Special Report

Circuit Designers: An Endangered Species?

Ernest Rejman,

Contributing Editor

Back in the Jurassic Period, when the four-function calculator first made its appearance, some greeted it with dismay. "Suitable for imbeciles," spat an elder engineer of my acquaintance. "Now it won't be necessary to even know how to add and subtract, much less multiply and divide!"

When I meekly conciliated that it was just another tool, he brandished a two-foot slide rule at me in a way alarmingly reminiscent of the winning gladiator who has just gotten the go-ahead from Caesar. "Thinking is being eliminated and engineering is going down the tubes! Now we'll raise a crop of even worse ignoramuses! When I use this," he said, again aiming Napier's bones at me, "I must begin with a clear understanding of what I'm after. I've got to know, at least to within an order or magnitude, what my solution is going to be. This thing completely eliminates that!" he ended, using the slipstick to push the calculator from his desk into the trash can beside it.

Now it seems like dŽjˆ vu all over again, when one listens to the jeremiad about what CAD is doing to the analog design engineer, that is, turning him into an endangered species. His frontal lobes are being atrophied by sophisticated CAD software that does not require him to think, only to input parameters at one end to get the design at the other, without knowing what goes on in between.

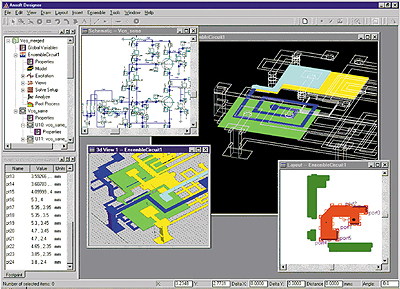

Whichever side of the controversy you fall on, the fact is that analog design has become too complex, and times to market too short, for device layout to be done the traditional manual way, requiring the cell layout to start with a sized circuit schematic and proceed one polygon at a time. All of this followed by optimizations to handle the tight coupling between circuit and layout, resulting in iteration after iteration to tweak the geometries. This process, sometimes lasting days or even weeks, is no longer acceptable (see Figure 1 ).

Fig. 1 CAD systems using physical modeling circuits and electromagnetic simulation plus

manufacturing formats, enabling full-cycle design from concept to tape out. Source: Ansoft.

"CAD's a mixed blessing. You no longer need a design guru. You get a kid out of college, give him an Ansoft or HP tool and off he goes to work on a problem that 20 years ago would have been the subject of a doctoral thesis - that's a great plus. The downside is that he doesn't know the algorithm's shortcomings and limitations. He's a digital weenie putting out analog work. A lot of software is limited, and not very robust. I've seen guys working their buns off at a Sun workstation trying to get something the algorithm couldn't solve because it was beyond the range of the approximations."

Going, Going, Gone?

Graham Etchells, group director of marketing for physical design at Cadence Design Systems, San Jose, CA, tends to agree that designers may be getting close to becoming an endangered species. "There are fewer people coming out of college who want to do analog circuit design. We have some US government stats showing that over the last five years the number of grads doing electrical engineering is declining. So they're in danger of becoming extinct."

Because of this situation, Etchells indicated that companies that do have good circuit designers have increased the pressure for them to perform. "Analog is difficult to do and you need experience to tackle it. Given the convergence between computing, telecom and everything else, there is a lot of pressure on these people; meanwhile, they are becoming a diminishing resource that must be cared for."

"The design engineer is not on the way out. That's like saying that because the word processor replaced the typewriter, writers are obsolete!" disagreed Charles Pott, product marketing and application development marketing section manager at Agilent EEsof, Santa Rosa, CA.

"Circuit designers aren't an endangered species. CAD tools are helping people learn microwave circuit design. There is still a need for critical thinking and a Missouri, "show-me" approach. When taking data on a capacitor, inductor, a transistor - the things we use to build our products - you must be somewhat suspicious about the conditions in which the data have been taken, or how the interfaces are defined. There's a lot of art in that."

