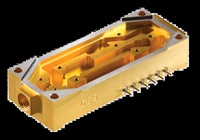

Hermetic Aluminum Housings

Litron’s vertically integrated operations on hermetic aluminum housing provide the flexibility expected from a true partner. Specializing in aerospace and defense, microwave packages can be manufactured in various configurations. MASTERCAM CADCAM software allows Litron’s customer-driven team to easily convert native computer drawings. CNC milling and turning delivers tight tolerances as precise as ± 0.001. Providing one-stop shopping, feedthru installation is also available. Lid manufacturing is additionally offered upon customer request. These processes are conveniently supported by on-site thermal shock testing, helium leak testing, and precision machining. To ensure accurate design, cohesive preform bond unmatched in the industry, and zero rework, Litron partners with its customers to evaluate the best machining strategy. The energy that Litron’s experienced staff dedicates to each project yields the highest standard of production, which they personally demand. Quality and integrity of parts are thoroughly verified with 100% inspection on a 10X microscope and gold plating inspection includes 100% bake testing. Furthermore, a quick turnaround time and supply chain management allows for on-time delivery. With consistent excellence in manufacturing at competitive pricing, Litron gives confidence to its customers and the execution expected of their team.