Used for food preparation since the 1950s, heating, warming and cooking in a microwave oven still operates on the same principle as it did 60 years ago. Microwave ovens are powered by magnetrons, tubes used to generate high-power microwave energy. Magnetrons lack controllability, as they can only be switched on or off, making microwave ovens practical only for defrosting frozen foods and reheating pre-packaged meals. As foods have different energy absorption properties and inhomogeneous energy density, the inability to control the power from a magnetron explains why the typical microwave oven produces food that has inconsistent temperature-the dreaded hot and cold spots.

With control of the power, frequency and phase, the right amount of energy can be applied to each food item on a plate, overcoming these limitations. Using solid-state RF energy in future microwave ovens will offer an entirely new user experience, where the cooking is accurate and high quality, enabling someone to click a button and tailor the cooking to specific foods-even multiple foods on the same plate-without having any item over- or under-cooked.

An additional benefit using solid-state RF energy will be significantly longer oven lifetimes, without the magnetron’s power degrading. This reliable cooking performance will assure food safety, which is crucial in all kitchens.

IMPROVING RF ENERGY DISTRIBUTION

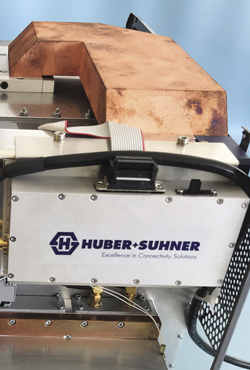

Figure 1 Solid-state RF energy systems require high-power connections to PCBs.

Introducing a completely new technology requires many changes, beginning with design. Magnetrons are directly mounted to rectangular waveguides; however, with solid-state RF energy, power amplifiers on printed circuit boards (PCB) need to be connected to the appliance (see Figure 1). Along with the common electrical challenges, such as ensuring low loss and handling high-power, the design approach must cope with more filigree mechanics compared to a metallic magnetron cavity. The tolerances in the oven assembly are tighter with a PCB assembly compared to those required with the magnetron.

To develop an affordable and reliable assembly process without using cables, new interconnect concepts are needed to solve the mechanical challenges. The RF cables and connectors used to connect PCBs in other applications and industries do not meet RF energy’s requirements for power handling, and they are more expensive and complicated to assemble.

Figure 2 The RFEX connector is directly integrated into the power amplifier housing.

Addressing these issues, HUBER+SUHNER has developed an RF energy connector, the RFEX, for optimal RF power handling and performance. The first of its kind, the RFEX is a record low-cost solution for high volume RF energy applications. It is directly integrated into the amplifier housing, as shown in Figure 2, which significantly reduces the size and number of parts, simplifies shielding and minimizes electromagnetic compatibility problems. To save space, the RFEX can connect directly to an antenna, enabling direct mounting of the amplifier. Alternatively, the RFEX connector is a low loss interface to hollow or polymer supported waveguides.

POLYMER SUPPORTED WAVEGUIDES

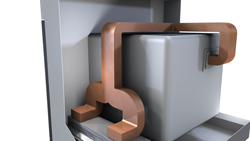

Polymer supported waveguides (see Figure 3) can be hollow structures, dielectrically loaded or partially loaded with a dielectric, allowing the size and weight to be adjusted to meet the application’s power and loss requirements. Polymer supported waveguides provide a high degree of flexibility: all the mechanical structures can be designed to fit the form factor restrictions of modern oven cabinets.

Figure 3 Polymer supported waveguide connecting a power amplifier assembly to a microwave oven cavity.

To achieve the full benefit of solid-state RF energy, multiple power amplifiers are typically used, requiring multiple feed points and combining the powers from the separate amplifiers, as shown in Figure 3. The extremely high degree of design flexibility allows the connection of multiple amplifiers to multiple feeding points of the cavity, even in geometrical difficult applications. Polymer supported waveguide power combiners have distinct advantages compared to PCB-based combiners: lower losses and lower cost, with a significant reduction in PCB area.

Designed to handle the typical high-power levels with the lowest possible losses, the highest efficiency and low heating, the RFEX connector and polymer supported waveguides enable a highly reliable, long life solution. Because of the innovative design, the combination simplifies previously tedious assembly processes. By reducing the number of parts and using production concepts new to the RF energy industry, users benefit from significantly lower cost.

RF ENERGY TO CHANGE OUR LIVES

Solid-state RF energy for cooking will bring completely new features into high-end cooking devices, including faster, more repeatable and high quality cooking, which restaurants, especially, will benefit from. Solid-state RF energy will enable a range of applications, not only cooking, warming and heating food. Automobiles can have improved ignition, reducing fuel consumption. RF energy can power plasma lighting, creating a spectrum much closer to natural sunlight than provided by LEDs. In medical applications, such as the RF assemblies used for microwave ablation, RFEX can improve reliability and simplify the RF signal path. Industrial applications often require huge power levels, requiring many power amplifiers. The RFEX and polymer supported waveguides can combine from two to more than 16 amplifiers in sub-units, achieving the goal of increased flexibility, simplified maintenance and reduced total cost.

For some applications, HUBER+SUHNER RFEX interconnectivity solutions can combine polymer supported waveguides with larger diameter coaxial cables to support different geometrical distances, power levels, ambient temperatures and durations. The HUBER+SUHNER RF energy solutions comes from its extensive experience in the design and development of RF connectivity products.

Just as mobile communications completely changed our lives, RF energy will change many industries, making processes faster, more reliable and more affordable.

HUBER+SUHNER

Herisau, Switzerland

www.hubersuhner.com