Pott then proceeds to segment the different categories of simulation technology existing for the analog area. "In the EDA (electronic design automation) world there are models and libraries for off-the-shelf components. Models for transistors, for passive components. Then there are simulators and a whole simulation technology arena. There is the laying out of your circuit or design, post processing when displaying results. Key areas integrate with other EDA tools in a cooperative design flow - there's also integration with test equipment. It's not all a virtual world because at some point you must actually build a circuit. Our users spend about 20 percent of their time with an EDA tool, which means they spend 80 percent on other things, usually trying to make the design work by building prototypes or doing pilot runs to get it into manufacturing (see Figure 2 )."

Fig. 2 The different building blocks that enable the analog CAD program to

provide the desired result. Source: Agilent EEsof.

CAD can be looked upon as a pyramid, as shown in Figure 3 . It requires accurate models for the simulators, and it must be easy to use and easy to design. At the pyramid's foundation are the models necessary to do accurate design and to avoid garbage in/garbage out. At the middle of the pyramid is simulation technology. To its one side are the different categories of technology, and on the other are specific technologies that are out in the market today. Yellow depicts ease of design or the application layer.

Simulation Evolves

Traditional analog simulators like SPICE have been around for a long time. However, at high frequencies time-domain simulators' applications are constrained. This is because as one goes up in frequency, the number of time points needed to be sampled gets immensely large and the simulation time - sometimes days - becomes untenable. It is in these cases where technologies like harmonic balance, circuit envelopes and others shown in the pyramid become of use.

Fig. 3 CAD requires a number of things to provide what the designer requires: accurate models, simulation technology

and ease of design are among the most important. Source: Agilent EEsof.

"There are time-domain simulators, frequency-domain simulators, numeric simulators," said Pott. "There are also physical simulators similar to electromagnetic simulators where you use Maxwell's equations to simulate the circuit at the most fundamental electromagnetic level. There are many different EDA analog technologies available, although I'll be the first to admit we've simplified design, but not solved all the problems."

Pott points out that even during the present downturn, design engineers are in demand. "The last place companies are cutting spending is in R&D. They must get new products out to market and invent their way out of the current economic climate. The design engineer is pretty safe. There is a shortage of designers and they're under considerable pressure to get their products out to market as fast as possible. Software has not obsoleted designers; it's given them tools that enable them to work faster and build better designs quicker."

"My gripe is that the design engineer's understanding is too one-sided. If you define the design engineer as the person who creates the necessary information to produce an amplifier, he's not an endangered species. However, if the job description is to provide the information to produce the optimum amplifier that satisfies a set of given requirements, then that makes him more of an endangered species. Both a very specific and broad overview of the task must be present within the person doing the design."

The Uneasy Alliance

The digital and analog worlds are blending, mostly driven by communications applications, which in turn are driven by the development and implementation of standards, whether it is Bluetooth or any of the 3Gs. Although the traditional figures of merit for the design of a power amplifier have not changed (gain, compression and third-order intercept), and they are still used and specified, there are now digital modulation schemes. That power amplifier is going to be used with a modulated signal coming through it. Will it perform correctly for that particular modulation standard? This requires figures of merit like bit error rate (BER) and air vector magnitude, which are new specs for the analog designer. It is now required to co-simulate between digital and analog environments - the bits to the analog, to the RF, to the analog, and back out to the bits, and do the overall system simulation. There has been some progress with this, but more breakthroughs are needed to make those simulations faster and to handle capacities.

"Too many people are doing microwave design with a superficial understanding of what's going on. I blame the universities and their big emphasis on optical communications - fiber optics circuits, optical modulators, etc. It's the most visible, sexy research area, and those working it have solid-state backgrounds. However, the work is really high frequency microwaves (optical and actual), because when they output stuff they demodulate and must use microwave equipment. You'd think that they'd encourage the students they hire as research assistants to take the microwave courses and field courses, but coming from a solid-state, often digital background centered on device fabrication, they don't see this, even though digital circuits are speeding up and becoming microwave circuits because of the broad spectrum of frequencies involved."

For the most part, the necessary algorithms are here. What is needed is development on the computer side to make it simulate faster. "Where you solve the problem is inconsequential," said Pott. "The designer wants to do this virtual test in the EDA software, and do it quickly. Many EDA vendors have kept to their analog world or their digital world. The future belongs to a hybrid, which makes it interesting to see how it'll play out."

