Acoustics Module Upgrade

Major upgrade to COMSOL’s acoustics module enables realistic acoustic simulations of mobile devices and automotive components

New capabilities enable virtual prototyping of microphones, mobile devices, piezo-acoustic transducers, mufflers, and particulate filters with unprecedented detail and ease of use.

BURLINGTON, MA (July 13, 2011) — COMSOL, Inc., today announces the release of a major upgrade of its add-on Acoustics Module for its flagship product COMSOL Multiphysics. This latest version of the Acoustics Module offers new capabilities and expanded multiphysics user interfaces for simulating thermoacoustic effects, poroelastic waves, acoustic-shell interactions, and piezo-acoustic devices. The new version of the Acoustics Module is available immediately.

“This release of the Acoustics Module brings a new level of predictive power to acoustic simulations,” says Dr. Mads J. Herring Jensen, technical product manager for acoustics at COMSOL. “For the first time, manufacturers of acoustic devices for smart phones, hearing aids, and earpieces can perform thermoacoustic simulations with an industry-standard commercial multiphysics software package. The ability to combine such simulations with electrical circuits and structural vibrations raises the bar for state-of-the-art acoustics simulations of mobile devices.”

Additional application areas for the Acoustics Module, adds Herring Jensen, include speakers, microphones, and sonar devices as well as noise control in areas such as muffler design, sound barriers, and building acoustics. The module's physics interfaces provide easy-to-use tools to model acoustic pressure wave propagation in air, water, and other fluids. The Acoustics Module also enables users to model vibrations and elastic waves in solids and piezoelectric materials, as well as their bidirectional interaction with a surrounding fluid, easily.

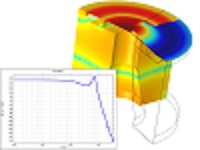

This titanium speaker cone surrounded by air and set in an infinite baffle showcases the new acoustic-shell interaction user interface for solving acoustic pressure in air and structural deformations in a shell. The structural vibrations automatically act as a sound source and the pressure force is coupled back to act on the shell. Applications for this type of simulation range from speakers to ship acoustics.

“Our analysis of acoustic applications has ranged from the design of miniature microphones and loudspeakers, development of MEMS-based photoacoustic and piezo-acoustic technologies, optimization of room design for acoustic energy distribution, and identification of sources for noise emission. Each of these applications has required the implementation of additional functionality into COMSOL Multiphysics to provide accurate analysis of real world systems,” comments Dr. Jeffrey S. Crompton, Principal of AltaSim Technologies, Columbus, OH. Through his company, Dr. Crompton provides a range of products and services such as customized computational analyses and the development of functional prototypes for market sectors including medical devices, defense, petrochemical refining, automotive, and materials development.

The new capabilities of the Acoustics Module are fully compatible with all the COMSOL add-on modules. Any acoustics phenomena can link to any other physics effect – a feature that is crucial for real-world precision simulations of acoustics devices. “The upgrades in this version of the Acoustics Module will provide all users with access to critical functionality associated with analysis of acoustics phenomena. These additions greatly enhance the flexibility of COMSOL Multiphysics and will allow users to integrate relevant phenomena more easily and develop more accurate simulations of real-world performance. This will benefit all developers of new products and technologies and increase the rate at which new technologies can reach the marketplace,” concludes Dr. Crompton.

Mobile Devices and Thermoacoustics Simulations

The new modeling tools for thermoviscous acoustics in the Acoustics Module enable highly accurate simulation of miniaturized speakers and microphones for hand-held devices. The ability to include thermoviscous acoustics, also known as thermoacoustics, in a simulation is necessary to accurately model acoustics in geometries with small dimensions. Near walls, viscosity and thermal conduction become important considerations because they create a viscous and a thermal boundary layer where losses are significant. The new thermoacoustics capabilities of the Acoustics Module take such effects fully into account.

A diesel particulate filter (DPF) is designed to remove soot (diesel particles) from the exhaust of diesel engine vehicles. Although a DPF's main function is filtering exhaust flow, it is made with porous materials that have acoustic damping properties that can affect the muffler system. These effects, in turn, can affect the performance of other components in the vehicle. In this poroelastic wave simulation, the transmission loss in dB is computed for the range 0-2000 Hz.

Automotive Components and Poroelastic Waves

When creating a virtual prototype of an automotive component with a fibrous or porous filling, how to represent the filling's acoustic damping properties has been a challenge. The Acoustics Module’s new poroelastic wave functionality offers a new and more accurate approach to this challenge.

With traditional simulation methods, engineers confronting this challenge would approximate their filling with a so-called equivalent fluid model. This approach often produced an approximation of reality that was too rough. Using the new poroelastic wave functionality in the Acoustics Module, engineers enter solid and fluid properties into their model directly and the damping is accounted for in the simulation automatically.

“Determining the damping properties of an equivalent fluid model requires a lot of engineering experience,” comments Dr. Herring Jensen. “Even if you've been successful in the past, it is often not valid for the full range of studied parameters. It will never be as accurate as the Acoustics Module's new poroelastic model, which can be used to model virtually any porous medium for a wide range of frequencies.”

Acoustics Module Version 4.2 Highlights

• Enables rapid prototyping and optimization of acoustic devices and transducers

• Accelerates the investigation of acoustic-induced vibration phenomena in devices

• Ideal for the study of material-dependent acoustic phenomena

• Works with real CAD geometry models and leading CAD software and formats

• User interfaces for:

o Simulations in the time and frequency domains

o Pressure acoustics

o Solid-acoustic interactions

o Piezo-acoustic devices

o Poroelastic and elastic waves

o Thermoacoustics

• Combines with the Structural Mechanics Module for shell-acoustic interactions with dedicated user interfaces

• Combines with the AC/DC Module for simulations such as electromagnetics and electrical circuits

For more information visit the company’s website by clicking the link below our logo on this page.