Fig. 1 No nut quick-test adapter.

Quick Test adapters, also commonly referred to as push-on adapters, quick connect adapters, quick-lock adapters and snap-on adapters, have been used by the microwave industry for years at low frequencies. While adding a level of convenience not found in traditional RF connectors, these adapters suffered from a degraded electrical performance, poor repeatability and reduced life. As such, adapters of this type were often avoided by those seeking a reliable connection. In response to customer demands for high-frequency, extremelyrepeatable, long life precision push-on adapters, Maury Microwave invented the precision push-on/pull-off 3.5 mm adapter, the QT3.5mm™. The QT3.5mm is a patented design, based on Maury’s metrology and precision adapter technology and is compatible with SMA, 3.5 and 2.92 mm connectors. The QT3.5mm is available in four configurations: no nut, 3/8" diameter nut, 9/16" diameter nut and guide sleeve.

Fig. 2 3/8" and 9/16" diameter nut quick-test adapters.

No Nut

The no nut quick-test adapter (see Figure 1) enables push-on/pull-off operation and allows for a full 360 degree rotation after connection is made, greatly increasing the flexibility of installations. With a rated life of over 3000 connect/disconnect cycles, the no nut QT3.5mm maintains a S-parameter repeatability of over 40 dB.

3/8" and 9/16" Diameter Nut

The 3/8" and 9/16" diameter nut quick-test adapters (see Figure 2) not only act as quick-test adapters with push-on/pull-off operation, but also have the increased accuracy of a threaded connection. With only a 1.5-turn rotation, the threaded nut will engage and prevent accidental slippage during use. Machined wrench flats allow the use of torque wrenches for metrology and calibration applications. With a rated life of over 3000 connect/disconnect cycles, the 3/8" and 9/16" diameter nut QT3.5mm maintains a S-parameter repeatability of over 50 dB when hand- or wrench-torqued.

Fig. 3 No nut quick-test adapter with guide sleeve.

Guide Sleeve

The no nut quick-test adapter allows for a full 360 degree rotation after connection is made, greatly increasing the flexibility of installations. The additional guide sleeve (see Figure 3) enables self-alignment making it ideal for automated test stations. With a rated life of over 3000 connect/disconnect cycles, the no nut guide-sleeve QT3.5mm maintains a S-parameter repeatability of over 40 dB.

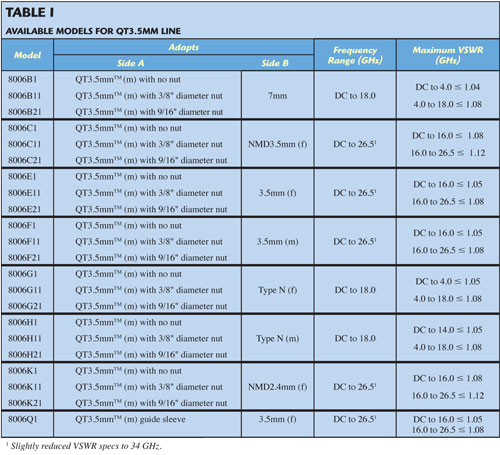

Available ModelsNo nut, 3/8" diameter-nut, 9/16" diameter-nut and guide-sleeve models are available to adapt with Type-N connectors to 18 GHz, 7 mm connectors to 18 GHz and 3.5 mm connectors to 26 GHz with excellent insertion loss and VSWR. Ruggedized 3.5 and 2.4 mm NMD options are also available for use on test ports (see Table 1).

Independent Test Results

Independent testing was carried out on the 8006Q1 QT3.5mm guide sleeve adapter at 3000 connect/disconnect cycles. While rated with a return loss repeatability of better than 40 dB without use of a torque nut or wrench, independent testing proved a repeatability better than 56 dB to 10 GHz, 49 dB to 20 GHz and 47 dB to 26.5 GHz after 3000 connect/disconnect cycles. Similar results surpassing rated specifications were achieved for insertion loss magnitude repeatability, with a low variance of 0.03 dB to 10 GHz, 0.04 dB to 20 GHz and 0.06 dB to 26.5 GHz after 3000 connect/disconnect cycles, without use of a torque nut or wrench. As with magnitude, insertion loss phase repeatability surpassed specifications with a low variance of only 0.16 degrees to 10 GHz, 0.31 degrees to 20 GHz and 0.45 degrees to 26.5 GHz after 3000 connect/disconnect cycles, without use of a torque nut or wrench. Maximum life was noted as 10,000 connect/disconnect cycles.

Industry Use/Applications

The convenient push-on/pull-off connector offers excellent repeatability, a long operating lifespan and increased throughput (up to 10× faster than mate-torque-demate) making it ideal for use in high volume test/production environments such as those found in component manufacturers (filters, attenuators, cables, couplers, etc) and those testing device assemblies in high volume (cell phones, radios, medical RF devices, etc). Commercial and military field operations can also benefit from a push-on/pull-off connector where using a torque wrench might not be convenient or even possible.

Maury Microwave,

Ontario, CA

(909) 987-4715

www.maurymw.com