In today's fast paced semiconductor industry making accurate and reliable measurements at microwave frequencies is critical to successful product development operations. Microwave measurements enable engineers to characterize both the linear and nonlinear behavior of devices, providing critical performance information. Precise probe contact is a necessity to obtain accurate test data. Precision microwave manipulators must be employed to properly position the probe contacts.

A series of new RF/microwave manipulators has been introduced that feature direct leadnut coupled drives and a number of base choices including a magnetic-assisted vacuum base. The WAVE100 and WAVE200 manipulators, and the PLF/PLS probe head link arms are two critical elements that assure microwave system stability and probe planarity required for sensitive microwave circuit measurements. These rugged rectilinear manipulators have a lead screw pitch of 40 threads-per-inch and feature secure massive mounts to provide stability, even with semi-rigid coaxial cables attached to the probes. The rigid probe head link arms are available in two styles to permit simultaneous use of four probes, and theta and planarity adjustments of the probes are standard.

Five Degrees of Freedom

The WAVE100 (left-handed) and WAVE200 (right-handed) manipulators are engineered with five degrees of freedom. The new manipulators feature five controls that are readily available for fingertip adjustment to obtain the precise probe contact required. The controls are up/down, forward/backward, side-to-side, planarity and 4° of theta control. Probing RF/microwave test structures is now easier than ever. In addition to maximum position control, the large 4.8" x 2.3" base is available in magnetic, magnetic-assisted vacuum, vacuum and mechanical lock mounts. The mechanical lock configuration is easy to use, requiring no tools for setup. Figure 1 shows the manipulator's magnetic-assisted vacuum base configuration. This base style is an excellent choice for occasional use on stations not designed for microwave work, as the magnetic base secures the manipulator from tipping and the addition of vacuum gives it rock-solid stability. Figure 2 shows the vacuum base. The manipulator assembly weighs four pounds and provides a secure foundation for the semi-rigid cables used in most applications. Each WAVE100/200 manipulator requires a link arm to hold and extend the probe head to the device under test. These link arms accommodate probe stations where the chuck is below the platen or where the chuck is above the platen simply by using different mounting holes on the planarity face plate.

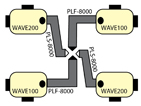

When combined with the rugged PLS (straight) and PLF (right angle) probe head support arms the fixture can easily probe pad sizes of 2 mm with precision planarity and theta alignment, and no probe vibration. Figure 3 shows a possible four-probe test configuration using both WAVE100 and WAVE200 manipulators with PLS and PLF arms.

The WAVE100/200 manipulators are compatible with most manufacturer's probing stations, including Micromanipulator's 9000 series with the RF option for 12" wafers, 4000 Tech Series, 6500 or 8000 series for 4", 6" and 8" wafers. With the proper manipulator base choice they can work with probe stations with or without the RF option. The WAVE100/200 manipulators can support all manufacturer's microwave probe heads, including the industry leading Picoprobe® microwave probe head that can be used at frequencies up to 220 GHz, and features excellent insertion and return loss performance.

WAVE100 and WAVE200 manipulators are currently available with delivery times ranging from six to eight weeks. Additional information may be obtained by visiting the company's Web site at www.micromanipulator.com or by contacting the company's sales staff.

Micromanipulator Co.,

Carson City, NV (775) 882-2400, info@micromanipulator.com.

Circle No. 303