The Next Level of Design Automation

Applied Wave Research Inc. (AWR)

El Segundo, CA

Microwave Office 2000 Version 4.0 begins shipping in December of this year. The latest release of the popular electronic design automation (EDA) suite includes revolutionary new capabilities for automating the high frequency design process by integrating design synthesis with simulation and manufacturing methodologies. Version 4.0 includes a built-in automation language that provides users access to Microwave Office's underlying object model, enabling synthesis, links to manufacturing and other design-automation features. It also includes a completely new harmonic balance simulation engine, which is orders of magnitude faster than previous versions. The layout editor has been enhanced to include interactive design rule checking (DRC) and professional "polygon pushing" capabilities for complex MMIC and RFIC layout. A patented learning optimizer can slash weeks off design schedules by rapidly solving problems that cannot be tackled using conventional optimization techniques.

DESIGN AUTOMATION INTERFACE

This is the first Microwave Office release to include an open design automation interface that provides users access to its underlying database and functions. This capability enables seamless integration of design synthesis with engineering analysis, as well as unlimited links to manufacturing tools and other design-automation objectives. Microwave Office 2000 enables these capabilities by providing users with access to its underlying object-oriented database through an Application Programming Interface (API). The mechanism used to access the database is Microsoft's Component Object Model (COM), also known as COM Automation. Microwave Office allows the application to be controlled from any programming language or scripting engine, such as Visual Basic, Java Script, or a compiled language, such as Visual C++.

DESIGN AUTOMATION CAPABILITIES

The Microwave Office 2000 design automation interface can provide new levels of productivity for integrating the entire design methodology. The COM-based API available in Microwave Office 2000 can be used both to automate tasks and to extend the capabilities of the design tool. The following list is just a sample of what is possible with the new design-automation interface.

* Design "wizards" can be easily created to automate routine design tasks. This provides a generic mechanism for adding specialized synthesis capabilities such as filter- or matching-network synthesis.

* Microwave Office can be used as a component in an automated testing or manufacturing environment. Integrating together several applications or test instruments that support COM scripting can create a complete manufacturing or testing system.

* The COM interface can be used to create a bill of materials, parts list, or any other type of document that can be generated from the design database.

* The COM API allows Microwave Office to be used as a design framework that ties together different programs. Any programs that run within the environment can leverage the existing tools that are built into the framework.

* Third-party tools can use the Microwave Office design database to perform other types of analyses. For example, a program that performs thermal analysis on the physical layout could be integrated with Microwave Office.

* Scripts can be written to automate complex design tasks within Microwave Office. For example, a script could generate all the slides necessary for a design review by automatically generating a complete presentation in PowerPoint.

* Users can add specific functionality or features to Microwave Office to specialize it to their own design problems. For example, optimization of EM structures can be scripted and executed with a simple routine.

Microwave Office includes a built-in scripting language that uses standard Visual Basic syntax. The built-in Visual Basic scripting allows the creation of macros and utilities that are created and executed entirely from within the Microwave Office design environment. The built-in scripting engine also includes a powerful debugger and supports syntax highlighting. Although scripting engines have been available within other EDA applications, the traditional approach has been useful only for automating tasks within the application; it has not allowed the program to be integrated with other applications by means of a common scripting language. The design-automation scripting approach using traditional methods, shown in Figure 1 , uses a scripting engine that runs within the application itself.

This approach has several disadvantages when compared to Microwave Office 2000's COM-based approach. One of the most significant is that the API uses a closed and typically proprietary language that is unique to the application. These languages require users to learn specialized syntax that is not transferable or portable to other applications. Another disadvantage is that the scripting languages can be used only to control a single instance of the application itself and cannot control any outside applications.

Applications like Microwave Office, that use COM automation, share a common programming interface that can integrate any of the thousands of COM-compliant applications, including all Microsoft Office applications, SolidWorks, Matlab, Labview and many others. A single COM automation client (such as a Visual Basic script) can create or connect to instances of applications that are COM automation servers. Any data extracted from one application object can be used within any other application object. A single automation client is visible to applications on a user's computer and can also access data through a network, intranet or via the Internet. Figure 2 shows how a single COM scripting engine could control a number of other applications, including Microwave Office.

From a programming standpoint, it does not matter if the scripting engine built into Microwave Office or another external automation software is used to control the applications (including Microwave Office). However, the built-in scripting engine allows the execution of the programmed scripts through the Microwave Office environment. With the COM automation approach, the user has a choice of standard languages that are well supported and well documented. For example, hundreds of books discuss Visual Basic and C++, while books on proprietary scripting languages are often nonexistent.

COM automation was designed for use with object-oriented applications. A COM automation server exposes the underlying object model of the application as objects within the scripting or programming environment. This allows powerful object-oriented software techniques to be used for the scripts or programs that control applications like Microwave Office. Object-oriented APIs have many advantages compared to flat functional APIs. Flat APIs require that all operations performed on the underlying software application be performed through a set of functions that manipulate the underlying objects in the application. The limited set of functions in the flat API restricts the operations that can be performed on the underlying object while an object-oriented API allows direct manipulation of the underlying objects. A flat API with the same level of functionality would need to have interface functions for an extremely large set of operations that arise from the different permutations of operations that are possible through the objects.