"The young engineer using CAD must take the time to learn and understand the basic algorithm behind the solution he's after. It's the same as punching numbers into a calculator as opposed to using a slide rule. With the slide rule you needed some intuition as to where things were going because it determined how you'd slide the stick. You don't get that with a calculator or a CAD program."

Another reason why a majority of people in the industry do not believe the designer is going away is that circuit complexity is on the rise. It is because of these enabling tools, and because standards are getting more complex, that designs and the complexities and the capacities of the circuits are getting larger. There is more challenging work on the horizon for the designer. "Our users want larger capacities," said Pott, "thousands and thousands of transistors; meanwhile, they're trying to integrate more on the chip to reduce costs." Work is proceeding to enable CAD software to handle these higher levels of integration.

Whither Accuracy?

When performing fundamental, electromagnetic simulation, EDA is fairly precise because it simulates Maxwell's equations and there is not approximation. However, in the analog world there exist different levels of abstraction. At the circuit level the designer is modeling and this requires accurate models, because those models are characterizations and approximations of how a transistor behaves in an analog situation, how it functions in a high frequency situation. Accurate simulations without accurate models are impossible. In the digital world, however, everything is 1s and 0s and it is easier.

The transistor is the most important part of the modeling arena. If the designer does not have a good transistor model, the simulations will not be accurate. "Over the years, academia has produced numerous technical papers and capable people who have developed equivalent circuit models for the popular transistor, whether it is a bipolar or a FET," said Pott. "There are many such characterizations and models. A whole engineering science has developed around producing accurate models for transistors, of which 80 to 90 percent are in our simulators."

"CAD's principal problem isn't technical, but business-related. Characterizing the devices that the designer uses is still a challenge. Many designs use components from different manufacturers, such as surface-mount devices. The quality of the models that vendors provide limits how far you can go with these tools. It isn't that Microwave Office or Ansoft tools aren't any good, but if you're feeding garbage in you aren't going to get very good results."

Another way you ensure accuracy lies in a blending of the test equipment world with the software world. "We have equipment and software that is solely sold to our users to extract accurate device parameters for modeling a transistor," said Pott. "Sometimes they have groups dedicated to getting those accurate models and using test equipment to measure transistors and characterize them." Still another method involves database models, which should not be confused with approximations. The transistor is characterized by measuring it different ways. These measurements are then used in the simulation.

There are models and then there is simulation technology. Simulation technology is the algorithm that inverts a very large or a sparse matrix. Models are the building blocks. The development of simulation algorithms is largely independent of the characterization of a model.

Design software must be easy to use. The software developer must consider making menu picks, usability testing, icon choice and how it is used or where it is placed on the screen, how many mouse clicks are required for an operation and many other factors. Ease of design is a superset, and it is critical, especially in high frequency and analog EDA. However, the utility of the software must also be considered - it must match current needs. "If years ago somebody had tried to sell me a SPICE simulator - a time-domain simulator - but I was tasked with designing an amplifier, why would I need a time-domain simulator? There is a simulation algorithm technology, and then there is what I am trying to design," said Pott.

Pott added that there is a large gap there between the technologies that get pushed out into the market, whether it is harmonic balance or circuit envelope technology, time-domain or convolutions. "Users look at it and say, 'Great, but I'm trying to design a mixer, an amplifier, an LNA, a Bluetooth transceiver.'" This is a good reason why this gap exists. It is unique to the EDA world and high frequency and analog. "If you were the CEO of a CAD company and wondered what kind of people you need to hire for your R&D lab, you'd decide that you need to hire people who know C++ and have programming skills, people who have simulation algorithm knowledge - possibly who wrote their theses and got their PhDs on different types of algorithms - and they also need to know how to design circuits for high frequency applications. They do not exist."

What happens then is that the EDA companies' marketing departments market the technology in the algorithm and miss the mark because the users are left wondering how it applies to their technology. Because of this skill set challenge, most leading CAD companies work with partners, sometimes ex-customers who are power users, as consultants to build an application layer on top of the core technology.

