Development speed is a major concern in today's products' life cycle. Ranking alongside the raw costs involved with prototyping a device, time-to-market is the one key constraint imposed on design engineers. Consequently, any innovative or competitive advantage can easily be lost if advanced ideas get stuck in a long pipeline of reiterations before finally becoming a marketable product. In an increasing number of disciplines, full 3D electromagnetic field simulation is becoming the sine qua non, to advance the prototyping, virtually, to a stage where the realization does not unexpectedly deviate from expectations. In many respects, a simulation is much more informative than a prototype, as it grants unlimited insight into the mechanism that makes a device succeed or fail.

In response, CST is taking up the challenge of implementing leading-edge technology, providing versatility and increasing usability with the development of Version 5 of CST MICROWAVE STUDIO® (CST MWS). Based on a long software history, the very general theoretical approach reveals its full power in the wide range of applicability, covering static and low frequency applications (via CST EM STUDIO™) to the highest frequencies in the optical regime.

User Interface

The most significant change in the reworked user interface is the reorganization of the 3D structure administration itself. Logical assemblies are now supported; the parts of such a component may be built of different materials. Materials properties are administered separately, either project oriented or in a central material database. The selection of multiple objects directly in the drawing frame or in the navigation tree is now supported too, allowing the simple assignment of properties to, or the geometrical transformation of, a group of objects.

Interoperability with CAD/EDA

| ||||||

The focus of the development has been on the full integration of CST MWS into the workflow by providing links to electronic design automation (EDA) and CAD tools. The import/export filter for the generic 3D formats STEP, SAT, IGES and STL as well as the 2D format DXF have all been revised. Besides the CATIA4® and Coventor Ware imports, the Pro/E® import has been updated to read-in (encrypted) data up to Version 2002. Other imports of native CAD formats will follow soon. Besides the human data set, which has been available for some time, the import of nearly any voxel data is now supported. The set of 2D imports is completed by GDSII, Gerber and a new Sonnet em® import.

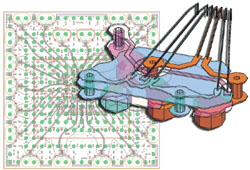

Also, the link to Agilent's ADS was a first step along the path of integrating CST MWS into other design environments. Brand new is the ability to exchange data with CADENCE Allegro and APD. Users can export data via CADENCE's GUI directly into a native file. The parameterization as well as the organization in assemblies is maintained and easily accessible through the interface (see Figure 1).

Version 5, in turn, provides its simulation results to other tools in various ways. The primary result — the generalized S-parameters — can be accessed directly, but may also be exported in TOUCHSTONE® format, where the design tool's very fine frequency resolution can be reduced by neglecting weak couplings between different ports or by downsampling S-parameters. Existing users will already be familiar with the implemented broadband Spice model, which realizes transmission lines between ports including losses and couplings directly from the full wave simulation. With Version 5, a new Spice extraction scheme, based on Model Order Reduction (MOR), is available. This export is applicable to arbitrary topologies and behaviors. Stability and passivity is guaranteed even if the model is used outside the calculated 3D frequency range.

Method and Mesh Selection

CST MWS is based on the finite integration technique (FIT), a very general approach, which first describes Maxwell's equations on a grid space, maintaining properties like energy conservation, and then forms the specific differential equations like the Poisson or Wave equation. FIT can be written in the time domain as well as in the frequency domain. It is not restricted to a certain grid type; Cartesian, structured grids are supported as well as general nonorthogonal ones (tetrahedral, for example). Here we have the first 3D EM simulator that allows the user to switch to the method and mesh that is most appropriate to the simulation task.

In the time domain an explicit time integration scheme is used that can be most efficiently supported by a Cartesian grid. In an effort to improve the structural representation of arbitrarily formed geometries in these cubic cells the Perfect Boundary Approximation (PBA)® has been invented and applied. PBA enables the division of one cubic cell into two parts, taking into account the real, geometrical filling state of the two materials. Thus, the thickness of metallic sheets or strip lines, for example, can be considered within one grid cell, without explicitly meshing it.

Figure 2 shows geometry approximation techniques being demonstrated on a solid (a) and a hollow (b) sphere with cylindrical drilling. The solid model is well represented with PBA alone, while the hollow model requires TST in order to represent the thickness of the metal sphere correctly.

| ||||||

The Thin Sheet Technique (TST),™ an extension to PBA, allows the independent treatment of two dielectric parts of a cell, separated by a metallic sheet. Now structures like arbitrarily shaped housings or thin inclined shields can be modeled with minimum effort.

| ||||||

Version 5 introduces the Multilevel Subgridding Scheme (MSS).™ It allows mesh lines to start and be terminated anywhere in the simulation area. The method fits the shape of the individual objects with nested, conformal layers of increasingly finer mesh (see Figure 3). Here MSS is applied to the same structures as in Figure 2. There are three conformal layers of mesh refinement. For the solid sphere (a), the metallic part is not modeled. PBA and TST also work inside the subgrids. Also, metallic regions can be excluded from the calculations, as is shown in Figure 4, where only the vacuum part of the 16 port waveguide splitter is meshed.

| ||||||

Another important feature is that meshing is based on an expert system. This first detects metallic edges and treats the field singularities as appropriate, and then guarantees that the required sampling of the wave is realized, no matter which material it propagates through. Also, it attributes mesh properties to objects, allowing them to move together for parameter studies and optimizations. The SmartGrid™ meshing technology, which encompasses the innovative PBA, TST, MSS and the implemented expert system meshing, is fundamental to the simulation performance.