NEW HARMONIC BALANCE SIMULATOR

As digital communications standards like W-CDMA, EDGE, and Bluetooth become more pervasive, the need to pass complex modulated signals through nonlinear circuits becomes more critical. Version 4.0 was designed to handle this increased complexity by integrating a radically improved harmonic-balance simulator based entirely on Krylov subspace methods. The new simulator is so efficient it can handle complex modulated signals with arbitrary-length data streams and pass the entire spectrum through nonlinear circuits such as mixers, power amplifiers and multipliers.

Krylov methods are a class of methods for solving linear equations (matrix equations) using iterative techniques instead of such methods as Gaussian elimination, which are best known among engineers. Krylov methods are very fast, especially for large problems, so they are especially well suited for harmonic-balance analysis of large circuits. These methods are significantly faster than more conventional harmonic-balance circuits even for small circuits. In implementing Krylov methods, it is tempting simply to replace the matrix solving routines in the simulator and keep everything else the same. However in Microwave Office, the harmonic-balance simulator has been optimized around the Krylov methods; this approach results in an extremely fast and accurate harmonic-balance simulator.

An important advantage of Microwave Office's object-oriented architecture is the ability to modify the software to integrate the improved technology quickly and easily. This enables the developers to invest their time into optimizing the simulator, rather than dealing with the complexity of code interactions. With simulators designed around the older, "structured code" methodology, it can be extremely difficult and time-consuming to make major modifications, because of the large number of interacting subroutines that make up the simulator. However, in an object-oriented simulator like Microwave Office, simulators are realized as C++ objects, and all the code operating on the simulators' data is compartmentalized in an object. Therefore, it becomes relatively simple to improve the simulator by replacing modules with more advanced algorithms.

Microwave Office 4.0 now includes a very general capability for nonlinear noise analysis. It is especially useful for noise analysis of mixers and noise exacerbation in multipliers and power amplifiers. Nonlinear noise analysis is much more complex than linear noise analysis, primarily because it must account for correlated noise sidebands around each large-signal harmonic, and because the device models must predict noise levels accurately throughout their entire range of large-signal voltages and currents. The noise analysis in Microwave Office has been carefully designed to do this.

LAYOUT EDITING FEATURES AND DESIGN RULE CHECKING

The design of complex RFICs and MMICs has, for many years, been an extremely time-consuming process. A great deal of the difficulty stems from the requirement that high frequency IC designers must painstakingly verify their layouts against simulation parameters and check their design against the foundries' process rules. Often times, engineers are saddled with methodologies that require numerous manual iterations between a separate simulator used for analysis and complex IC layout tools used for design verification and mask generation. This design methodology has always remained more complex than necessary because of missing functionality or incompatibilities between the simulation and layout tools. It is also disturbingly error-prone.

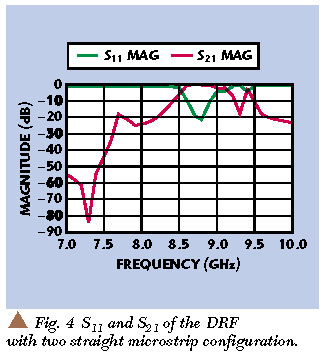

Microwave Office 4.0 addresses the IC designers' requirements by integrating powerful mask editing and DRC capabilities directly with the simulation environment. With Version 4.0 a fully featured IC layout editor and interactive design rule checker are integrated with the harmonic-balance simulation and EM-analysis tools. In fact, the simulators, schematic entry and layout tools all share a common object-oriented database. The design-verification capabilities run interactively from a common design environment, so that microwave engineers get instantaneous feedback if they violate the foundry design rules. The productivity benefits can slash weeks off the development schedule by reducing iterations between the design team and the foundry. Libraries are available for many MMIC and RFIC foundries. Figures 3 , 4 and 5 show various Microwave Office 2000 capabilities.

NEW NONLINEAR AND LINEAR MODELS

Microwave Office 2000 includes a number of new nonlinear device models, including the first implementation of a new pseudomorphic high electron mobility transistor (PHEMT) model. Based on the recent work of Angelov of Chalmers University in Sweden, this new PHEMT model includes improved modeling of capacitances, breakdown phenomena, and drain-dispersion effects. Another important addition is the industry-standard BSIM3 MOSFET model, developed by the University of California at Berkeley. The latest version of BSIM3 (Version 3.2.2) has been implemented in Microwave Office 2000, and despite the extreme complexity of the model (with over 160 parameters and several thousand lines of source code), the efficiency of the implementation within Microwave Office is excellent. Performance differences in speed between BSIM3 and other MOSFET models are barely noticeable. Microwave Office now includes, among others, the Parker-Skellern FET model, one of the most accurate general-purpose models available, and the Fujii model, an excellent model that is relatively easy to use, now becoming quite popular in Japan. The Triquint TOM3 model is also included in this release.

On the linear simulation front, Microwave Office has over 50 new models for transmission lines, baluns and other structures, including a comprehensive library of coplanar waveguide models. The coplanar library has been synchronized with parameterized layout cells to provide a seamless design flow for coplanar applications, such as flip-chip MMICs. Also included are multicoupled microstrip and stripline elements that rely on quasistatic EM simulations. *

Applied Wave Research Inc.,

El Segundo, CA (310) 726-3000.