defined in terms of the piezoelectric coefficient e, the elastic constant c and the dielectric permittivity e. This equation has already been given as

The dielectric permittivity is changed since the electric field of the quasi-TEM wave that propagates in the microstrip influences the piezoelectric polarization. The electromechanical coupling coefficient K2 is related to the dielectric permittivity and can be improved. The insertion loss of the device is reduced as K2 increases. The increased K2 increases the vibrations of the acoustic mechanical wave on the piezoelectric substrate and the strength of the polarization. Therefore, the characteristics of the device are changed by the interaction between the EM wave and the piezoelectric surface acoustic mechanical wave.

As demonstrated above, it can be seen that the characteristics of the devices on the 9000 Å SiO2/Si substrates are different from those of the devices on the piezoelectric substrates with same design. The electromagnetic wave does not interact with the piezoelectric SAW in the non-piezoelectric material SiO2/Si, 9000 Å thick. The bandwidth will be the same as that of the microwave planar bandpass filter that is composed of the four electromagnetic wave cross-coupled microstrip square open-loop resonators, as shown in Figures 7 and 8. Moreover, the EM wave did not interact with the SAW for the four cross-coupled microstrip square open-loop resonators without the input/output IDTs of the conventional SAW filters, as indicated in Figure 6. Therefore, it can be concluded that the characteristics of the microstrip filters on the piezoelectric substrates are due to the interaction of the EM wave and piezoelectric surface acoustic mechanical wave. Based on these reasons, it is known that the proposed microstrip SAW filters have an extra capacitive coupling effect by the IDTs configuration, resulting in lower insertion loss than that without IDTs. Moreover, it also gives an additional SAW to cause variation on piezoelectric effect, resulting in the bandwidth increasing.

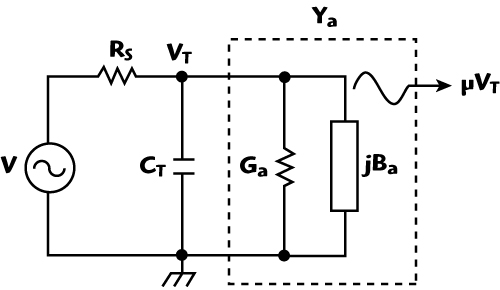

Figure 9 Equivalent circuit of IDT.

Besides, the principle of SAW and equivalent circuit of IDT is used to prove our experimental results. Figure 9 shows the equivalent circuit of an IDT.14

where:

CT = total capacitance of the IDT finger

Ga(ƒ) = radiation conductance

Ba(ƒ) = radiation susceptance

N = number of IDT electrode pairs

CS = static capacitance of one pair IDT

W = IDT finger apodization overlap

K2 = electromechanical coupling coefficient

yo = electrical characteristic admittance of the equivalent SAW transmission line

λ = wavelength of the surface acoustic wave

ƒo = center frequency of the SAW filter

Figure 10 Ga(ƒ) and Ba(ƒ) simulations of conventional SAW filter with IDTs on a LiNbO3 substrate.

Figure 10 shows the simulation results for Ga(ƒ) and Ba(ƒ) on the 64°-rotated Y-cut LiNbO3 substrate. It indicates that when the operating frequency is less than the central frequency, the wavelength is larger than one IDT period and the phase of the current is ahead of the voltage, so Ba(ƒ) represents a capacitance. When the operating frequency exceeds the central frequency, the wavelength is less than one IDT period and an extra delay occurs so the current phase falls behind the voltage and Ba(ƒ) represents an inductance.

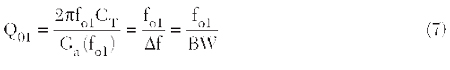

When the operating frequency is the central frequency, if the structure were a typical SAW filter, the radiation susceptance Ba(ƒ) would be zero, as shown in Figure 10. Thus, the quality factor Q01 of the typical SAW filter is

where:

Ga(fo1) = radiation conductance at the central frequency

fo1 = central frequency

Δf = BW (that is the 3 dB bandwidth of the conventional SAW filter)

The conventional SAW filter with the narrower bandwidth is also described by Equation 7, as same as the experimental results, as shown in Figure 4.

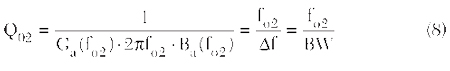

The central frequency of the novel microstrip SAW filter is much larger than that of the SAW filter, so the radiation susceptance Ba(f) of the conventional SAW filter is regarded as an inductance. The quality factor Q02 of the novel microstrip SAW filter is

where:

Ga(fo2) = radiation conductance at the central frequency

Ba(fo2) = radiation susceptance at the central frequency

fo2 = central frequency

Δf=BW (that is the 3 dB bandwidth of the novel microstrip SAW filter)

Figure 10 shows that the Ga(f) and Ba(f) values of the 64°-rotated Y-cut LiNbO3 are high enough due to the higher electromechanical coupling coefficient (K2 = 11.3 percent) as compared with the other piezoelectric materials. The result implies that the novel microstrip SAW filter has a wider bandwidth from Equation 8, as same as the experimental results, as shown in Figure 2.

