RF power control elements, such as RF switches, are an integral element of any RF system and traditionally have been built using Si PIN diodes for higher power applications and GaAs FETs for lower power and higher speed applications. The use of GaN HEMT-based technology in this application area promises to be a game changer, as GaN HEMT-based switches can simultaneously offer higher power handling and ruggedness capability as well as low control current requirements. They also deliver excellent insertion loss and isolation over an ultrawideband, all within a very small form factor.

These capabilities are demonstrated by the family of RF switch products developed by RFMD. The GaN HEMT-based switches are attractive for multiple applications — MilCom, electronic warfare, radar, test and measurement, commercial infrastructure communications, and medical — as they offer unique advantages over competing technologies. Some examples are silicon-on-sapphire, GaAs FET, pin diodes and even electromechanical switches, depending on the specific application and market drivers. The RFSW2100 GaN HEMT MMIC switch from RFMD is a reflective, hot switchable SPDT switch that offers broadband power handling capability from DC to 6 GHz, with low insertion loss (< 0.4 dB at 2 GHz), excellent isolation (, 39 dB at 2 GHz), fast switching times (, 40 ns), as well as low drive current capability (< 0.5 mA). These devices are available both in die form and in a 3×3 mm, 12-pin QFN package, which is well suited for ease of integration into a variety of applications. The device is designed to present 50 Ω input/output impedance over a broad DC to 6 GHz band and can switch 45 W of uncompressed RF power (defined by 0.1 dB compression of insertion loss). In addition to these capabilities, the RFSW2100 offers a very respectable IIP3 of

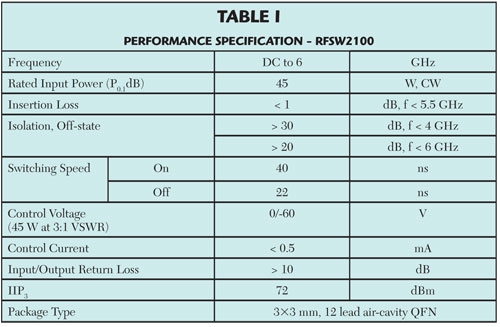

72 dBm, which offers additional possibilities to designers in need of a rugged, high power, low loss switch for more linear applications, as summarized in Table 1.

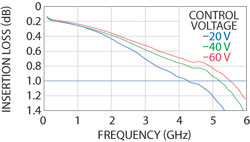

Fig. 1 Frequency dependence of insertion loss.

The RFSW2100 is designed within the same 0.5 µm GaN technology platform as RFMD’s qualified and production released GaN1C process-technology platform and thus benefits from the industry-leading process technology manufacturing control afforded to power amplifier products based on the GaN1C technology platform. Among the key attributes of this process are very high breakdown voltage-per-unit distance and high current density (, 1 A per unit mm of gate periphery) that offer the combination of low RON and the ability to withstand high reverse voltages. This high breakdown voltage capability enabled operation at control voltages of negative 60 V, enabling excellent ruggedness (exceeding 3:1 at 45 W) as shown in Figure 1 and survivability without compromising insertion loss, as the performance improves at larger negative control voltages. The low leakage current (< 1 mA) in the OFF condition leads to low OFF current drive requirements as well as good power dissipation in the OFF state. This power handling and VSWR capability represents a 5× improvement in power handling over a comparable 0.5 µm GaAs FET-based switch. In addition, as the RFSW2100 is a voltage-controlled device, turning the switch ON is achieved by simply biasing to 0 V, with control current in the ON state being almost negligible (< 0.5 mA) up to input powers of 45 W. This offers the RFSW2100 a tremendous advantage over Si PIN diode switches in terms of greatly reduced control circuitry, BOM, board space, weight and cost.

The key small signal figure of merit (FOM) for a switch technology is the product of the resistance in the ON state (RON) and the capacitance in the OFF state (COFF), expressed as a frequency [1/(2 RON·COFF)] or a time constant (RON·COFF). RFMD’s RFSW2100 switch technology offers a figure of merit of 343 GHz, obtained by minimizing COFF and RON. The low COFF results from small fringing capacitances obtained from RFMD’s GaN-on-SiC process as well as the semi-insulating SiC substrate material. The benefits of the thermally conductive semi-insulating SiC substrate are two-fold, minimized leakage current during large voltage swings across the device and maximum heat transfer from the active channel of the device to the heat sink. This excellent heat sinking within the die itself results in very stable high power operation over a wide temperature range as well as linear operation over a greater input power range. Due to the fact that the frequency dependence of the insertion loss is dominated by the COFF, instead of RON, the RFSW2100 provides an industry-leading insertion loss (< 0.4 dB at 2 GHz) over an extremely wideband while offering exceptional P0.1dB power handling (> 45 W) and ruggedness (better than 3:1), rendering it attractive for applications, such as military communication and electronic warfare as well as infrastructure and communication applications.

The RFSW2100 SPDT switch is available both in bare die (RFSW2100D) and in a 3 × 3 mm, 12 lead air cavity QFN package, specifically designed for handling higher power in a compact form factor. This package offers similar advantages with regard to handling the power dissipation in GaN-based devices, similar to metal flange, ceramic air cavity packages that house high power RFMD GaN power amplifier products. Due to the excellent current capability and breakdown voltage afforded by RFMD’s GaN1 process, in die form, this RFSW2100D switch offers an additional power handling capability up to 75 W, depending on the capability of the heat sink environment and mounting, as well as an improvement in insertion loss in the higher frequency range (maintaining < 1 dB of insertion loss up to 6 GHz). In addition to the RFSW2100 SPDT switch, RFMD is developing a family of high power, extremely broadband switches that extend from DC to 18 GHz, enabled by the excellent breakdown voltage and small signal FOM resulting from RFMD’s GaN-on-SiC technology. RFMD’s GaN1-based switch technology also enables development of higher power and multi-throw count switches, which are expected to undergo product qualification in 2012.

RFMD,

Greensboro, NC

(336) 664-1233,