In the telecoms and other RF component markets, today's climate means that there can no longer be a trade-off between cost and performance - the designer needs to achieve both. Temex has recognized this fact and addressed it through the evolution of two new generations of materials on which it will base future resonator designs.

One, E6000, is a material supporting "standard" high frequency performance, achieving this at costs of typically 10 percent lower than comparable existing devices through the use of smaller cavities. The second, E7000, achieves around double the performance of existing top end materials but at around the same cost.

E6000 Material

Initially evolved to address combiner applications in the growing GSM, UMTS and EDGE base station arena, E6000 has been developed to cover frequencies from 900 MHz to 15 GHz. This family of materials is aimed at applications such as low noise block converters for direct broadcast satellite systems, transceiver oscillators for satellite reception, automotive motion/speed radar detectors, dielectric resonant oscillators (DRO) for communication equipment, W-LAN antennas, and microwave filters and sources.

All of these applications need to achieve high performance within a cost constraint. This is accomplished by realizing the required performance within 25 percent less volumetric space than existing equivalents, with consequent savings in component cost and system cost. The main innovation is in the chemical composition, whereby new and innovative oxides have been utilized to achieve the characteristics exhibited by the material. The production process used to produce the parts is more or less the same - pressing, firing and machining.

Performance

The E6000 microwave material increases the dielectric constant to around 45 while maintaining a high Q factor for stable DRO designs. Space requirements are typically 25 percent less in 5 GHz systems, which not only reduces the cost of the resonator (due to savings in the quantity of powder used), but also shrinks the size of the cavity required and hence lowers overall system cost. As an indication, typical Q factor for the material is 8000 at 5 GHz, with a temperature coefficient of -6 to +12 ppm/°C.

The series is available in a wide selection of temperature coefficients all manufactured to tight frequency tolerances. Initially there are seven variants, with temperature coefficients of -6, -3, 0, +3, +6, +9 and +12 ppm/°C, all offering a Q.F of 40,000. Q.F represents the relationship between the Q factor and frequency; for example, if a material has a Q.F of 40,000 then its Q factor will be 4000 at an operating frequency of 10 GHz and 40,000 at an operating frequency of 1 GHz.

E7000 Material

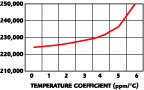

Although E6000 offers the opportunity to achieve high resonator performance at an attractive cost, there are a great many applications where this is not sufficient. However, the new E7000 is a high Q material that consequently achieves very low losses. Figure 1 shows the unloaded Q.F characteristics of the material with regards to temperature. It exhibits a Q.F of 250,000, whereas the company's best material was previously limited to a Q.F of 150,000.

Therefore, it is suitable for higher frequency applications, such as 3G base station filters, ultra-stable oscillators and high performance radio links, as well as some military and aerospace systems. To provide an illustration of its performance when compared to the E4000 family, the E7000 offers double the Q factor at the same cost.

Furthermore, resonators based on this series of materials offer low losses and high selectivity. This new material offers a dielectric constant of 24 ±2 and there is currently a selection of temperature coefficients available, all manufactured to tight frequency tolerances ranging from 0 to +6 ppm/°C.

MEMS Applications

An exciting and growing application for resonators where the E7000 is particularly suitable is tuned micro-machined dielectric resonators (DR) and cavity filters. A recent study1 showed that mechanical tuning can be obtained, based on a movable metal plate placed above the resonator puck, by means of MEMS technology. High resistivity, silicon-based cylindrical dielectric resonators were fabricated in the E4000 material using micro-machining techniques and, depending on the dimensions and on the excited mode, resonance frequencies were in the range of 25 to 50 GHz. However, in this application, E7000 offers the potential for even higher performance, without increasing the cost.

Moving on to methods of increasing performance to improve the frequency stability of a resonator against changing temperatures, spacers (shown in Figure 2 ) can be used to position resonators above the board, rather than directly on it. These discs are made in alumina and are glued to the resonator. Precise performance of a spacer varies from one system to another.

Simulation Software

To help designers specify the correct device from the correct material and achieve a result that meets the required performance within the available cost envelope, Temex is supporting its new materials with simulation software. Using a straightforward data entry screen (as can be seen in Figure 3 ), designers start by entering the required parameters. The program then not only recommends a device, but also simulates its performance in the designer's system. The impact of including a spacer can also be evaluated using this tool.

Conclusion

With other high frequency markets tracking the telecommunications markets downwards, it is essential for designers to offer their customers' purchasing departments a cost-effective solution, and specifiers performance that meets their needs. The E6000 and E7000 materials can address this issue.

Reference

1. W. Pan, P. Fiorini, O. Di Monaco, K. Baert, B. Nauwelaers, R. Mertens, "Micro-machined Tunable Dielectric Resonators," IMEC-MCP, Proceedings of SeSens 2002, November 29, 2002, Veldhoven, the Netherlands.

Temex, Paris, France +33 5 56 46 66 66, www.temex.net, e-mail: frederic.petit@temex.fr. Circle No. 301