Conclusion

A novel S-band low-loss wide-bandwidth microstrip SAW filter combined with a 16 micron input/output interdigital transducer (IDT) of 42 pairs with four cross-coupled microstrip square open-loop resonators on the 64°-rotated Y-cut lithium niobate (LiNbO3) was designed and fabricated. The working frequency of this novel filter can be easily increased up to 2.5 GHz without reducing the width of the IDT finger below 1 micron. Due to the interaction between the EM waves and the piezoelectric surface acoustic waves, the performance of this proposed microstrip SAW filter shows a wider bandwidth of 450 MHz and a lower insertion loss of 2.41 dB, and is better than a conventional SAW and microstrip filters, resulting in the bandwidth expansion and the insertion-loss reduction. The four cross-coupled microstrip square open-loop resonators without the IDTs of conventional SAW filters are used to prove these effects. Moreover, the devices on piezoelectric substrates are found to be superior to those on non-piezoelectric substrates with the same metal pattern. Therefore, it is proven that the EM wave indeed interacts with the piezoelectric surface acoustic mechanical wave in this proposed microstrip SAW filter. The principle of the SAW and equivalent circuit of IDT are used to prove the experimental results. Further study is required to elucidate the mechanism of the interaction between the EM wave and SAW in the proposed devices. The device can be easily and inexpensively fabricated using conventional photolithography, a normal lift-off technique and standard piezoelectric materials.

Acknowledgment

The National Science Council of the Republic of China under contract number of NSC 95-2221-E-024-025 sponsored this work.

References

1. H. Matthews, Surface Acoustic Wave Filter, John Wiley & Sons Inc., 1977.

2. R.H. Tancrell and M.G. Holland, “Acoustic Surface Wave Filters,” Proc. IEEE, Vol. 59, No. 3, March 1971, p. 393.

3. J.A.G. Malherbe, Microwave Transmission Line, Artech House Inc., 1979.

4. M.J. Lancaster and J.S. Hong, “Microstrip Filters using New Small Resonant Components,” IEEE Colloquium RF & Microwave Components for Communications, 1997, p. 1.

5. D.M. Pozar, Microwave Engineering, John Wiley & Sons Inc., 1998.

6. R.E. Collin, Foundations for Microwave Engineering, McGraw Hill, 1992, Chapters 7-8.

7. F. Gardiol, Microstrip Circuits, Wiley Interscience, 1994, Chapter 7.

8. U.H. Gysel, “New Theory and Design for Hairpin Line Filters,” IEEE Transactions on Microwave Theory Techniques, Vol. MTT–22, No. 5, May 1974, p. 523.

9. J.S. Hong and M.J. Lancaster, “Canonical Microstrip Filter Using Square Open-loop Resonators,” Electronics Letters, Vol. 31, 1995, p. 2020.

10. J.S. Hong and M.J. Lancaster, “Couplings of Microstrip Square Open-loop Resonators for Cross-coupled Planar Microwave Filters,” IEEE Transactions on Microwave Theory Techniques, Vol. 44, 1996, p. 2099.

11. J.S. Hong and M.J. Lancaster, “Microstrip Slow-wave Open-loop Resonator Filters,” IEEE MIT-S Digest, 1997, p. 713.

12. R.M. Kurzrok, “General Four-resonator Filters at Microwave Frequencies,” IEEE Transactions on Microwave Theory Techniques, 1966, p. 295.

13. B.A. Auld, “Surface Wave Theory,” IEEE Ultrasonics Symposium Proceedings, 1970, p. 1.

14. S. Datta, Surface Acoustic Wave Devices, Prentice Hall, Englewood Cliffs, NJ, 1986.

15. C.K. Cambell, Surface Acoustic Wave Devices for Mobile and Wireless Communication, Academic Press Inc., 1998.

16. A.J. Slobodnik, J.R. Thomas, L. Szabo and K.R. Lake, “Miniature Surface Acoustic Wave Filter,” Proc. IEEE, Vol. 67, No. 1, 1979, p. 129.

17. N.F. Wang, I.T. Tang, C.I. Hung and M.P. Houng, “Investigation of Novel Microwave Surface Acoustic Wave Filter on Different Piezoelectric Substrates,” Jpn. J. Appl. Phys., Part 1, Vol. 43, No. 12, 2004, pp. 8139-8145.

18. Y. Shimizu, “Current Status of Piezoelectric Substrate and Propagation Characteristics for SAW Devices,” Jpn. J. Appl. Phys., Vol. 32, 1993, p. 2183.

19. C. Kittel, Introduction to Solid State Physics, John Wiley & Sons Inc., 1986.