Over the coming years the blending of the worlds of test and simulation will continue. This is important because the average design cycle is about 53 weeks, with perhaps the first month spent in EDA work, and then the rest working to get it into manufacturing. EDA is still somewhat isolated from the world of test. If these two are even slightly blended, it becomes possible to do many desirable things. If in a design team someone is designing an amplifier and another a mixer, and one finishes ahead of the other and begins measuring his design, it would be advantageous to take the simulation that the other person is still working on and plug into that result so that in the real world the mixer design is stimulated with the amplifier's exact signal. This would save considerable design time by removing some of the risk. So whether the software is used as a source for the measurement, or the measurement as a source for the software, this could shrink the design cycle.

"It's better now. I remember working a Model 29 keypunch machine with stacks of cards and an IBM 360. Back then, you had to hop in the car and take your card deck to the computing center. Sometimes they'd finish it, sometimes not. Once some son of a beagle dropped my 1200-card deck and I got them back scrambled. I sat with the stack, putting them in the 100s category, then the next, and so on. What a mess! Later I learned that as I key-punched them, I could have had them automatically indexed to avoid the problem."

Making Up for Experience

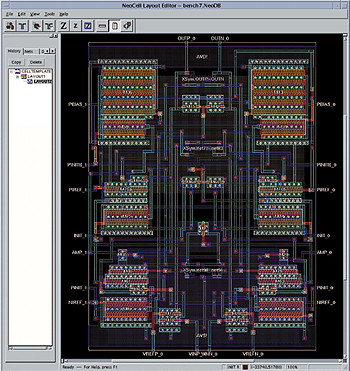

Like its competitors, Cadence Design Systems is trying to provide that shrinking pool of circuit designers with tools and technologies to enable them to become more productive. One of its products, NeoCell, is specifically aimed at this. "It allows experienced designers to capture all their knowledge of circuit design - their analog IP - into the circuit itself in the form of constraints and information that is archived and can then be passed on to the people doing the layout, or to more junior designers who do not have the same level of experience," said Etchells.

"Designers today need on-the-job training. There's too much dependence on the CAD program's magic algorithms, and less on solid knowledge. CAD's made it possible to design and get results without fully understanding why, but it's not the best way to proceed - people no longer understand network synthesis, and other things that used to be basics."

These same circuit designers can produce analog layouts in a matter of hours vs. days or weeks. So while there is an increasing need for analog design capability, the pool of expertise is shrinking. "The only way to keep pace with demand is to give designers better technology and tools to make them more productive," said Etchells, adding that this is also true of those who do the mask layout. "Typically, the way many of our users work is that they have circuit designers, then they have layout people. The circuit designer ratio is usually about 3:1 - three circuit designers keep one mask designer busy. The problem is that there are fewer circuit designers and fewer mask designers, and the level of work is increasing."

Mask design is considered by many a low level technical skill set. In Silicon Valley, many of those who do mask design are old-timers whose background is rooted in graphics design or art. This is because laying out polygonal information was considered to be more of an art than a science. Many of these experts are getting on, and skilled replacements are getting increasingly more difficult to find. "You can get junior people, but that's of no help when you have two weeks to get a chip out the door. You cannot bring someone quickly up to speed on how to do analog layout," said Etchells (an example of design software used to capture the designer's knowledge in the form of achived information can be see in Figure 4 ).

Fig. 4 Some design software is being architectured to give it the capability to capture

the designer's circuit design knowledge in the form of archived information that

can be used later for other designs. This is a way to preserve the ever-shrinking pool

of human design expertise. Source: Cadence Design Systems.

There is a desperate need for the further automation of analog design. Industry observers agree that the analog design world must quickly get to the point at which the digital design world is at today. "High level languages, analog HTLs, the whole system being driven by electrical specs, so that you can go through a synthesis-type of exercise and at least get a first cut of your circuit," said Etchells. "We're working on something like that, and there are companies like Neolinear that not only provided us with the analog layout portion of our portfolio, but they're also working on automatic circuit sizing. It is not too far to take that to the next level, where you drive the whole thing from an analog HDL, some description of the top level." Once it was thought digital design could not be automated to the level at which it is today. Analog must get to the same point. Will it work to the same degree it does with digital? "Maybe and maybe not," said Etchells. "But at least you can take out 80 to 90 percent of the effort to get to a first cut of the design."