Time Domain

The Time Domain Solver calculates the broadband behavior of electromagnetic devices in one simulation run with an arbitrarily fine frequency resolution, and without missing any resonance peaks. When exciting multiple ports, each port can be driven with an individual signal. Database systems are now available for the management of materials and excitation signals. This means that users can centrally store and retrieve their own data when desired. Version 5 now features internal ports as applied to the Yagi array. Besides the degree of freedom in modeling, internal ports can improve the accuracy of Farfield calculations. Also, the time domain solver makes use of Debey, Drude and Lorentz models to cover broadband frequency dependent materials. Gyrotropic media, such as ferrites in circulators, can also be simulated.

Frequency Domain

Similarly, the Frequency Domain Solver now features an adaptive frequency sweep that calculates the broadband response of a device with a minimum number of automatically selected frequency samples. For broadband simulations using periodic boundary conditions, the geometrical scan angle may be used instead of the electrical phase shift to set up the radiation direction. Particular attention has been paid to the port mode solver. CST MWS comes with a periodic (Floquet-mode) boundary port mode solver that delivers the highest accuracy for wide radiation angles, especially for phased array calculations. Since the plane wave can be initiated from the periodic boundary port, the illumination of frequency selective surfaces (FSS) can easily be simulated from arbitrary angles. The port mode solver is also capable of dealing with lossy materials.

Eigenmode Solver

In addition to the present subspace method, a Jacobi-Davidson (JD) algorithm has been implemented. The JD solver is able to find the eigenmodes of cavities loaded with dielectrics with large loss tangents. The Eigenmode Solver features periodic boundary conditions for the calculation of slow wave structures, for example, and a modal analysis that allows the derivation of S-parameters of highly resonant structures such as filters. The modal analysis is supported by a frequency sweep algorithm that summarizes the contributions of the higher modes to the band of interest. The application of the Eigenmode Solver is shown in Figure 5.

| ||||||

Distributed Computing

Another key feature is a distributed computing mechanism that makes use of available resources in the network. There are two models available. First, the multi-port model — the time domain solver requires up to n-runs in order to derive the full S-matrix of an n-port. These runs can be easily started in parallel on different machines. The second model is for parameter studies and optimizations. Here, the same structure is simulated with geometrical modifications. Again these simulations can be distributed over the network. Results are collected in the central front-end, new tasks for the now idle machines are created and the next set of runs is launched. This kind of parallelization delivers a speed-up that is proportional to the number of participating computers. Figure 6 illustrates a typical application for distributed computing.

| ||||||

Post-processing

Farfield evaluation capabilities have also been dramatically extended and the reference coordinate system can now be arbitrarily rotated. Ludwig transformations (elevation over azimuth, azimuth over elevation, horizontal and vertical fields), phase plots and phase center calculations complete the set of features. CST MWS is equipped with time domain farfield probes that record the field value outside the calculation domain. The farfield approximation can also be switched off, so that the near field at a reference distance is available.

The usage of post-processing templates has also been introduced. These templates can record user-defined quantities after every simulation (the broad band gain after an antenna simulation, for example), evaluate certain secondary results (like the maximum of the broadband gain) and use these results for the automatic optimization

After the calculation of the broadband S-matrix of a device, which is usually done with a sine modulated Gaussian pulse, the capability exists to replace this excitation signal by another, including digital pulses to create eye-diagrams, useful for signal integrity considerations.

Open Design Environment

CST MWS is completely embedded in CST DESIGN STUDIO™ (CST DS), an open design environment which allows the combination of solutions from those EDA tools that are best suited for particular subcomponents. Its goal is the seamless integration of different techniques within a single unifying framework.

Also, through an embedded subset of APLAC solver technology, especially selected for EM/circuit co-simulation tasks, circuit components can be treated with a variety of techniques such as mixer or amplifier analysis, harmonic balance and noise analysis. The CST Design environment has access to, and full parametric control of, geometrical dimensions, material properties and other settings of each subcomponent. Also, an intelligent interpolation scheme exploiting results from previous simulations significantly accelerates the optimization process of a multi-parameter problem.

Conclusion

CST MICROWAVE STUDIO Version 5 offers groundbreaking new features, which have been implemented with a microwave design engineer's needs in mind. The aim throughout has been to augment his or her throughput while retaining the unique user-friendliness of the software.

Reference

- F. Demming-Janssen, T. Bertuch, et al., "Time Domain Simulation of Conformal Antennas Using the Finite Integration Technique (FIT) with PBA Geometry Discretisation and Local Time Step Adaptive Sub-gridding," Proceedings of the 3rd European Workshop on Conformal Antennas, 2003.

CST GmbH,

Darmstadt, Germany

+ 49 (0) 6151 7303-30;

CST of America,

Wellesley Hills, MA

(781) 416-2782, www.cst.com.

Circle No. 300