Warfighters rely on sensors in war zones that provide critical information. Sensors watch over roads U.S. armed forces travel. They detect when adversaries bury improvised explosive devices.

But to constantly monitor battlefield conditions, sensors are always “on” to detect vibration, light, sound or other signals for situational awareness and to inform tactical planning and action. With their current dependence on small batteries with short lives, sensors can put soldiers in jeopardy by forcing them to expose themselves to ambush attacks while changing sensor batteries.

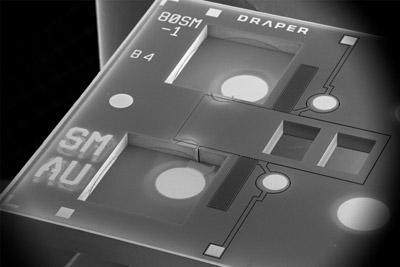

Draper addressed this challenge by developing a sensor that awakens only in the presence of target acoustic signals—and requires far less power to operate. In a radical redesign, Draper engineers found they could reduce the sensor’s standby power needs to near-zero if they built the sensor as a microelectromechanical system (MEMS).

“Sensors constantly consume power, with much of that power spent processing what often turns out to be irrelevant data or noise,” said Jonathan Bernstein, a microelectromechanical engineer at Draper. “We solved that by designing a zero-power acoustic wake-up switch actuated by environmental sounds that will enable sensor systems to last for years, limited only by battery discharge rates.”

Bernstein invents, designs and fabricates novel MEMS devices. A paper on the Draper’s new sensor has been submitted to the Journal of Microelectromechanical Systems. Their discovery could be useful for extending battery life by conserving energy and reducing drain, a beneficial feature for both internet of things devices and unattended ground sensors, the paper said.

“One area where sensor systems need to advance is power consumption and battery life,” said Marc Weinberg, design engineer in Draper’s Mechanical Engineering and System Packaging division. “As sensors move into more applications, from the military, to our homes, to the internet of things, there’s a search on for ways to optimize battery consumption. We believe an acoustic wake-up switch shows promise for the future of sensors.”

The current research into MEMS, which was funded by the Defense Advanced Research Projects Agency (DARPA) for its N-Zero Program, is part of Draper’s materials engineering and microfabrication portfolio. Draper develops sensors for energy, transportation, defense and cybersecurity and excels at developing extremely small sensor systems with surprising sensitivity and resolution that are cost-effective and thus easier to distribute widely. Draper facilities in Cambridge include a microfabrication center, MEMS facility, polymer fabrication, precision machine shop and a Center for Additive Manufacturing.

The journal article, titled “Resonant Acoustic MEMS Wake-Up Switch,” was written by Bernstein and Draper engineers Mirela G. Bancu, Eugene H. Cook, Amy E. Duwel, Richard D. Elliott, Douglas A. Gauthier, Stephanie L. Golmon, John J. LeBlanc, Michael Tomaino-Iannucci, Jonathan S. Ung and Weinberg.