"Trust but verify! Know the software limitations, because you must ensure that your approach is valid - don't be satisfied with only one tool. Play one off another and, if it comes to it, dig into the algorithm itself to see what's going on. Don't get yourself into a position where you have a limited view of what's going on. You must become a generalist, not a one-trick pony."

Digital design is either yes or no, whereas analog still holds uncertainty. As software development progresses, much of this art will turn to science. Analog designers are in demand because analog is still pretty much a dark art. The engineer would end up with a layout that is laid out in a certain way: this device and that device are matched in their orientation. Why? Nobody really knew, but the designer has years and years of experience and knows that if he does it exactly like that it will work. He does not have the luxury of figuring out what the tolerance is between those devices, but knows that if he does them exactly the same way they will behave correctly - all based on painfully acquired empirical knowledge.

"I've designed many devices using the empirical method. Having the option to check things out and try different variants with a powerful CAD tool is fun and productive. True, with the old approach I used my intuition, but I had to make a variety of design cuts, measure them, and then infer from this in which direction to go. The hit-or-miss approach has been greatly reduced and so has the penalty for having the wrong instincts, as long as you're willing to go through a design methodology where you really test and analyze your ideas with your favorite CAD program."

Now these empirical methods, these heuristics, are being captured and stored in the design for future reuse. In the case of Cadence's NeoCell, a very experienced analog designer can put that kind of information into the schematic as he builds up his circuit. For example, these two devices must be matched, they must be interdigitated and have a guard ring around them. That information then gets carried forward through to the placement and routing of the circuit, and it will do so forever.

Later, if the same topology is taken (an op amp is an op amp is an op amp) and what was built at 0.50 mm now must be done in 0.35 mm, the same sets of constraints still apply. For example, it is still going to be interdigitated at 0.35 mm as it was at 0.50 mm. "You no longer must go through the exercise of finding someone who knows how to do it," said Etchells. "You capture it once, reuse it, re-target it, it is consistent and it enables you to do 'what-if' scenarios at the layout level." Nevertheless, Cadence is convinced that it will never be possible to take the engineer out of the loop. "What you can do is make his life much easier, and him more productive and allow him to pass on the knowledge he has gained to the next generation."

"CAD shouldn't be viewed as a black box where you input parameters at one end and the design pops out at the other. Now you have the ability to look into the detailed operation of each individual part of a multistage amplifier design, for example, and truly optimize it. This was impossible 30 years ago - too much tweaking had to take place."

We live in the brave new era of CAD. Whether or not this has degraded the design engineer's ability is moot. Compared to his present-day counterpart, yesteryear's design engineer undeniably had arcane skills that are fading or have passed away. The profession, academia and industry should view this loss with neither alarm nor resignation. After all, we are no longer taught how to make fire by rubbing two sticks, or the finer details of dugout canoe construction.

Once these skills were crucial, now they are quaint.

ACKNOWLEDGEMENT

The author would like to thank the "Old Elephants of Microwaves" for the recollections and comments - made under solemn promise of anonymity - which are interspersed throughout this article.

Eulogy for a Slide Rule

Alexander E. Braun

Recently, I went shopping for school supplies with my nephews. After gathering armfuls of loose-leaf paper, crayons and homework folders depicting in full color the current Saturday morning superheroes flexing abundant muscles, we passed by a dusty shelf in a dark corner.

"Hey, Unc, look!" said the oldest one. "Can we have the fancy rulers? They're better-looking than the plastic ones."

I squinted into the shelf and saw a neat pile of Pickett slide rules barricaded behind gray dust balls, surrounded by the Great Spider Burial Ground.

The yellowed sign inside read, "Slide Rulers, 50% Off."

"Those are not rulers," I informed the world through clenched teeth.

The salesgirl approached us. "May I help you?" she asked.

"Yeah," replied my nephew. "What are those things?

She slid open the door in the back of the case, viewed the desiccated remains inside with distaste, muttering something that sounded like "Gross!" and took one of the Picketts out. "Beats me," she shrugged after examining it. "All I know is the manager said they don't make them no more."

Tenderly, I took it from her hand. My thoughts tumbled back to my first encounter with one of these instruments.

I was an eighth grader; Eisenhower was in the White House and the International Geophysical Year was the big science news. Then science commanded awe and respect, and we were all dying to have a career in it. I wanted this most of all because of my special status with the guys: I'd written to, and gotten a reply from, Dr. Werner von Braun. (Yes, I still have the letter and blood will run in the streets before I surrender it!) But for science you had to be good in math; under stress, as during exams, for example, I'd often forget my multiplication tables and had to resort to long addition or subtraction. Then I got momentous news: my future high school's math department allowed students to use slide rules in class and even during exams!

This seemed incredible, especially to someone like me so well acquainted with all kinds of scientific instruments. ("A slide rule? Well, it's like a ruler, made up of three - no, four - pieces. Two don't move and the third slides in between. And there's a marker to find the answers and on the three pieces are a bunch of numbers - logarithms - you use to get the results.") A slide rule? Of course I knew what it was! I'd seen them in movies and read all about them in Fantasy and Science Fiction magazine. With a few minor adjustments the hero could figure out how to veer his spaceship away from the Dark Star and save the Venusian princess! A regular pocket brain! Why, none of Robert Heinlein's snotty young heroes ever came to anything until they learned how to handle one!

That year, after a barrage of unsubtle hints, my folks gave me my first slide rule for my birthday: a resplendently beautiful six-inch Pickett. It came with a real leather clip-on carrying case inside a pasteboard box, and had an "easy-to-follow" instruction booklet. I opened it with trembling fingers and learned it was made of a mysterious alloy that resisted expansion and contraction due to temperature changes, preserving my small magic wand's accuracy, and that it was surfaced in an "exclusive yellow-green color of 5600 Å to minimize eye fatigue." Imagine that!

My only disappointment came when I discovered slide rules neither add nor subtract. I soon got over that heartbreaking development, however, reasoning that I really wanted it to shore up my sagging multiplication and division abilities, and it did that admirably. It was the only other thing I ever taught myself to do. (Except for how to play the harmonica, which I still do - backwards, because nobody told me the low notes are supposed to be on the left side and the high ones on the right.)

When high school started, I called it my "slipstick" with easy familiarity, and could make it sit up and beg. My mathematical abilities firmly entrenched themselves in the college-aspirant range of B, B+ and, on occasion, A.

The year I was to take physics I learned my small rule would be inadequate. A bigger, more "powerful" instrument was needed. My father sighed and got me a dazzling 12-inch Dietzgen. Satan was a dope - had he tempted Martin Luther with it, he wouldn't have had an inkwell tossed at his head.

Back then, the big slide rule was the status symbol; only college prep students had one. We'd carry them in their cases, hooked from our belts, and swagger down the halls feeling like so many space-age d'Artagnans, our trusty slipsticks slapping against our legs; or nonchalantly wave them while engaging in meaningless calculations in front of uncaring jocks as they grunted to even more uncaring cheerleaders.

At college it became undignified to dangle a slide rule from your waist as if you were headed for the O.K. Corral. So I bought myself my third and last slide rule: a five-inch-diameter circular Pickett, equivalent to a 50-inch linear one. To this day I carry it everywhere. It still looks impressive to the uninitiated, lying carelessly on the desk, extended scales facing up.

Undeniably, electronic calculators are far more practical, precise, can graph and even add and subtract. I confess I'd feel lost without mine. But somehow it's not the same thing and in the younger borders of my mind, where Ike is still President and Tranquility Base is perhaps a 2001 possibility, there stands the lone hero, surveying the desolate Martian landscape through a shattered faceplate, his patrol ship disabled, worriedly fingering his trusty slide rule to figure out a way in which to bend natural law and turn back the dark tides of the Galactic Warlord...